RS – Multi-Stage, I-280

Centrifugal Pump 280 – 16.03.EN

37

Example – With Standard Sleeve Bearing

– RS9-A stage 11 Axial Impeller Alignment setting = .742”

Impeller without sleeve = .760” / With sleeve = .760” – No change

Add two shims = .020” – Measurement now at .765” – meaning .015” Gap between impeller and sleeve

Remove one shim = .010” – Measurement now at .760” minus the .005” Gap and minus the .005 Gap from

stage 10 gives a Final = .750” Axial Impeller Alignment setting for stage 11 = Good due to +/- .010”

tolerance.

Example – With Optional Mechanical Seal

RS9-A stage 15 Axial Impeller Alignment setting = (-.152”)

Impeller without sleeve = (-.135”) / With sleeve = (-.135”) – No change

Add two shims = .020” – Measurement now at (-.130”) – meaning .015” Gap between impeller and sleeve

Remove one shim = .010” – Measurement now at (-.135”) minus the .005” Gap and minus the .005 Gap

from stage 14 gives me a Final = (-.145”) Axial Impeller Alignment setting for stage 15 = Good due to +/-

.010” tolerance.

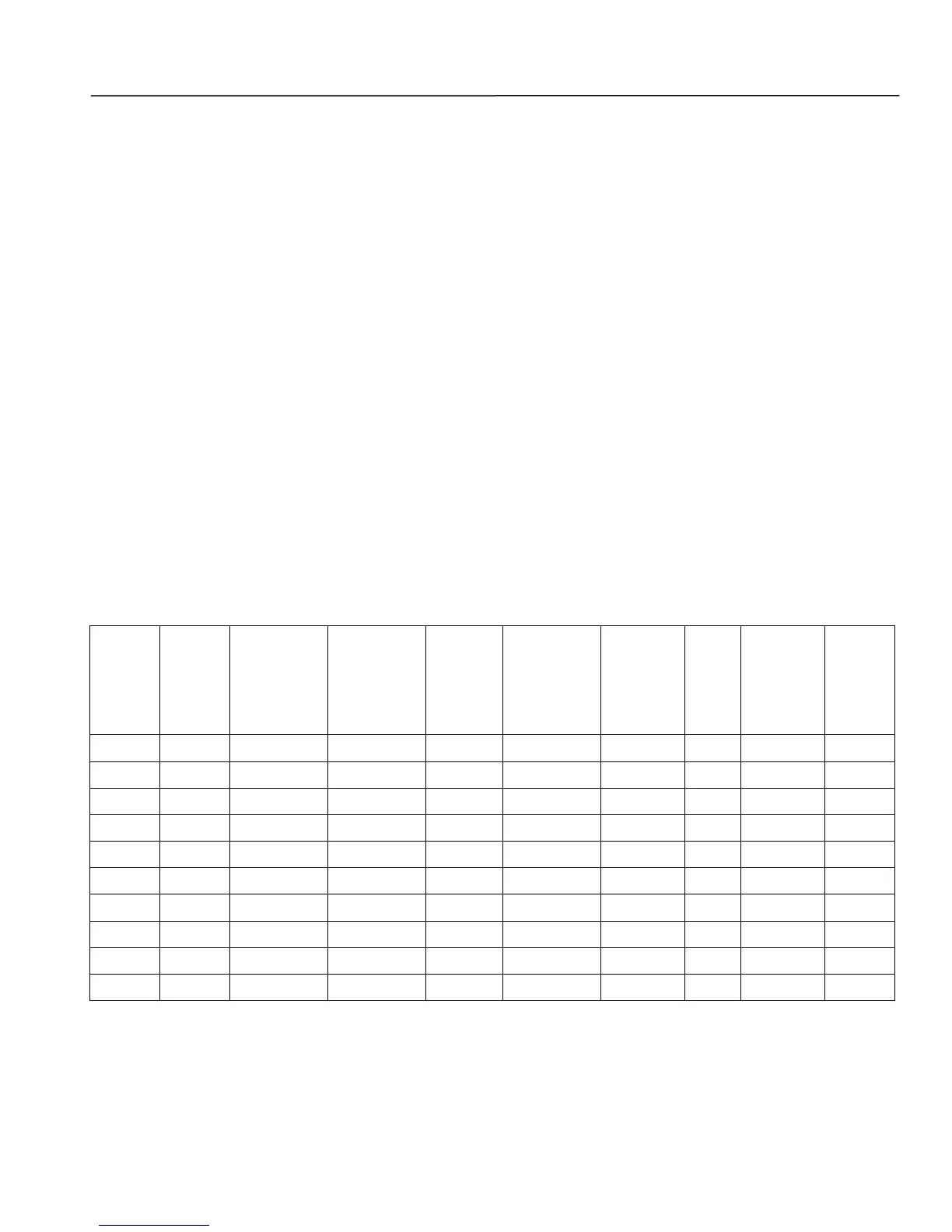

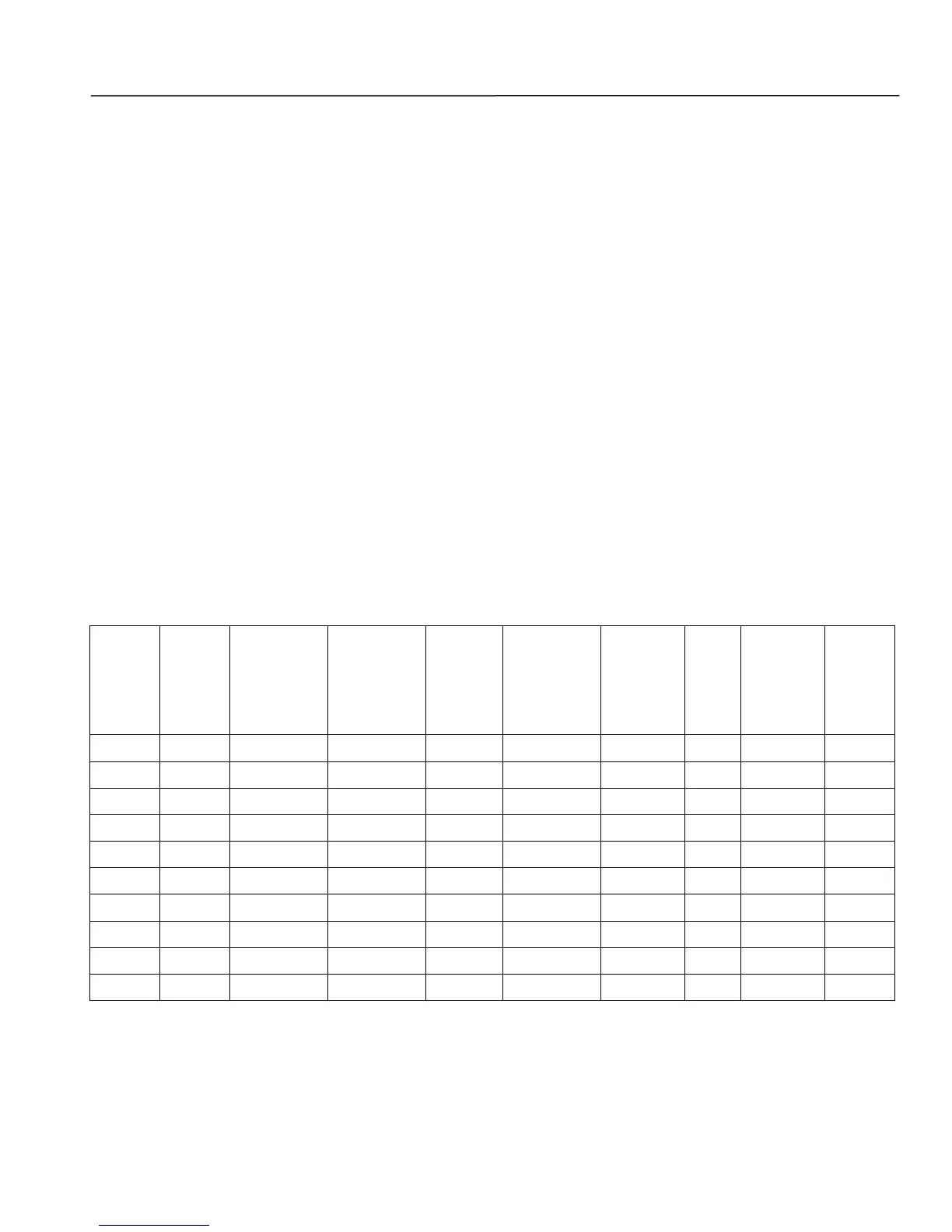

Table 17. Axial Alignment Worksheet

Table 3.

Axial

Impeller

Setting

Impeller with

NO Sleeve

Measurement

Impeller

WITH Sleeve

Measurement

Number

of (.010”)

Shims to

Lift

Impeller

Axial Impeller

Alignment

Measurement

#2

Number of

Shims Left

out to

Achieve

Table 3

Setting

Final Axial

Impeller

Alignment

Setting

Loading...

Loading...