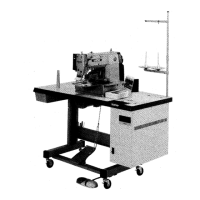

BAS-311HN, BAS-326H

CONTENTS

1. NAMES OF MAJOR PARTS ................ 1

2. SPECIFICATIONS ................................ 2

3. INSTALLATION.................................... 3

3-1. Table processing diagram ................................ 3

3-2. Installing the control box................................... 4

3-3. Installing the oil pan.......................................... 4

3-4. Installing the machine head.............................. 5

3-5. Installing the LCD panel ................................... 8

3-6. Installing the two-pedal foot switch ................. 9

3-7. Connecting the cords........................................ 9

3-8. Connecting the ground wire.............................. 13

3-9. Connecting the power cord............................... 14

3-10. Installing the cotton stand............................... 17

3-11. Installing the pneumatic unit

(pneumatic work clamp specifications)............. 18

3-12. Installing the eye guard .................................. 19

3-13. Installing the side cover and rear cover.......... 19

3-14. Lubrication ...................................................... 20

3-15. Installing the machine head fixing bolt ........... 21

3-16. Checking the machine head switch................ 21

4. PREPARATION BEFORE SEWING.....22

4-1. Installing the needle.......................................... 22

4-2. Threading the upper thread .............................. 23

4-3. Winding the lower thread.................................. 25

4-4. Installing the bobbin case................................. 27

4-5. Thread tension.................................................. 28

4-5-1. Lower thread tension ........................... 28

4-5-2. Upper thread tension ........................... 29

4-5-2-1. Upper thread tension

(Medium-weight materials

specifications <-03[]>,

Heavy-weight materials

specifications <-05[]>) ................... 29

4-5-2-2. Upper thread tension

(Seatbelt specifications <-07A>) ... 29

4-6. Starting up ........................................................ 30

5. SEWING................................................31

5-1. Sewing .............................................................. 31

5-2. Using the STOP switch..................................... 32

6. CLEANING ...........................................33

6-1. Cleaning the rotary hook...................................33

6-2. Cleaning the control box air inlet ports .............34

6-3. Draining the oil ..................................................34

6-4. Cleaning the eye guard.....................................34

6-5. Checking the needle .........................................34

6-6. Lubrication.........................................................34

6-7. Applying grease

(Feed mechanism BAS-311HN) .......................35

7. STANDARD ADJUSTMENTS ..............37

7-1. Checking the machine head switch ..................37

7-2. Adjusting the sensitivity of the thread

breakage sensor...............................................38

7-3. Thread take-up spring.......................................39

7-4. Arm thread guide R...........................................39

7-5. Adjusting the needle bar height ........................40

7-6. Adjusting the needle and rotary hook timing.....40

7-7. Adjusting the driver (needle guard) position .....41

7-8. Adjusting the clearance between the

needle and rotary hook tip ................................41

7-9. Adjusting the shuttle race thread guide ............41

7-10. Rotary hook lubrication amount ......................42

7-11. Adjusting the position of the movable knife ....42

7-12. Replacing the movable and fixed knives ........44

7-13. Installing the feed plate ...................................45

7-14. Adjusting the thread wiper ..............................45

7-15. Intermittent presser foot installation position ..46

7-16. Adjusting the intermittent presser foot ............46

7-17. Adjusting the work clamp lift amount ..............48

7-18. Adjusting the air pressure ...............................48

7-19. Setting method for standard depression

strokes (foot switch)........................................49

7-20. If processing the work clamps and the

feed plate to a shape that matches the

sewing pattern ................................................51

8. LIST OF ERROR CODES.....................53

9. TROUBLESHOOTING..........................59

Loading...

Loading...