RS – Multi-Stage, I-280

Centrifugal Pump 280 – 16.03.EN

42

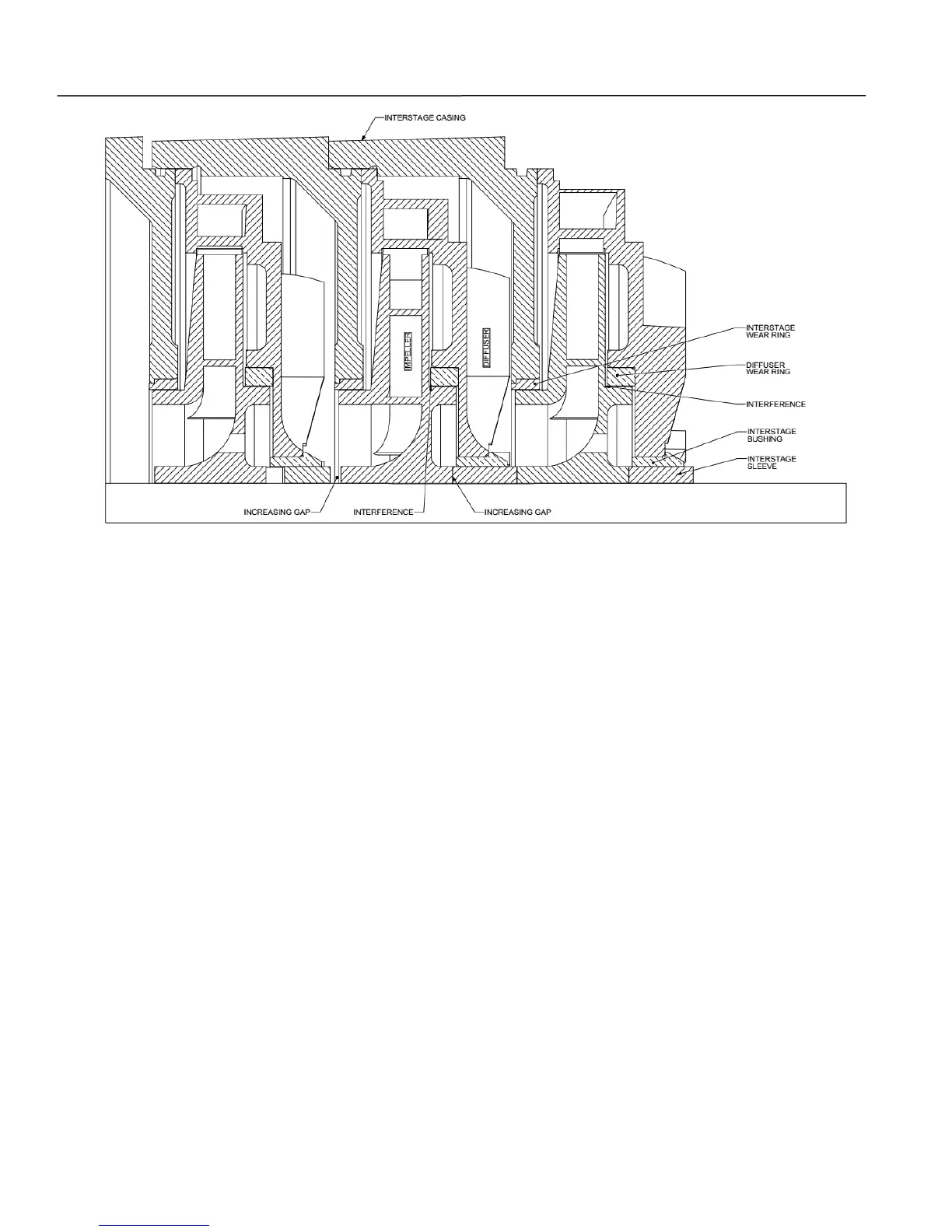

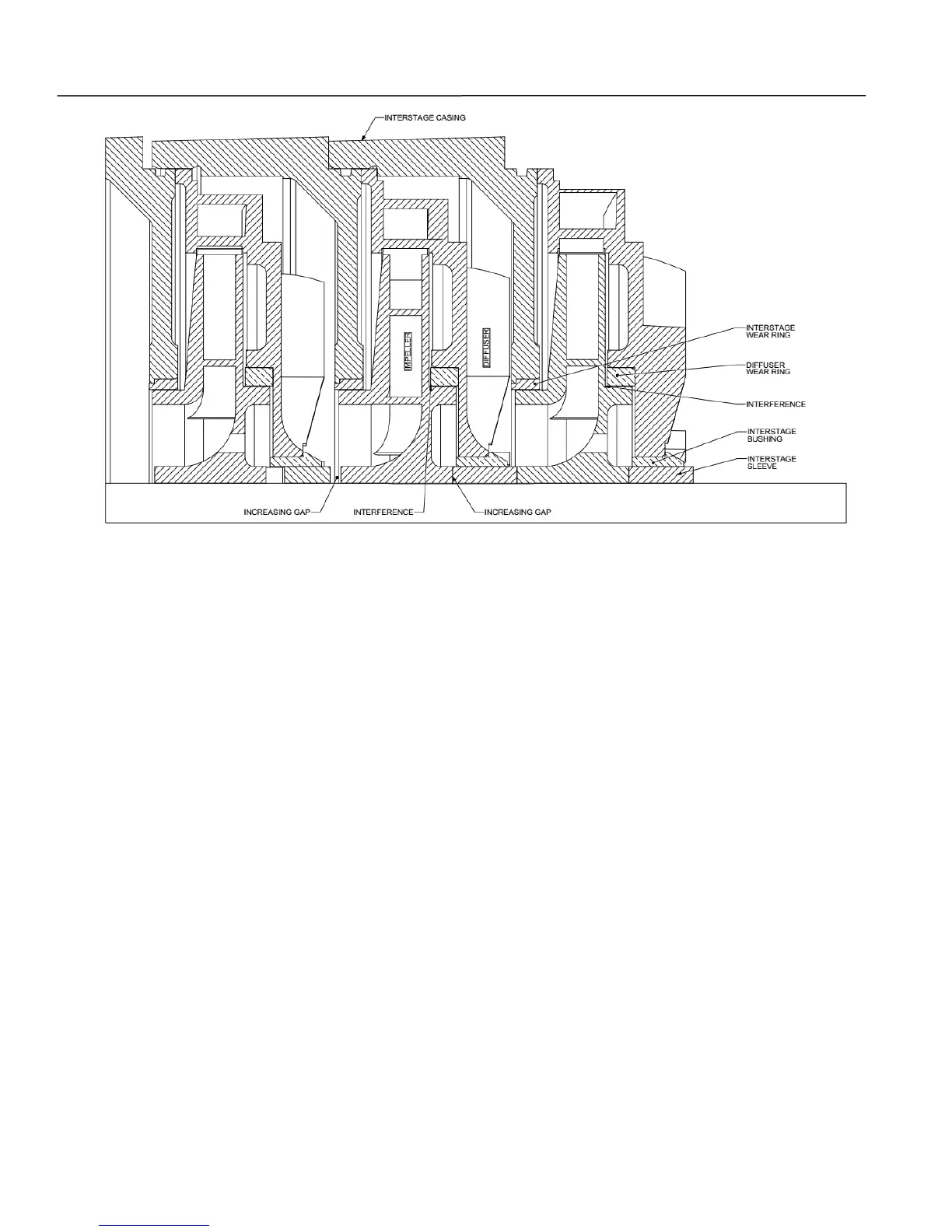

Figure 12. Mechanical Seal Not Torqued Interference

NOTE

Every gap that is left in the stack-up to achieve

that stage final axial impeller alignment will

compound to every stage after it and will have

to be subtracted from all final axial impeller

alignments.

23. Install spacer sleeve (14D) onto shaft (6).

24. Install key (32X) into keyway on shaft (6).

25. Mark shaft (6) and end of sleeve (14A) to

determine location of key aligning key to

keyway.

26. Lubricate and install sleeve O-ring (89X) and

slide into groove on shaft (6).

27. Install sleeve (14A) onto shaft (6).

28. Lubricate and install casing O-ring (89D) onto

suction casing (9).

29. Install suction casing (9) and tap into place

against interstage casing (111), insure proper

flange orientation of suction casing. Confirm

gland studs (630) are installed in suction casing.

30. Install tie bolts (173), flat washers (645) and tie

bolt hex nuts (616) and temporarily torque hex

nuts to 50 ft/lbs.

31. Install spacer sleeve (14G). Install bearing

frame (99) on suction casing (9) temporarily with

two bolts (600). Install bearing (16) and install

one jam nut (22), leave loose.

NOTE

Remove pump from vertical position and place

in horizontal position either on a milled flat

surface or a pump base.

32. Loosen the tie bolt hex nuts (616) and tap with

soft mallet both suction and discharge casing

feet flat to the milled surface or the base.

NOTE

Ensure that the pump feet are on a milled flat

surface or the base before tie rod hex nuts are

torqued.

33. Tighten tie bolt hex nuts (616) firmly and evenly.

Refer to Table 14 for recommended torque

requirements.

Loading...

Loading...