RS – Multi-Stage, I-280

Centrifugal Pump 280 – 16.03.EN

20

F. COUPLING ALIGNMENT. The pump and motor

are connected by a coupling. Alignment is necessary

when the pump or motor are removed from the base.

The coupling should NOT be reconnected until the

alignment has been completed. Always check the

coupling alignment after shipping. The following is how

to check the coupling alignment.

NOTE

Refer to coupling manufacturer’s manual for

instructions regarding shaft alignment and

recommended installation limits.

Soft Foot – The equipment must rest flat on its

base. If one or more feet of the pump or motor

are shorter, longer, or angled in some way to

prevent uniform contact (a condition commonly

known as “soft foot”) it must now be corrected.

To improve the life of the coupling, the shafts must be

aligned to minimize deflection of the flexing elements.

Shaft alignment is required in the axial, parallel, and

angular directions, with each of these values not to

exceed the recommended installation limits. Shaft

alignment can be measured using various established

methods, including Laser Alignment, Reverse Dial

Indicator, and Rim and Face.

The motor and pump shafts must be accurately aligned

as any misalignment can cause damage to the coupling,

motor, or pump. When the shafts are in correct

alignment, the coupling hubs will be on a common axis,

concentric with each other, and at the correct distance

apart. If the coupling hubs are misaligned, it is general

practice to adjust the driver to the pump. Insert full

shims under the feet or supports of the motor and

tighten fastening bolts until correct alignment is

achieved.

1. Move the pump or motor to achieve acceptable

alignment. When properly aligned, the disc

packs will be centered and approximately

parallel to their mating flange faces and the

flexing elements will have little visible waviness

when viewed from the side.

NOTE

Refer to the coupling manufacturer’s manual for

recommended installation limits for Parallel,

Angular, and Axial alignment.

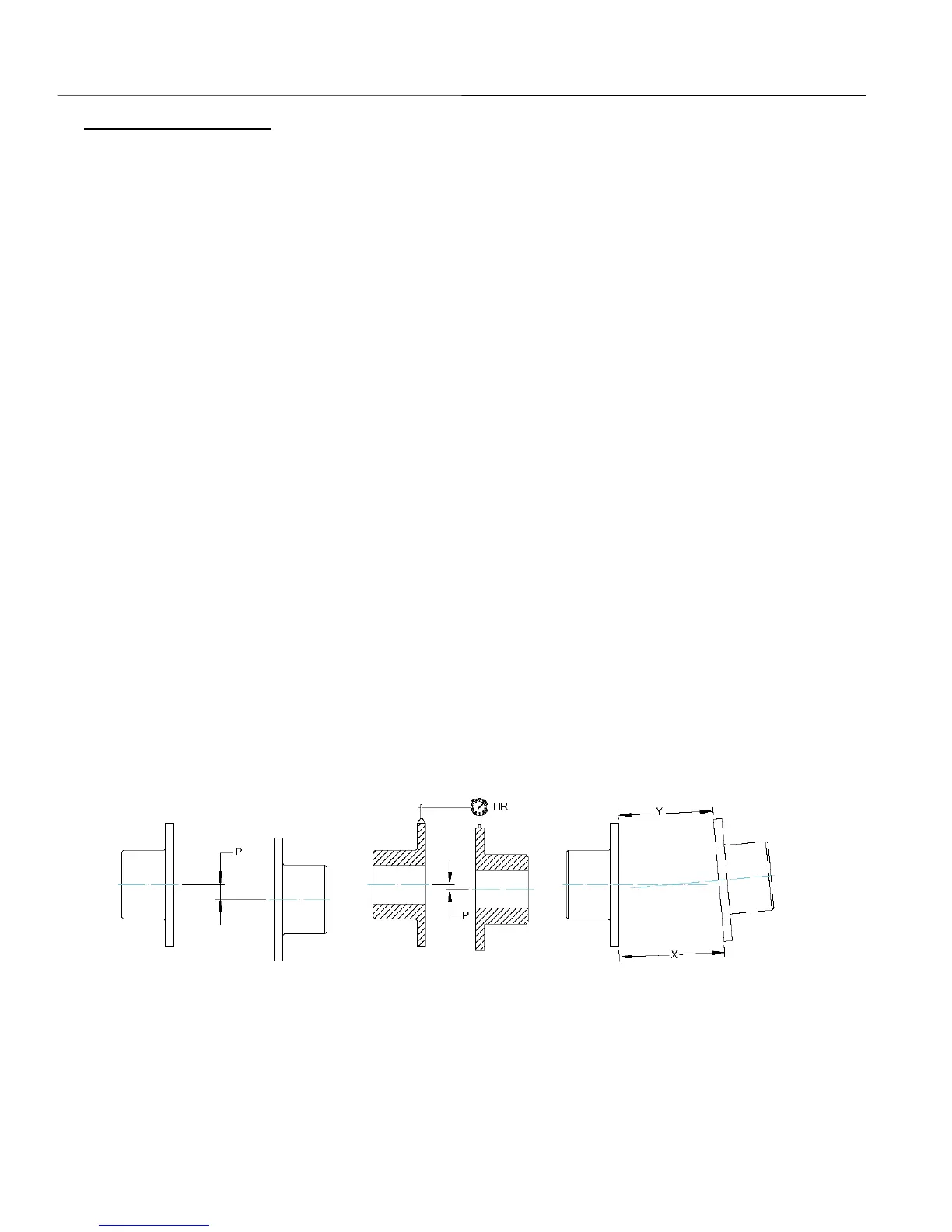

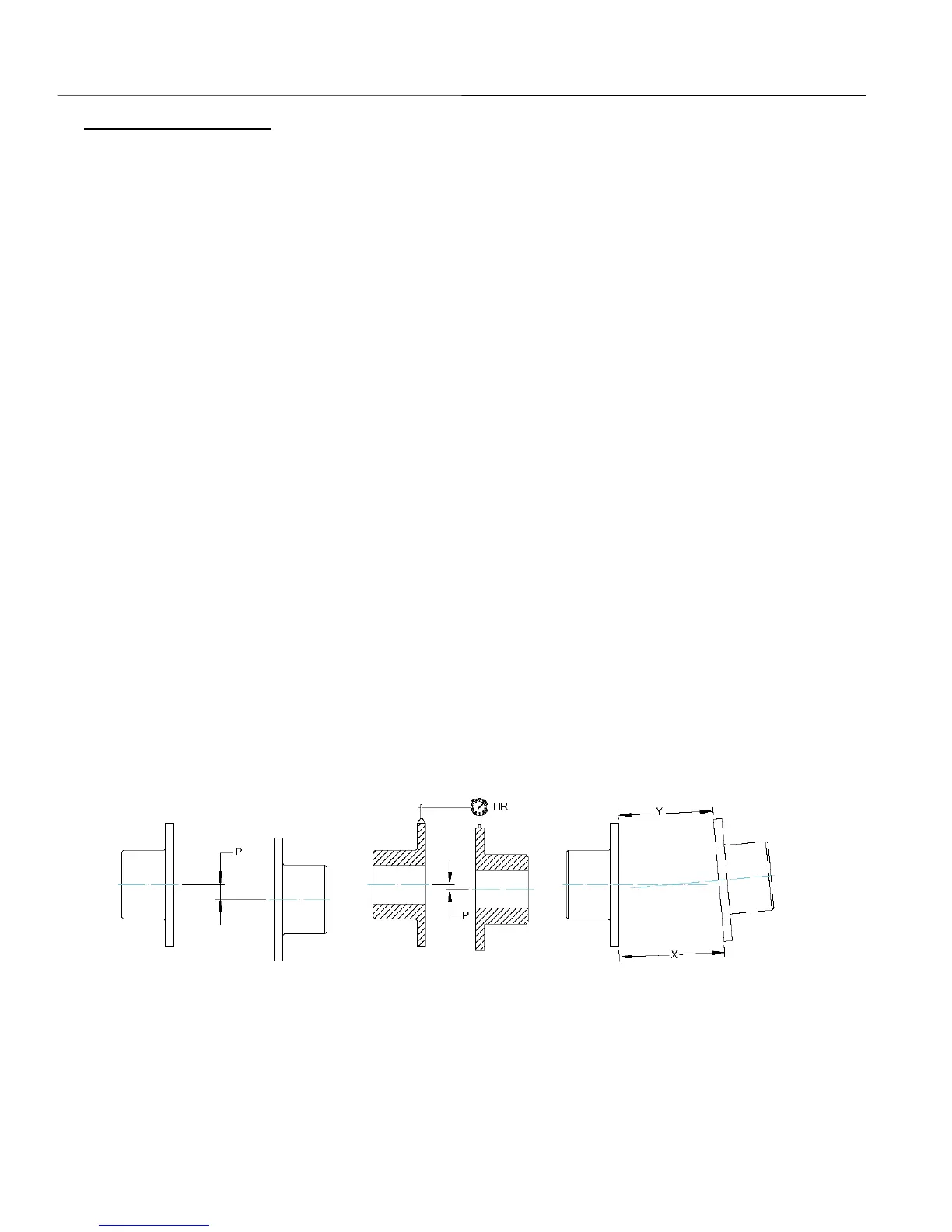

2. The “Parallel Misalignment” value (P) is the

offset between the centers of the hubs, as

shown in Figure 9.

3. When the Parallel Offset is measured by

rotating the hubs in unison with dial indicators

as shown in Figure 9, the Total Indicator

Reading (TIR) should be divided by (2) to

calculate (P).

4. It should be noted that parallel offset measured

on the hub surfaces includes misalignment of

the equipment shafting plus any variation (TIR)

in the hubs. This may be helpful to consider

during problem solving for alignment difficulties.

5. The “Angular Misalignment” value is the

maximum difference between the

measurements X and Y taken at opposite ends

of the hub flanges, as shown in Figure 9.

Figure 9. Coupling Alignment

Parallel Offset Misalignment

Parallel Offset (TIR)

Measurement

Loading...

Loading...