RS – Multi-Stage, I-280

Centrifugal Pump 280 – 16.03.EN

27

the bearing frame (99) with oil (refer to Table 12 for oil

recommendations) through the breather vent (405) until

oil can be seen in the center of the oil view sight (143)*.

Table 12. Oil Recommendations

Table 13. Bearing Cooling Flow Rates

(30 PSIG MAX.)

-20˚ to 225˚ F

(-4° to 107° C)

225˚ to 285° F

(107° to 140° C)

Oil-Lube – Water

1 Gallons per Minute (GPM)

285˚ to 300° F

(140° to 148° C)

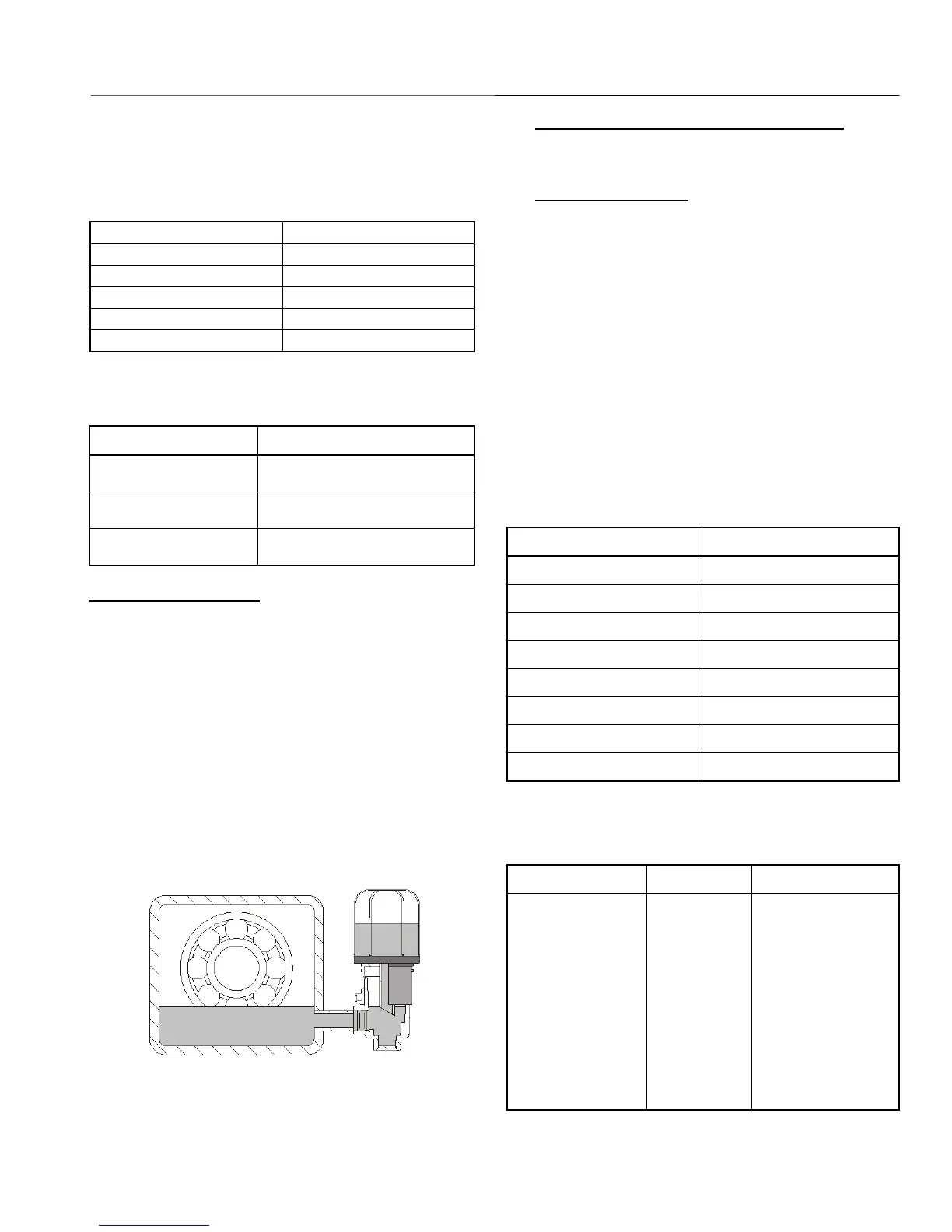

*Constant Level Oiler. If equipped with a constant

level oiler, fill reservoir with oil, place thumb over spout,

invert and screw reservoir into upper casting. Allow

reservoir to empty, filling the bearing frame (Figure 10).

Several fillings of the reservoir may be required before

the actual oil level is reached. To avoid adding too much

oil, never finish filling oil in bearing frame (99) through

the vent breather (405) at top of the bearing frame.

Never use lower casting only as a fill spout, always fill

thru reservoir. When oil level is reached, no more oil will

run out of the reservoir bottle. Use constant level oiler's

glass sight to check oil level in bearing frame. When oil

level is reached tighten the three setscrews on the side

of the upper oiler. The constant level oiler (143) should

be topped up as required during operation.

Figure 10. Constant Level Oiler

B. LUBRICATION OF MOTOR BEARINGS. See

motor manufacturer’s instructions to be sure motor

bearings are properly lubricated.

C. TORQUE VALUES. Refer to Table 14,

Recommended Torque Values. Clean and properly

lubricate threads and bearing face of the fastener to

obtain the proper fastener loading from these torque

values. Fasteners should be tightened evenly and in

stages with a criss-cross bolt pattern. Refer to your

torque wrench manual for the proper use of your

wrench.

Refer to the pump nameplate to determine your pump

model for tie rod torques.

The first bearing jam nut (22) is to have 20 ft-lbs torque

while holding the coupling end of the shaft. The second

bearing jam nut is to be tightened to 30 ft-lbs while

holding the coupling end. Loctite the second bearing jam

nut.

Table 14. Recommended Torque Values (ft-lbs)

315 / 50 ft-lbs increments

446 / 50 ft-lbs increments

*(Refer to Section X, Paragraph C)

Table 15. Recommended Equipment

Spanner Wrench

Rawhide or

Wood Mallet

Coupling

Alignment

Gauges

Socket, Open, &

Box Wrench

Set

Loading...

Loading...