SmartWAVE

®

Training Manual

14

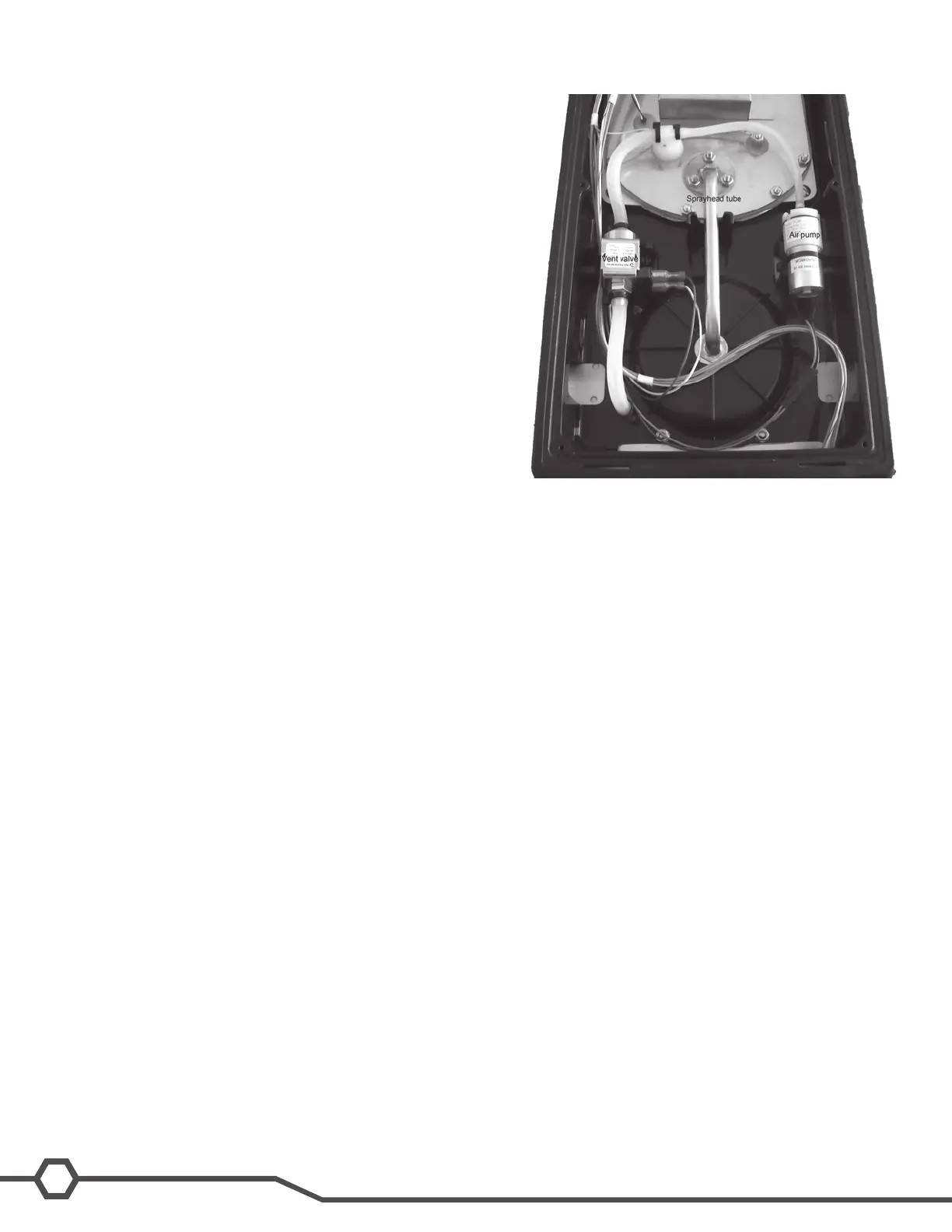

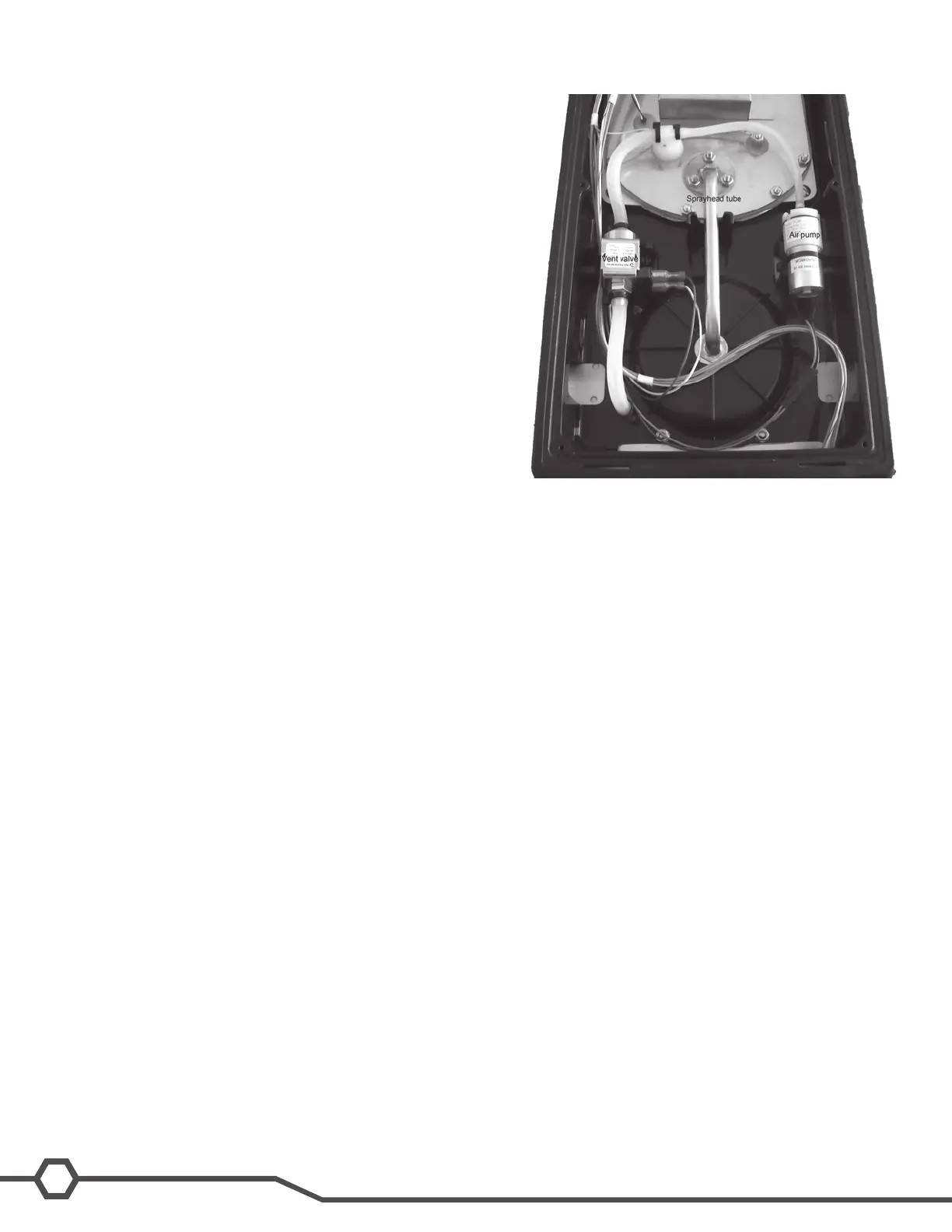

Dispensing System

Thedispensingsystemconsistsof:

• Inletvalve

• Brewtube

• Sprayhead

• Airpump

• Ventvalve

When the operator initiates a brew cycle the inlet valve ac-

tivatestollthewatertank,thecoldincomingwaterinthe

bottom pushes the hot water on the top through the spray-

head tube. Once the tank is full the air pump turns on and the

vent valve begins to cycle, this cycle actions creates varying

pressure in the tank creating a wave action as the water is

dispensed. The wave creates a high level of turbulence in the

coffee leading to superior extraction.

During the brew cycle the water will drop below the level of the

llprobe,thecontrolboardwillshutofftheairpumpandvent

valvetoallowthetanktorellbeforecontinuingthebrewcycle.

This is the normal brewing routine of the SmartWAVE and is

similiar to a pulse brew. Additional pulse brewing, that cycles

the inlet valve, can be programmed.

At the end of the brew cycle the inlet valve is deenergized and the vent valve closes. The air pump remains on to

forcethewaterinthetankoutofthesprayheadtubebelowthellprobe.Therellcircuitthenllsthetanktothell

probe.

The SmartWAVE

®

seriesofbrewersareshippedwitha6-078sprayhead.Thesprayheadistheoutputowregulator

forthebrewer.Thenumberandsizeofholesdeterminestheoutputowrate.Ifthesprayheadischangedtoadiffer-

ent number the brew times will have to be adjusted. The SmartWAVE can use any BUNN sprayhead, including the

17 hole, A change of sprayhead will require adjusting the batch size.

Loading...

Loading...