37

Maintenance, cleaning

WARNING!

Risk of injury from parts jumping out!

Whenthespindleopeningisexposed,theindividualpartsof

thepackingglandarepressedoutatanundenedspeedwhen

thepilotairportsispressurized.

▶ Beforepressurizingwithcontrolair,safeguardtheambientarea

ofthedischargeopening(e.g.placespindleonarmbase).

1

2

Pilotairport

Pilotairport

Fig. 33: Connections

→ Pressoutpackinggland:

Control function A and IPressurizepilotairport1with6–8

bar.

Control function BPressurizepilotairport2with6–8bar.

→ Greasetheindividualpartsofthenewpackingglandwiththe

uppliedlubricant.

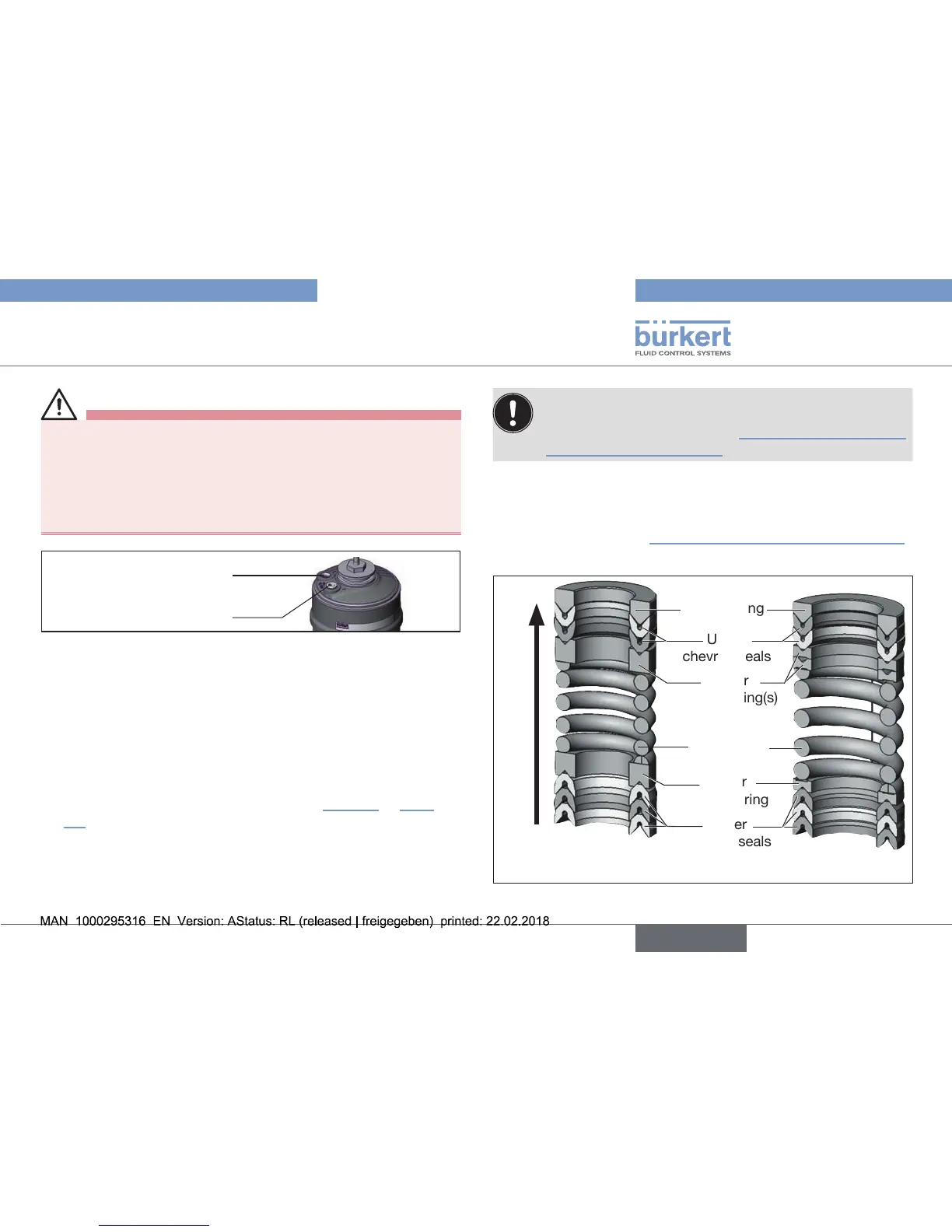

→ Connecttheindividualpartstothespindleinthespecied

directionandsequence(asillustratedin“Fig.34”or“Fig.

35”).

→ Pushpackingglandintothepackingglandtube.

If the valve featuresa PEEK spindle guide (series pro-

ductionstatusuptoApril2012),werecommendreplacing

itwithaVAspindleguide(see“Tab.25:VAspindleguide

forpackinggland”,page42)

→ Greasethreadofthespindleguide(KlüberpasteUH1

96-402).

→ Screwspindleguidebackinusingtheinstallationtool.

Observetorque(see“Tab.19:Tighteningtorquesofspindle”)!

Insertiondirectionfor

packingglandparts

Supportring

Upper

chevronseals

Upper

pressurering(s)

Pressure

spring

Lower

pressurering

Lower

chevronseals

Spindlediameter10mm Spindlediameter14mm

Fig. 34: Seal set for packing gland SP10 / SP14

Loading...

Loading...