Installation and Operation Manual

X-TMF-5800S-MFC-eng

PN 541-C-051-AAG

November, 2008

Models 5800-S

22

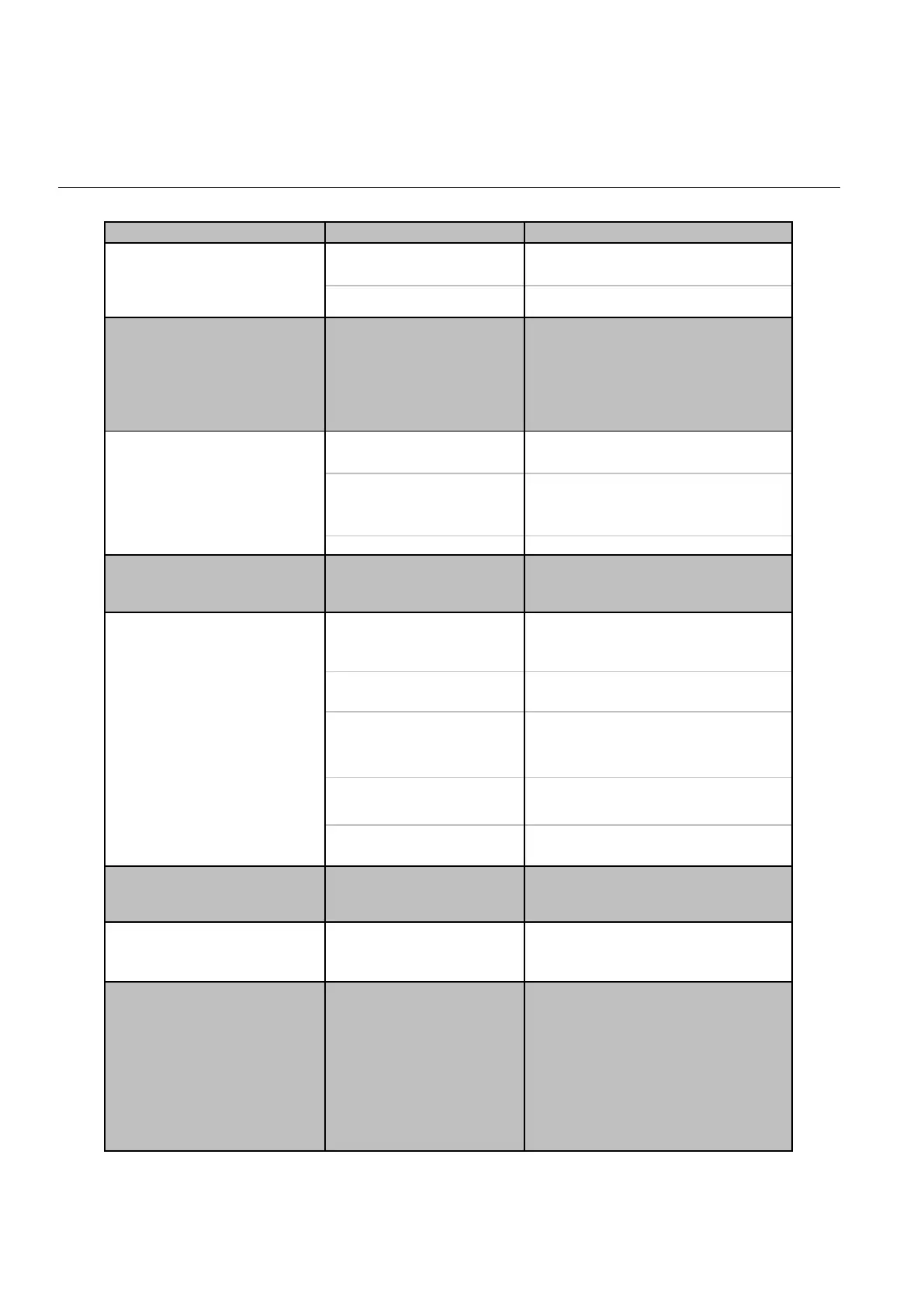

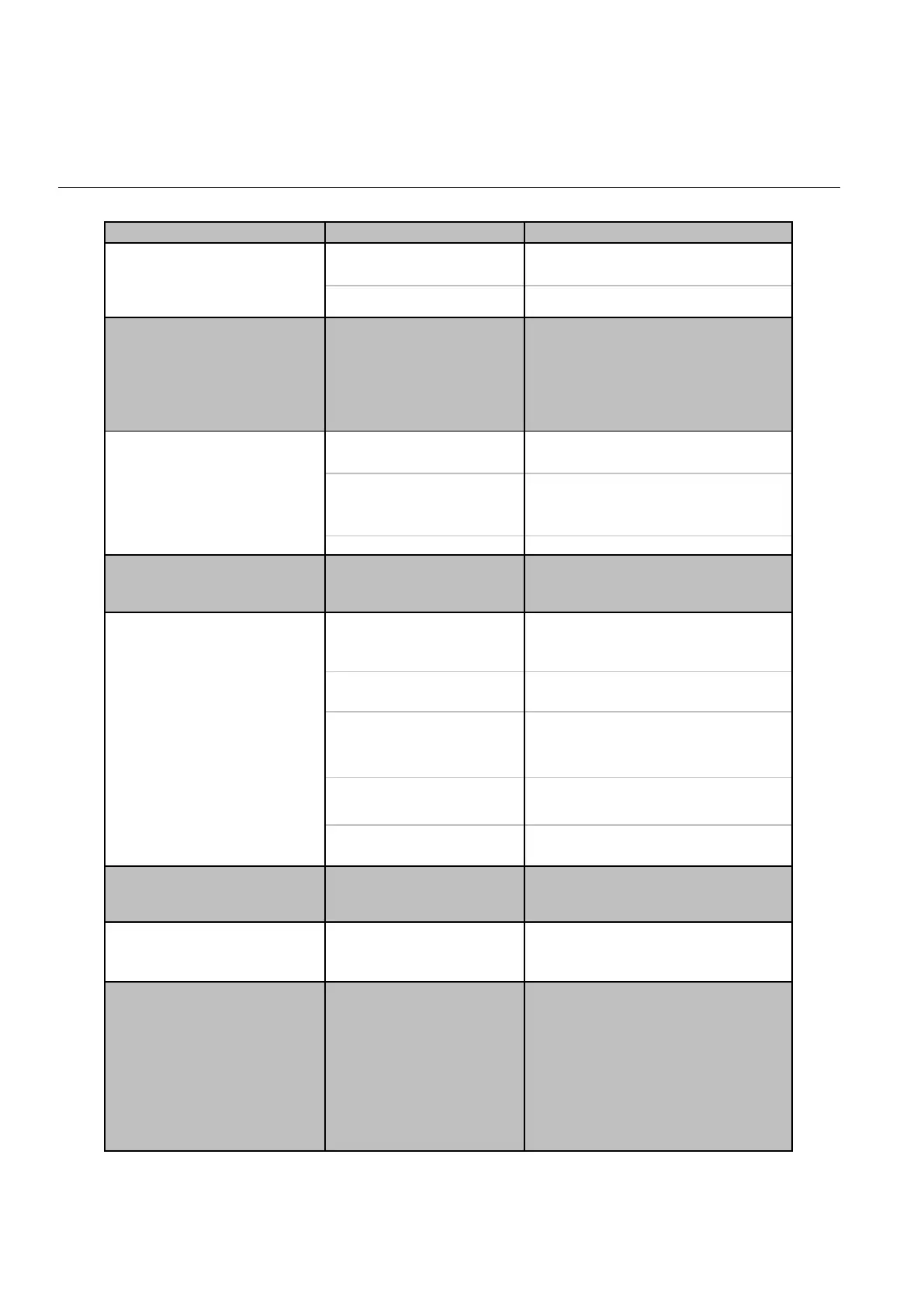

Table 4-1: Troubleshooting

Trouble Possible Cause Check/Corrective Action

Clogged Sensor Clean sensor. Refer to cleaning

procedures (Section 4.3).

Defective electronic board

Clogged Control Valve Clean the control valve (Section 4.3)

or return the device to the factory

Valve override input is

grounded

Check the valve override input

(pin 12)

Defective electronic board Contact Brooks Instrument.

Valve leaks or is stuck

open (applicable to MFC)

Clean and/or adjust control valve

(Section 4.3).

+15V applied to the valve

override input (applicable to

MFC)

Check the valve override terminal

(pin 12)

Defective electronic board Contact Brooks Instrument.

Output signal follows Set point

at higher set points but will not

go below 2%

Control valve leaks or is

stuck open

Clean the control valve or return the

device to the factory (Section 4.3)

Insufficient inlet pressure or

pressure drop

Adjust pressures, inspect in-line

filters and clean/replace as

necessary

Partially clogged sensor Clean sensor, see cleaning

procedures (Section 4.3)

Partially clogged valve

(applicable to MFC)

Clean the control valve (Section 4.3)

or return the device to the factory,

see cleaning procedures

Valve out of adjustment

(applicable to MFC)

Adjust valve, see calibration

procedures (Section 4.4)

Valve guide spring failure

(applicable to MFC)

Controller oscillates (see below)

Instrument grossly out of

calibration. Flow is higher than

desired.

Partially clogged sensor Clean sensor, see cleaning

procedures (Section 4.3)

Instrument grossly out of

calibration. Flow is lower than

desired.

Partially clogged restrictor Replace or clean restrictor.

Pressure drop or inlet

pressure deviates from

calibrated values

Adjust pressures

Oversized orifice Check orifice size

Valve out of adjustment Adjust valve, see calibration

procedures (Section 4.4.)

Unstable inlet pressure Check external pressure regulator

Defective p.c. board Contact Brooks Instrument

Controller oscillates

(applicable to MFC)

Output stays at zero

(regardless of Set point) and

there is flow through the

meter/controller

Flow can not be achieved

regardless of Set point.

(applicable to MFC)

Output signal stays at approx.

5.25 Vdc or 21 mA (regardless

of Set point) and there is flow

through the meter/controller

Output signal follows Set point

at lower set points, but does

not reach full scale

Section 4: Maintenance

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Loading...

Loading...