RS – Multi-Stage, I-280

Centrifugal Pump 280 – 16.03.EN

25

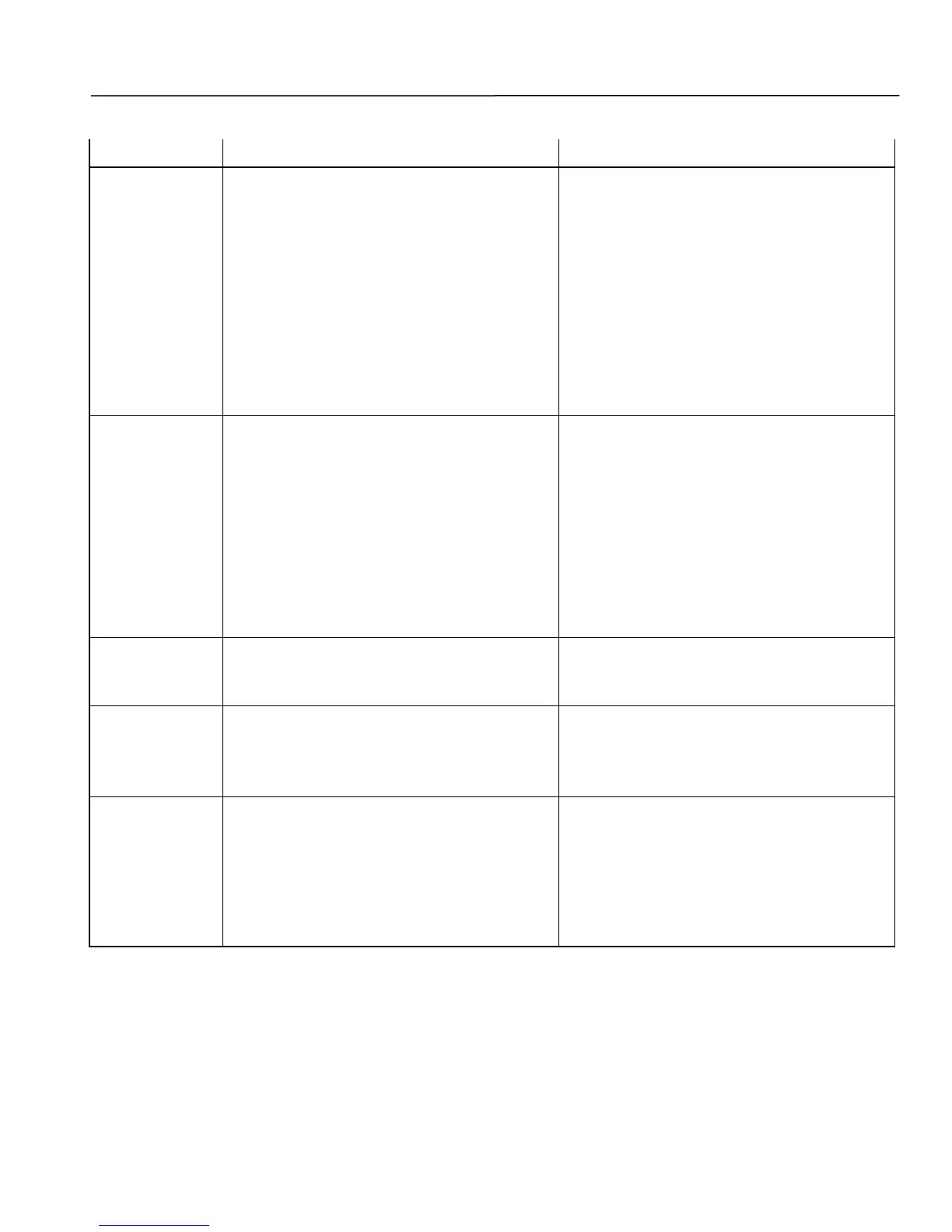

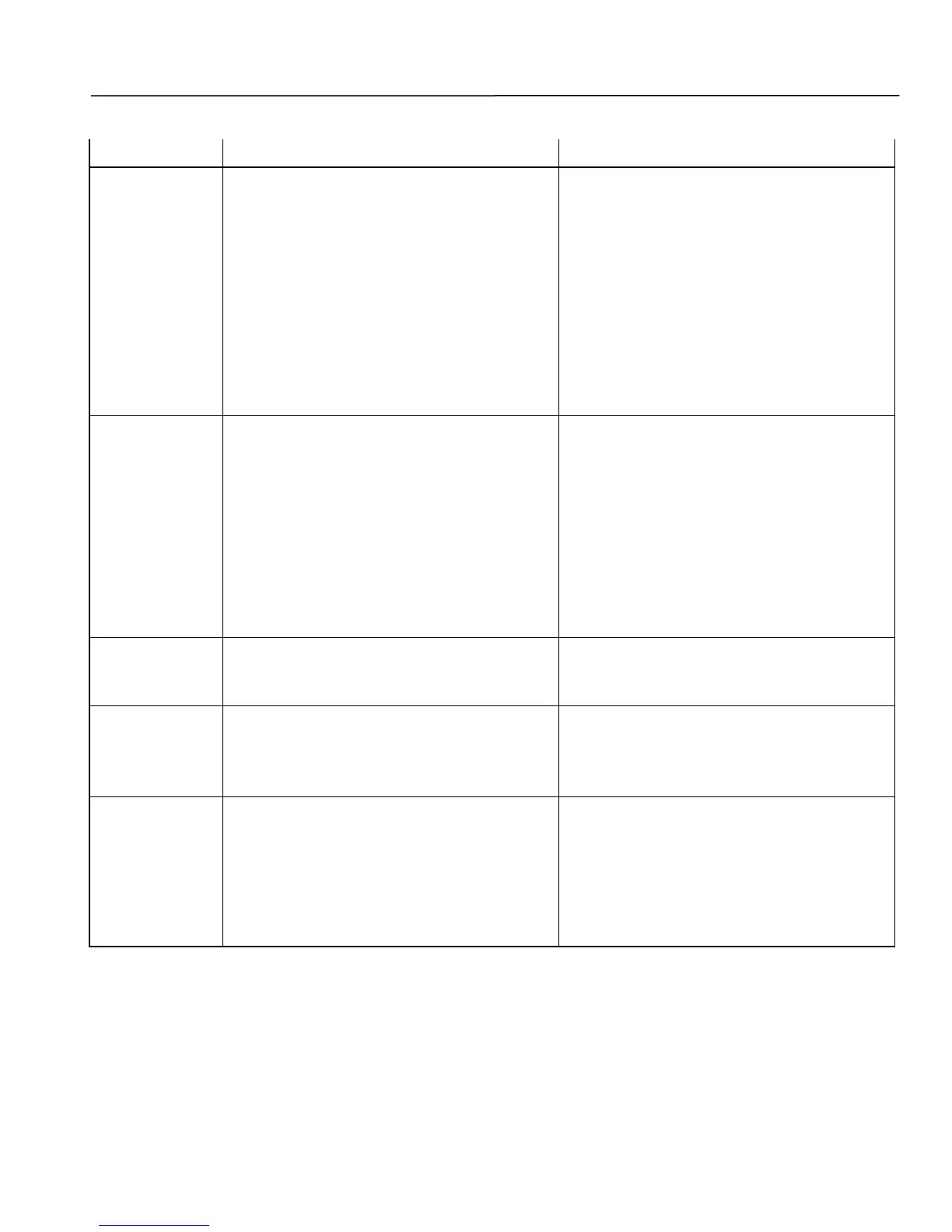

Table 11. Pumping Unit Troubleshooting - Continued

Insufficient

discharge or

flow.

1. Discharge head above shutoff.

2. Air or gases in liquid.

3. Impeller or suction partially clogged.

4. Wrong direction of rotation.

5. Specific gravity or viscosity of liquid is too

high.

6. Incorrect impeller diameter.

1. Check pump rating against actual head

condition.

2. Adjust and/or redesign suction system. Add

liquid to system.

3. Inspect suction and impeller and clean as

necessary.

4. Reverse direction of rotation.

5. Check liquid temperature and adjust as

necessary.

6. Replace impeller or trim impeller to correct

diameter. Consult with Carver Pump before

trimming impeller.

1. Foundation bolting loose.

2. Coupling halves not properly oriented

relative to each other.

3. Impeller partially blocked.

4. Wrong rotation.

5. Insufficient foundation.

6. Pipe strain.

7. Coupling key to motor or coupling key to

pump is not correct length.

8. Motor improperly balanced.

1. Torque bolting to proper values.

2. Adjust coupling halves system relative to

match marks.

3. Inspect impeller and clean as necessary.

4. Adjust direction of rotation.

5. Stiffen foundation as necessary.

6. Modify piping as necessary.

7. Replace with key of correct length.

8. Balance motor.

Leakage at

casing joints.

1. Tie bolts not sufficiently tightened.

2. O-rings damaged.

1. Release the pressure and tighten the tie

bolts.

2. Replace O-rings.

1. Loose connection.

2. Defective oil seal.

3. Loose or defective gasket.

1. Tighten connectors.

2. Replace oil seal.

3. Tighten bolting and/or replace gasket.

Bearing

temperature

excessive.

1. Lubrication, insufficient lubrication.

2. Defective ball bearing.

3. Pump/driver shafts are misaligned.

4. Piping causes pump to “warp”.

1. Lubricate according to Section X,

Paragraph A.

2. Replace ball bearing.

3. Check coupling alignment.

4. Ensure piping transmits no stress to pump.

Alter piping layout, if necessary. Realign

pump and driver shafts.

Loading...

Loading...