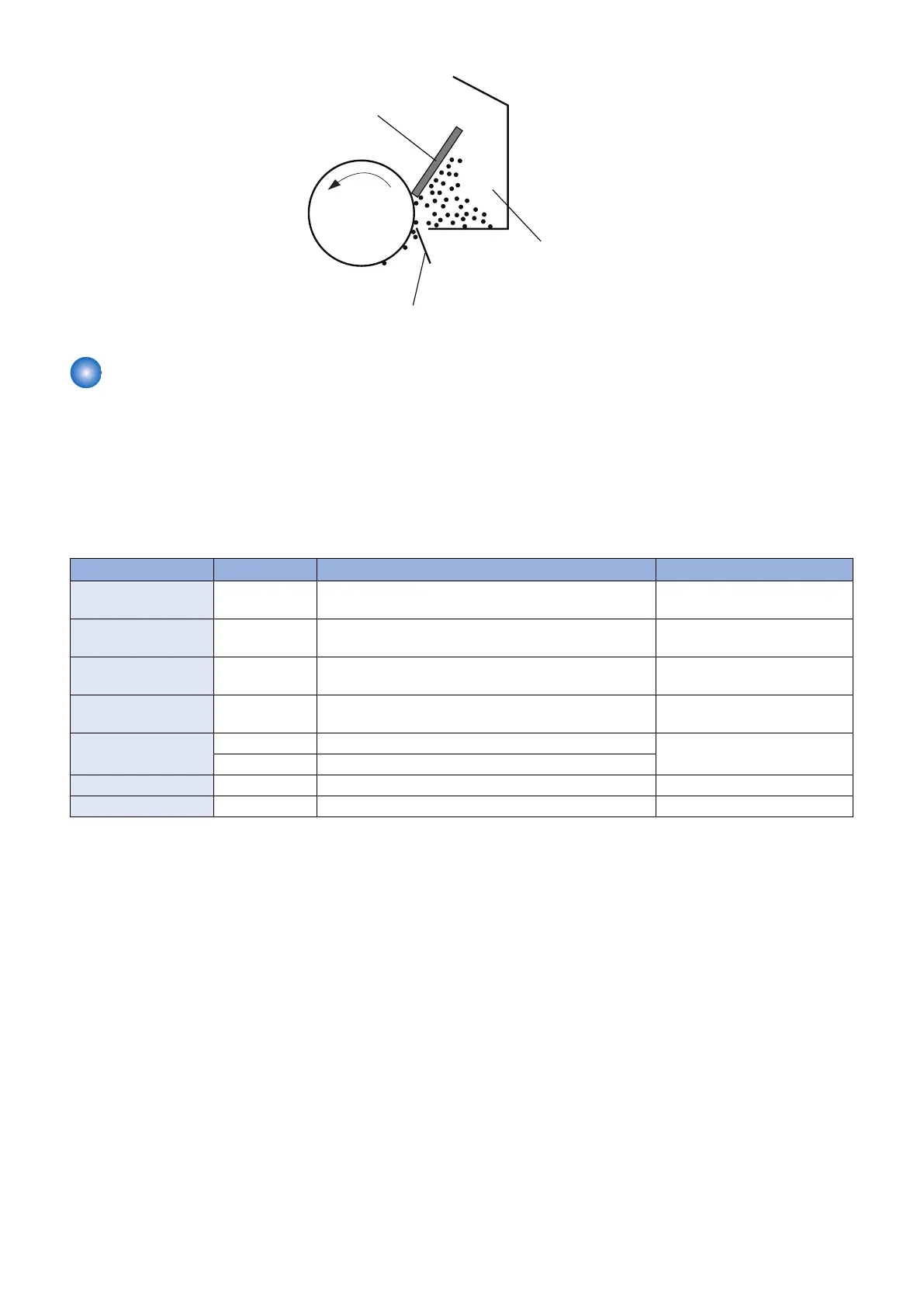

Sweeper strip

Waste toner container

Photosensitive

drum

Cleaning blade

Controls

■ High-voltage power supply control

● Overview

The high-voltage power supply PCBs are to apply high-voltage bias to the primary charging roller, the primary transfer pad, the

secondary transfer external roller, and the ITB cleaning unit. Such high-voltage bias is generated through control by the DC

controller on the high-voltage power supply PCBs.

The figure below shows the high-voltage power source schematically.

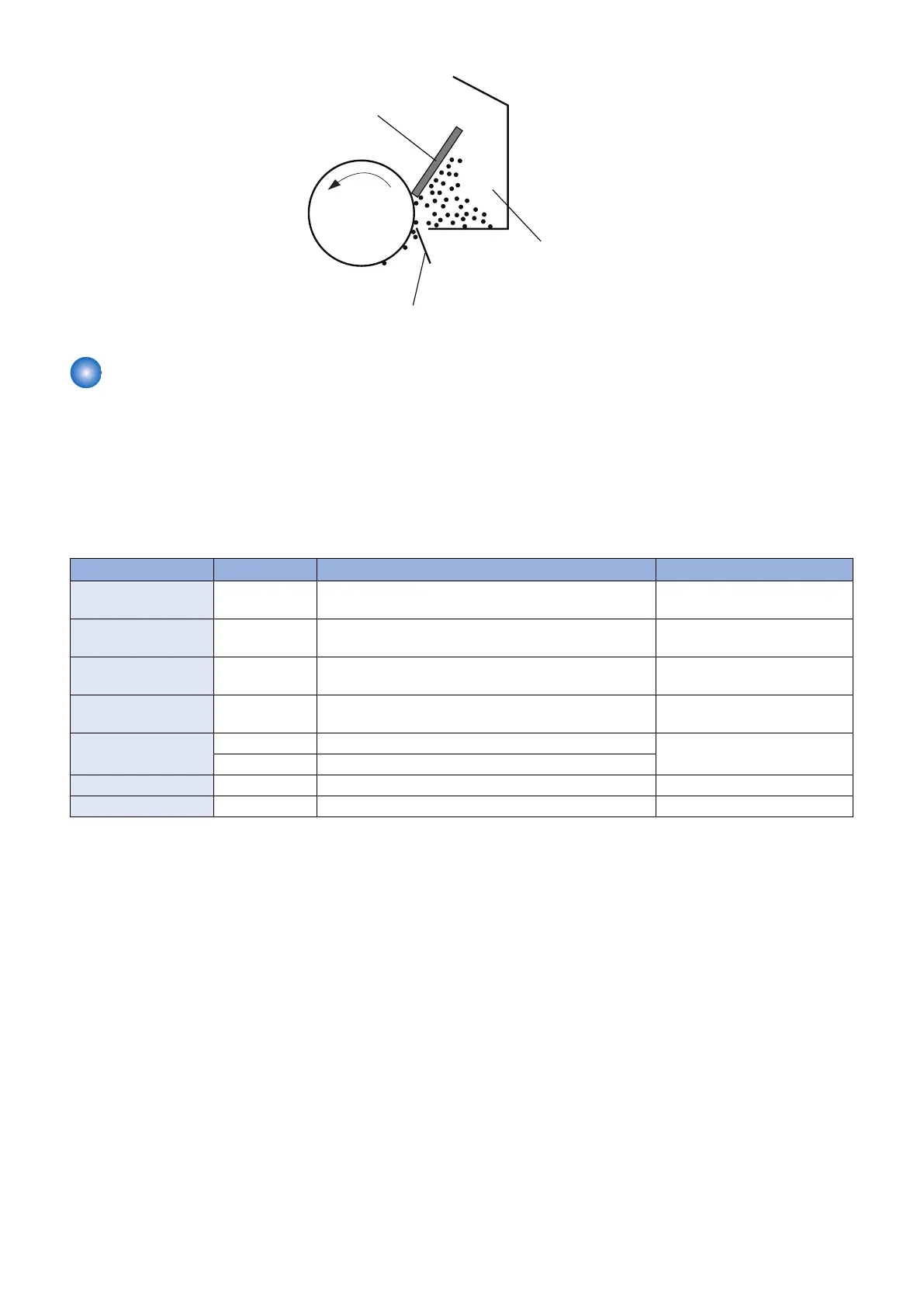

Type Bias applied Purpose Applied to

Primary charging bias DC negative Charge the photosensitive drum surface negatively. Primary charging roller (car-

tridge)

Developing bias DC negative Deposit toner on the static latent image formed on the

photosensitive drum.

Developing cylinder (cartridge)

Blade bias DC negative Adjust the charged toner amount on the developing cylin-

der.

Developing blade (cartridge)

Primary transfer bias DC negative Transfer the toner image on the photosensitive drum to the

ITB.

Developing blade (cartridge)

Secondary transfer bias DC positive Transfer the toner image on the ITB to the paper. Secondary transfer external roll-

er

DC negative Clean the secondary transfer external roller.

ITB cleaning brush bias DC positive Charge the toner on the ITB positively. ITB cleaning brush

ITB cleaning roller bias DC positive Charge the toner on the ITB positively. ITB cleaning roller

2. Technical Explanation

35

Loading...

Loading...