Bunn-O-Matic Corporation

13

Machine Function and Operations

Main Control Board

The main control is the brain of the brewer. In a digital brewer, the control board is the single

component that contains all of the programming software, it interprets all the data it receives

fromthelevelandtemperaturesensorsandactivatescomponentstofulllthosedemands.

The main control board responds to the users input through the membrane switch or mechan-

ical switches and activates and controls the brew cycle.

Filling System

Thellsystemmaintainsthelevelofwaterinthebrewer’stank.Anytimewaterisdrawnoff

ofthetankduringabrewcycleorfromthehotwateroutlet,thellcircuitactivatestorellthe

tank.

Thellsystemconsistsof:

• 120VACsolenoidinletvalveassembly(includesthestrainerandowregulator

• Fillprobe

Water enters the brewer through the water supply line and enters the chassis through a

strainerassembly;thisstrainercontainsanemeshscreentokeepanylargeparticles

fromenteringtheinletvalve.Fromthestrainerthewaterowsthroughthe0.222ow

control device and into the inlet solenoid.

The 120VAC solenoid inlet valve is activated by the control board anytime the

brewercallsforwater.Thevalveopensandallowswatertoow,underline

pressure,tothebottomofthetankwherethesilicontubeconnectstothell

tube.

The control board monitors the level of water in the tank through a low voltage

level probe mounted to the top of the tank. The control board grounds a 2.5VAC

signal to the tank through the water. If it looses this signal, the control board will

activate the inlet valve.

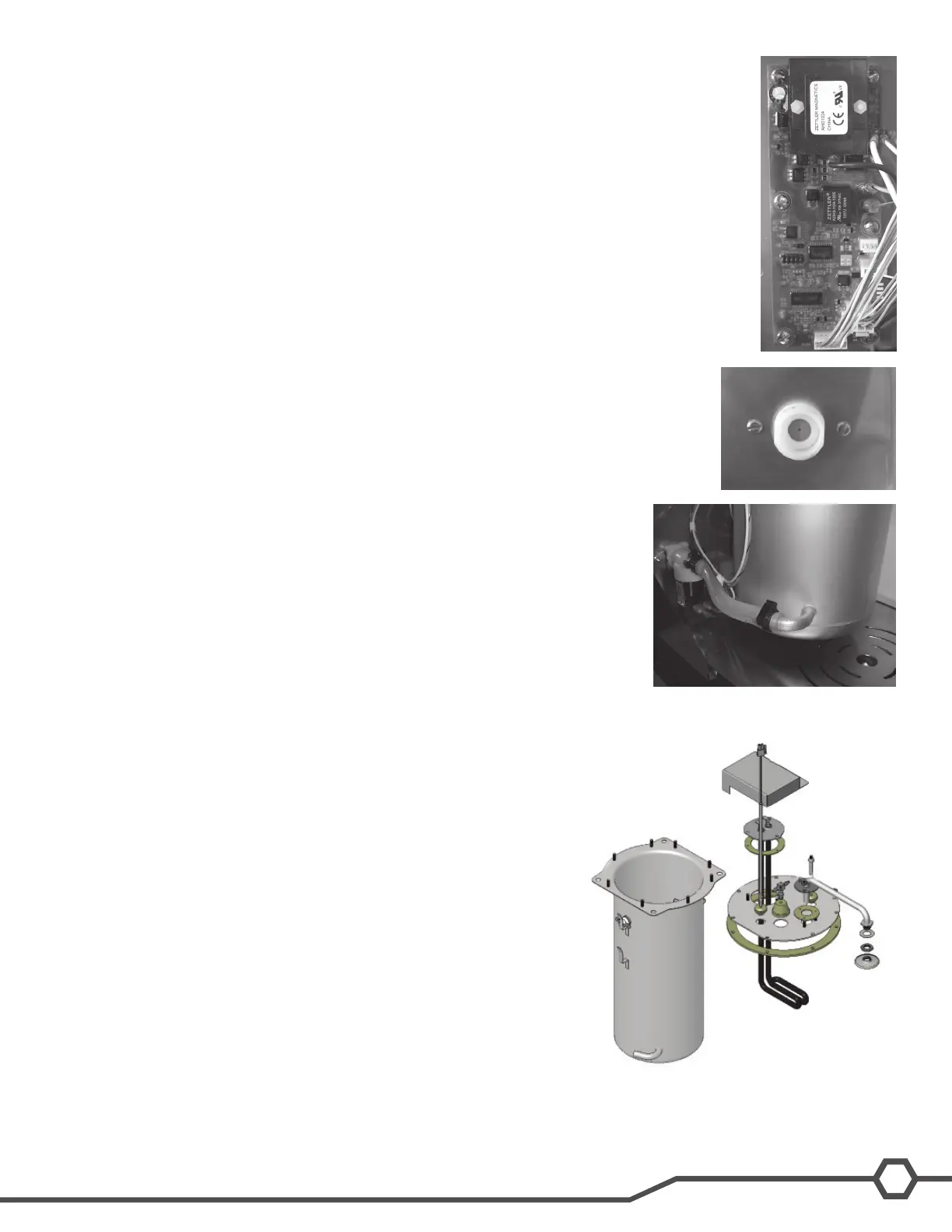

Heating System

Theheatingsystemconsistsof:

• Watertank

• Heatingelements

• High-limitthermostat

• Temperaturesensor

The heating circuit maintains the water in the tank at a preset temper-

ature this ensures that the water is always ready for brewing.

Water for brewing is contained in a 155 oz. stainless steel tank. This

tank contains a 1320W heating element (1850W in the high voltage

machine) that is powered by the line voltage into the machine. The

heating element is controlled by the control board through a relay

mounted on the board. There is a limit thermostat wired in series with

the element that will interrupt the circuit if the water in the tank over-

heats. This limit will open the circuit at 230°F and automatically resets

at 170°F.

The control board monitors the water in the tank by a temperature sensor that is in contact with the water. This

temperaturesensorisadigitalthermistor;thecontrolboardreadsthetemperatureasvalueofresistance.The

temperature sensor allows the control board to activate the heating element when the temperature drops below its

programmed value and shut down the element when the water temperature reaches the programmed holding value.

Loading...

Loading...