RS – Multi-Stage, I-280

Centrifugal Pump 280 – 16.03.EN

4

J. UNAUTHORIZED MODES OF OPERATION. The

warranty relating to operating reliability and safety of the

unit supplied is only valid if the pumping unit is used in

accordance with its designated use as described in the

following sections. The limits stated on the nameplate

must not be exceeded under any circumstances.

K. EXPLOSION PROTECTION. If the pumps/units are

installed in potentially explosive atmospheres, the

measures and instructions given in the following

sections K.1 to K.6 must be adhered to without fail, to

ensure explosion protection.

K.1 Unit Fill.

It is assumed that the system of suction

and discharge lines and thus the wetted pump

internals are completely filled with the fluid to

be handled at all times during pump operation,

so that an explosive atmosphere is prevented.

If the operator cannot warrant this

condition, appropriate monitoring devices must

be used.

CAUTION

In addition, it is imperative to make sure that

the seal chambers, auxiliary systems of the

shaft seal and the heating and cooling systems

are properly filled.

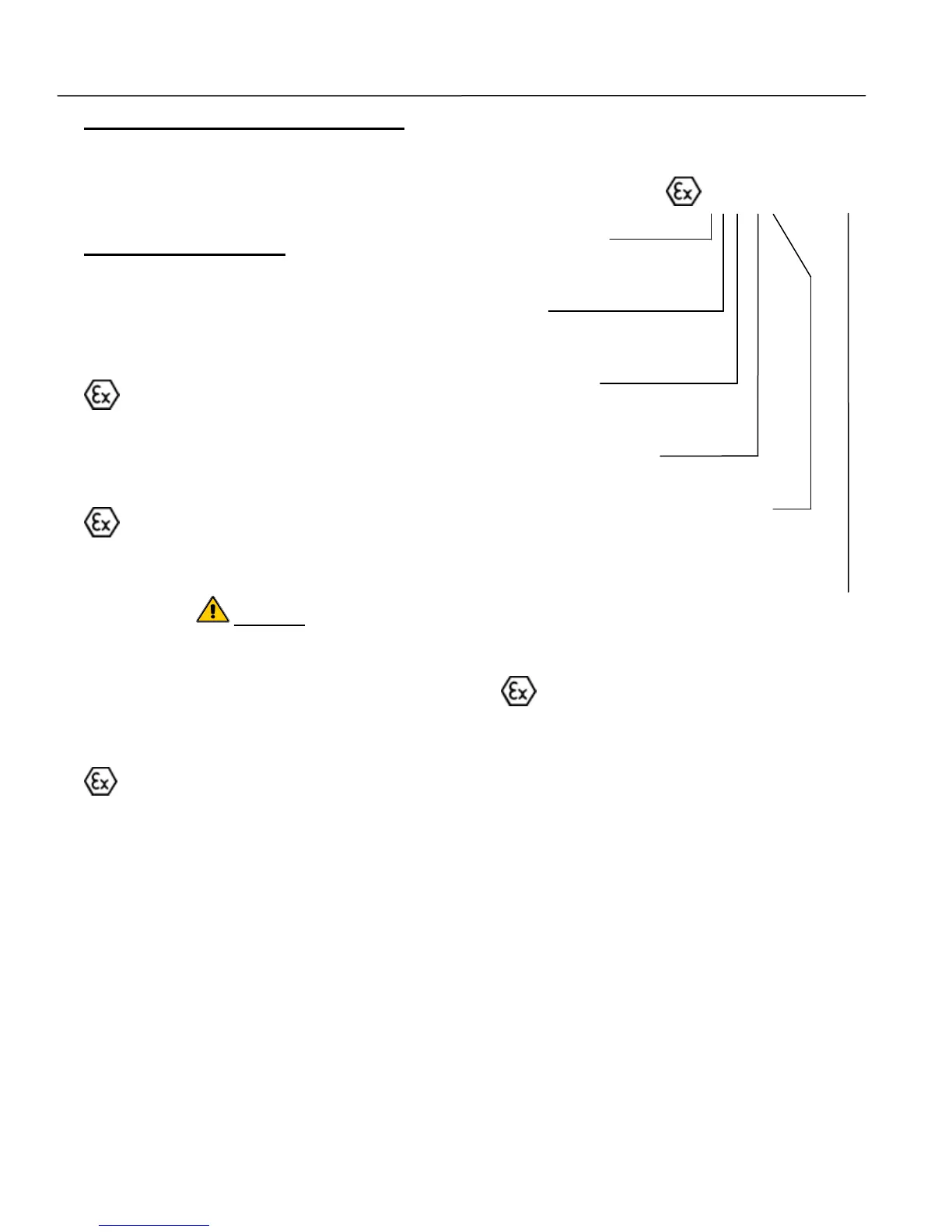

K.2 Marking.

The marking on the pump only refers to

the pump, i.e. the coupling and driver must be

regarded separately. The coupling must have

an EC manufacturer’s declaration. The driver

must be regarded separately.

An example of ATEX equipment marking is shown

below. The actual classification of the pump will be

engraved on the nameplate.

II 2 GD c IIC 135 ºC (T4)

Equipment Group

I = Mining

II = Non-mining

Category

2 or M2 = high level protection

3 = normal level of protection

Gas and/or dust

G = Gas

D = Dust

c = Constructional safety

(in accordance with EN13463-5)

Gas Group (Equipment Category 2 only)

IIA – Propane (typical)

IIB – Ethylene (typical)

IIC – Hydrogen (typical)

Maximum surface temperature (Temperature Class)

(Refer to Section II, Paragraph K.5)

K.3 Checking the Direction of Rotation.

If the explosion hazard also exists during

the installation phase, the direction of rotation

must never be checked by starting up the

unfilled pump unit, even for a short period, to

prevent temperature increases resulting from

contact between rotating and stationary

components.

K.4 Pump Operating Mode.

Make sure that the pump is always started up with the

suction-side shut-off valve fully open and the discharge-

side shut-off valve slightly open. However, the pump can

also be started up against a closed swing check valve.

The discharge-side shut-off valve shall be adjusted to

comply with the duty point immediately following the run-

up process.

Loading...

Loading...