Before Installation

IM-ChipEncoder-Series-Rev. 2 Page 5 ©2022 Celera Motion

ChipEncoder Series

Installation Manual and Reference Guide

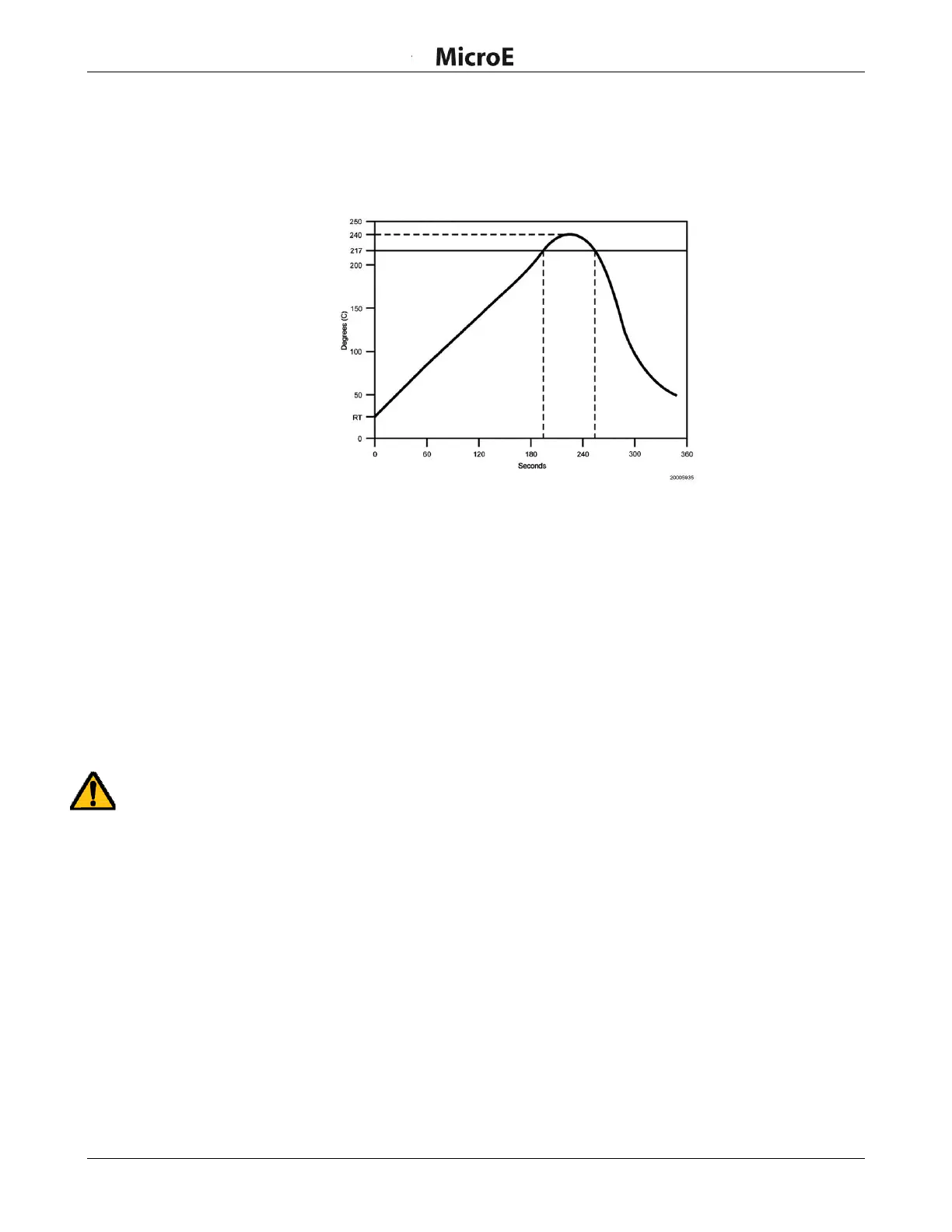

2.4 Solder Paste Recommendation and Reflow Profile

The ChipEncoder can be soldered to a PCB using industry standard techniques. The diagram below

illustrates the recommended reflow temperature profile.

Lead-Free Solder Reflow

Use a temperature-controlled convection or IR reflow oven and SAC305 solder paste with no-clean flux

in either air or an inert atmosphere (N

2

). The temperature should be measured on the carrier board close

to the ChipEncoder parts and should not exceed 260°C.

The ChipEncoder has soldered devices under the cover. The rate of heating and cooling must be

controlled so that it does not exceed 5°C per second to avoid thermal stressing of the devices.

The ChipEncoder inputs and outputs are pre-tinned palladium silver pads with the typical spacing

between adjacent input/output pads of 0.2 mm (0.008 inches). The pads are pre-tinned with SAC305

solder alloy. Solder material with good slump characteristics should be chosen to ensure that solder

does not bridge or short during pre-heating in the reflow process.

Hand Soldering

Hand soldering can cause damage. Hand soldering guidelines:

CE300: Do not hand solder. Castellations are for electrical testing only.

CE: Hand solder only if necessary.

Reflow Solder

Temperature Profile

Loading...

Loading...