20

Installation

Type 3280, 3285

7 INSTALLATION

DANGER!

Risk of injury from high pressure in the system or device.

▶ Before working on the system or device, cut off the pressure and deaerate/drain lines.

Risk of injury due to electrical shock.

▶ Before working on the system or device, switch off the power supply and secure to prevent reactivation.

▶ Observe applicable accident prevention and safety regulations for electrical equipment.

WARNING!

Risk of injury from improper installation.

▶ Installation may be carried out only by trained technicians and with the appropriate tools.

▶ Secure system against unintentional activation.

▶ Following installation, ensure a controlled or defined restart.

7.1 Fluid installation

Installation position: any position, preferably with actuator above and installed vertically with the actuator cover

upwards

→ Clean pipelines and port connections.

→ Install a dirt filter before the valve inlet (≤ 0.3 mm).

NOTE!

Caution risk of breakage.

• Do not use plastic actuator housing as a lever arm.

→ Hold the device with a suitable tool (open-end wrench) on the body and screw into the pipeline.

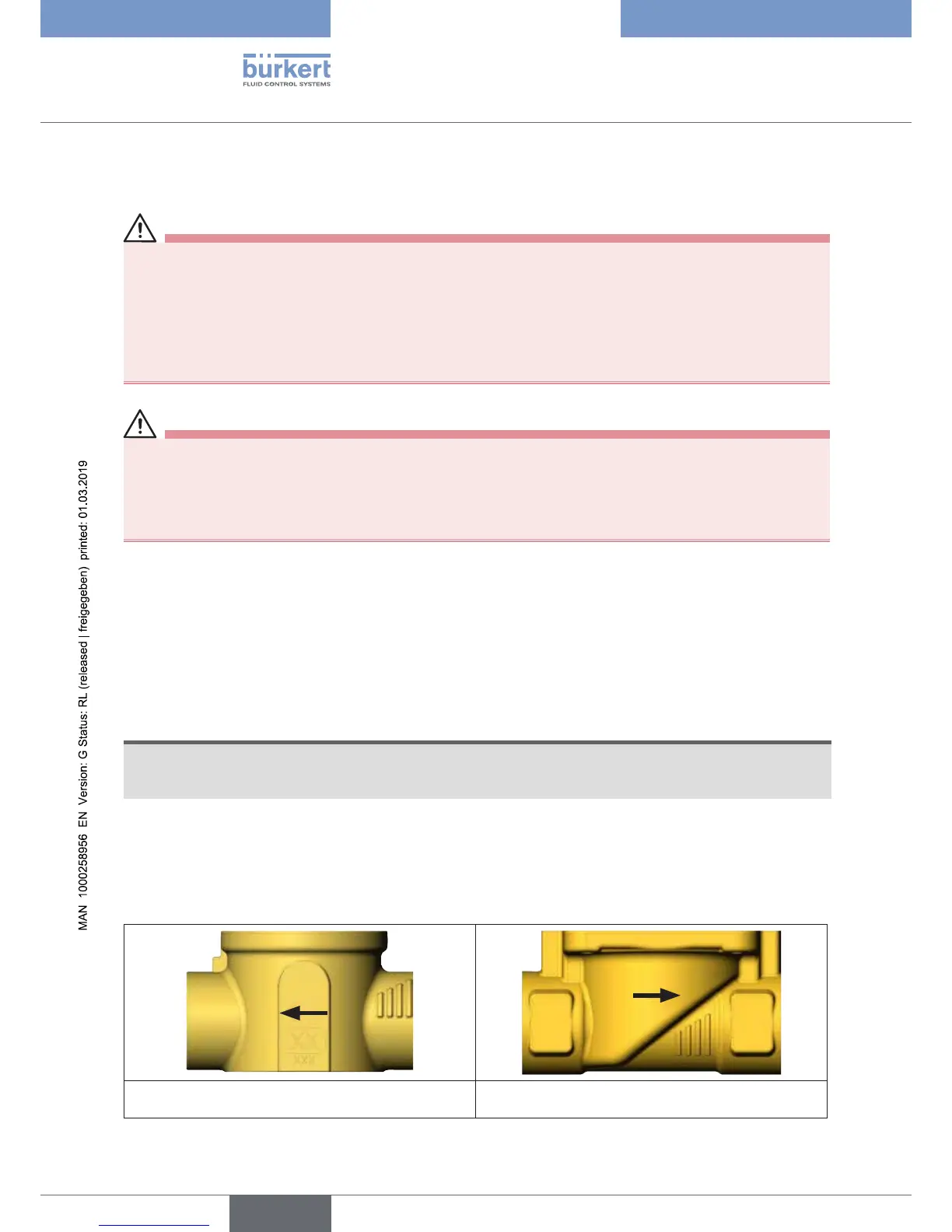

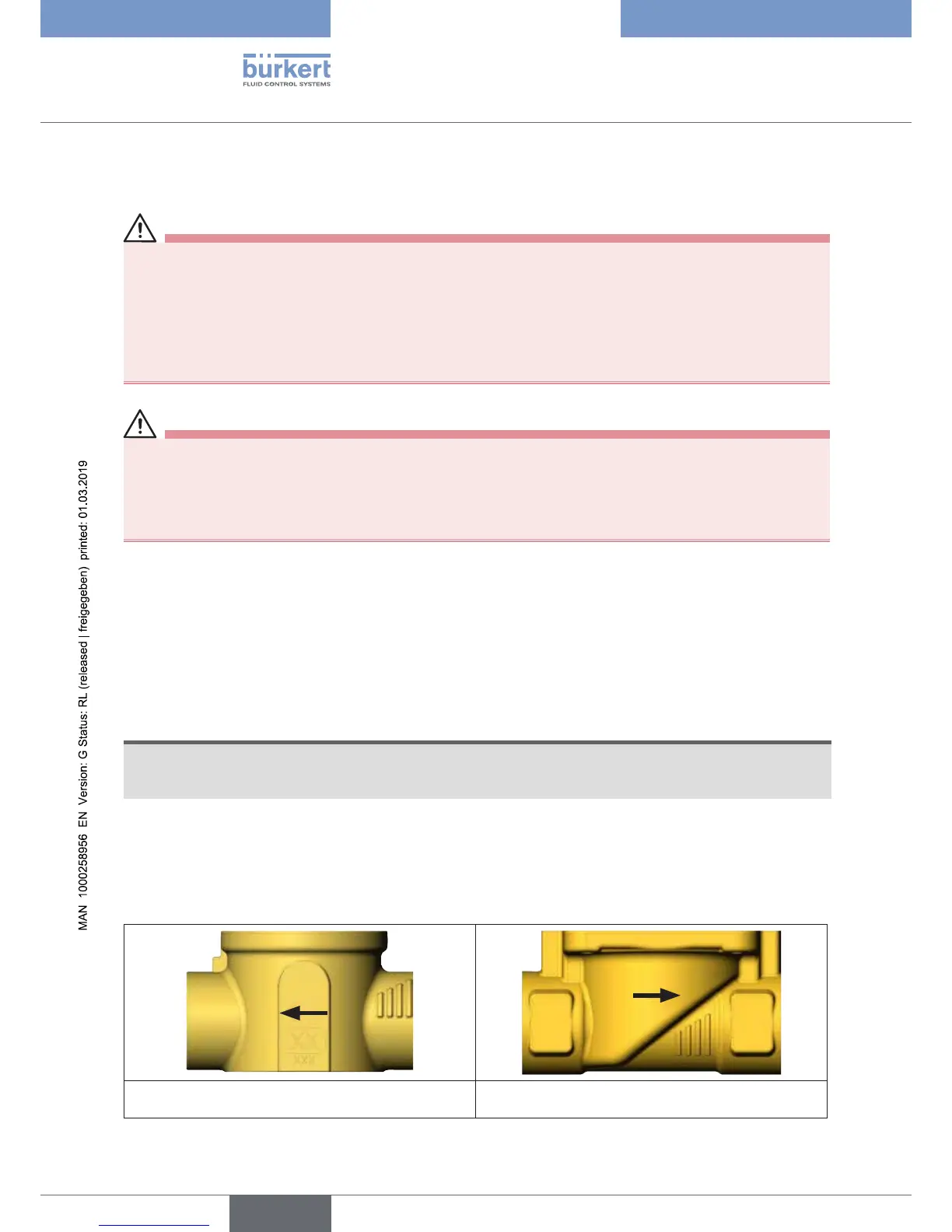

→ Observe flow direction. The arrow on the body indicates the direction of flow.

Type 3280: Flow direction below seat, is always closed against the medium flow;

Type 3285: Flow direction above seat, is always closed with the medium flow.

Figure 8: Direction of flow Type 3280, Flow direction

below seat

Figure 9: Direction of flow Type 3285, Flow direction

above seat

Loading...

Loading...