RS – Multi-Stage, I-280

Centrifugal Pump 280 – 16.03.EN

38

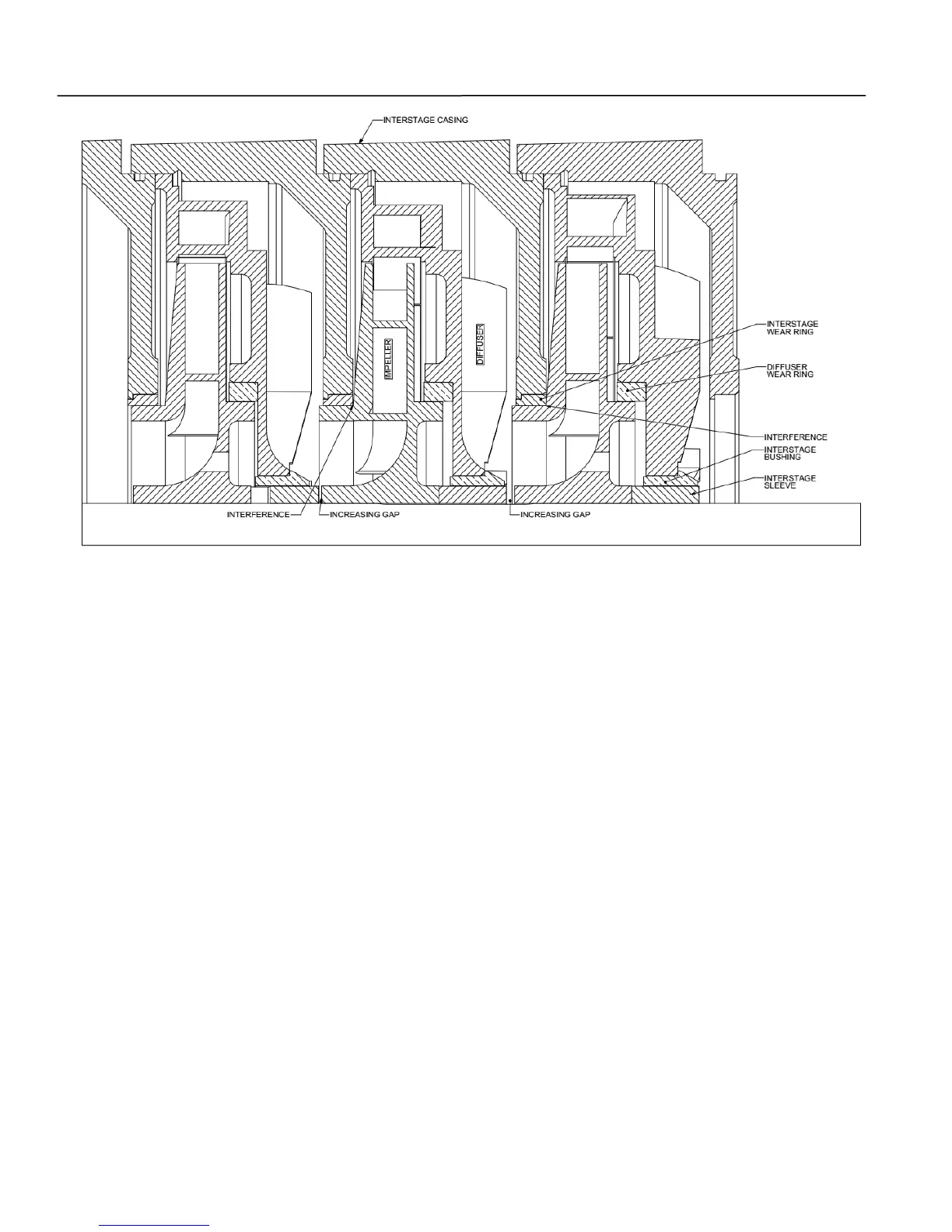

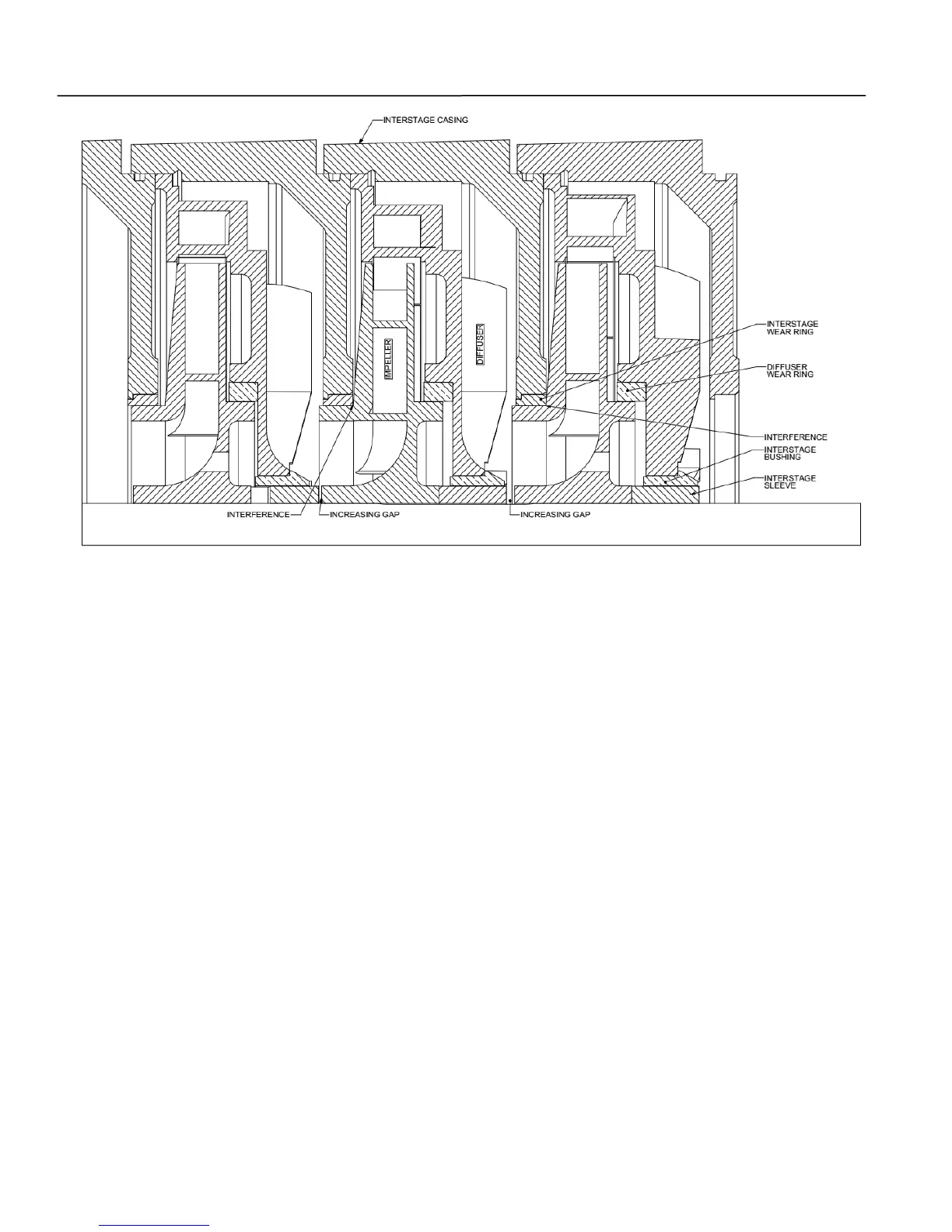

Figure 11. Bushing Not Torqued Interference

24. Remove interfering stages keeping close track

of how many shims are between each stage.

25. Slide outboard sleeve (14X) onto outboard end

of shaft (6), aligning keyway in sleeve with

impeller key (32).

26. Install O-ring (89A) onto last stage diffuser

bushing (63X). Install last stage diffuser bushing

into last stage diffuser (5X), make sure that

diffuser wear ring (7X) is installed in the last

stage diffuser.

NOTE

Refer to Table 5, Sleeve Bearing Dimensions to

determine if replacement of sleeve bearing

(63Y) is required.

27. Install the last stage diffuser (5X) with last stage

diffuser bushing (63X) and bushing O-ring (89A)

into the discharge case (1). Install sleeve

bearing (63Y) in discharge casing (1).

28. Install the discharge casing (1) with diffuser

(5X), and wear ring (7X) on interstage casing

(111). Confirm proper discharge casing

orientation.

29. Install tie bolts (173), washers (645) and hex

nuts (616) and torque to 50 ft/lbs temporarily.

NOTE

Remove pump from vertical position and place

in horizontal position either on a milled flat

surface or a pump base.

30. Loosen the tie bolt hex nuts (616) and tap with

soft mallet both suction and discharge casings

to make feet flat to the milled surface of the

base.

NOTE

Ensure that the pump feet are on a milled flat

surface or the base before tie rod hex nuts are

torqued.

31. Tighten hex nuts (616) firmly and evenly. Refer

to Table 14 for recommended torque

requirements.

32. Sleeve (14X) should protrude .09 inch past the

sleeve bearing (63Y), use shims to achieve gap.

33. Install shaft washer (28) on shaft (6).

Loading...

Loading...