fill tank with diesel fuel.fill tank with diesel fuel.

t level. (Add pre-mixed 50/50t level. (Add pre-mixed 50/50

permanent antifreeze-water as required.)permanent antifreeze-water as required.)

USE MONOPROPYLENE GLYCOL ONLY.USE MONOPROPYLENE GLYCOL ONLY.

connections for leaks. (Tighten connections and/orconnections for leaks. (Tighten connections and/or

replace gaskets.)replace gaskets.)

position (backseat position).position (backseat position).

-belts for prop-belts for prop

, fraying or cracks., fraying or cracks.

Adjust belt or Adjust belt or

Check battery terminaCheck battery termina

ls and electrical connecls and electrical connec

for cleanliness and tightness. Clean and coat with afor cleanliness and tightness. Clean and coat with a

mineral type grease (such as Vaseline).mineral type grease (such as Vaseline).

condition of air cleaner hose.condition of air cleaner hose.

11.Check defrost drain pan hoses. (Should be clear of11.Check defrost drain pan hoses. (Should be clear of

12.Check defrost air switch tubes and connections for12.Check defrost air switch tubes and connections for

breaks or air leaks.breaks or air leaks.

ture. (Should bture. (Should b

Listen for abnListen for abn

ises. (Refer to section 5.3.7ises. (Refer to section 5.3.7

ressor oil levressor oil lev

el (Refer to section 4.10).el (Refer to section 4.10).

y signs of lube or fuel oiy signs of lube or fuel oi

Feel filter-drFeel filter-dr

. Excessive tempe. Excessive tempe

rature drop acrosrature drop acros

drier indicates restriction.drier indicates restriction.

Start microprStart micropr

r Pre-trip Inspecr Pre-trip Inspec

or any other starting aids be used toor any other starting aids be used to

start engine.start engine.

always starts and operates in high speed, unloadedalways starts and operates in high speed, unloaded

microprocessor will prevent operation in high speedmicroprocessor will prevent operation in high speed

until coolant temperature reaches this temperature.until coolant temperature reaches this temperature.

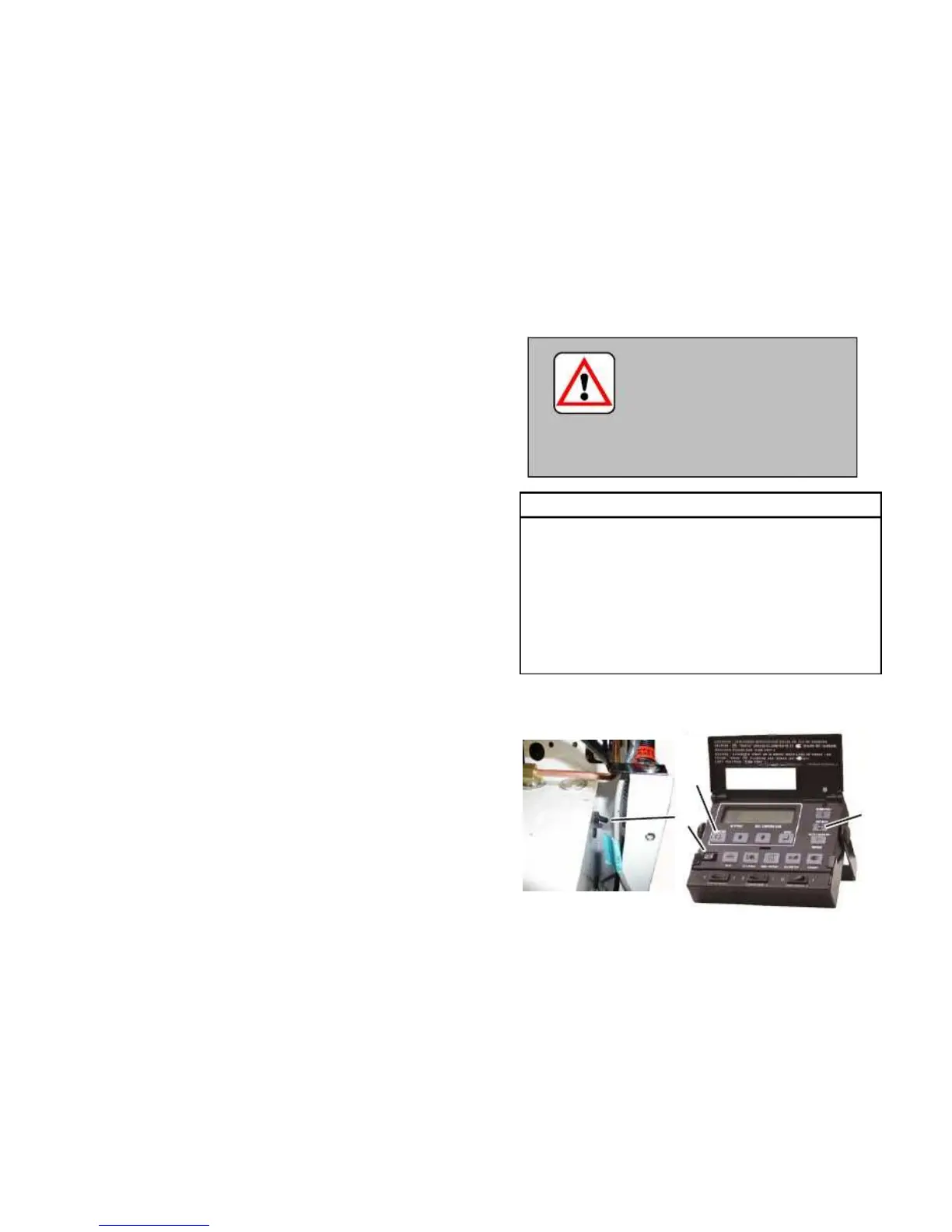

Run-Stop SwitchRun-Stop Switch

in the RUN position onin the RUN position on

the Control Box.the Control Box.

On-Off Switch On-Off Switch

(Cab Command) to ON (Cab Command) to ON

microprocessor will perform a self-test (all displaymicroprocessor will perform a self-test (all display

Loading...

Loading...