33Method - Create, Edit and Delete

NOTE

Moisture/Fat and Moisture/Fat/Protein methods require the use of a CEM Fat analyzer. For details on

creating this type of method, please refer to the Operation Manual for the corresponding Fat analyzer.

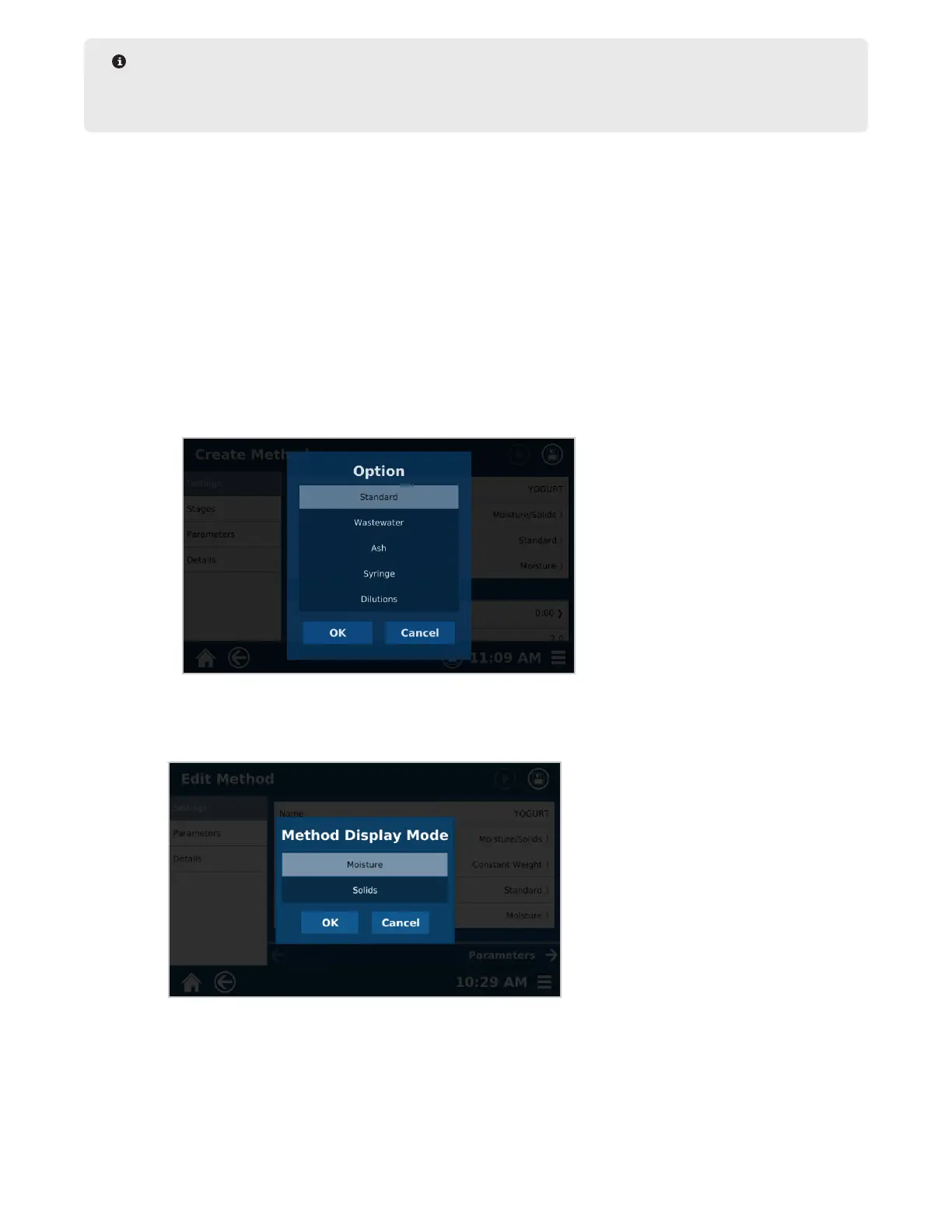

3.3. Choose the option that best analyzes the sample.

• Standard – Loss on Drying (LOD) analysis testing for Moisture, Solids, or Volatile content only.

Calculates the difference between initial weight and nal weight

• Waste Water –Total Suspended Solids or Total Volatile Suspended Solids. Typically utilizes a ltration

step along with the LOD analysis on the SMART 6

• Ash – The LOD step is followed by placing the sample into an ashing furnace, then returning the

sample to the SMART 6 for a nal weight measurement.

• Syringe – When rapid evaporation makes obtaining a stable initial weight difcult, the syringe method

can be used instead of directly weighing the amount of sample on the sample pad. The sample is

pulled into a syringe. The syringe is weighed before and after adding the sample to the sample pad,

and the weight difference in the syringe is used as the initial weight.

• Dilution – The sample is diluted and the dilution factor is calculated into the nal results as a

dilution factor. This analysis requires an external balance connected to the SMART 6.

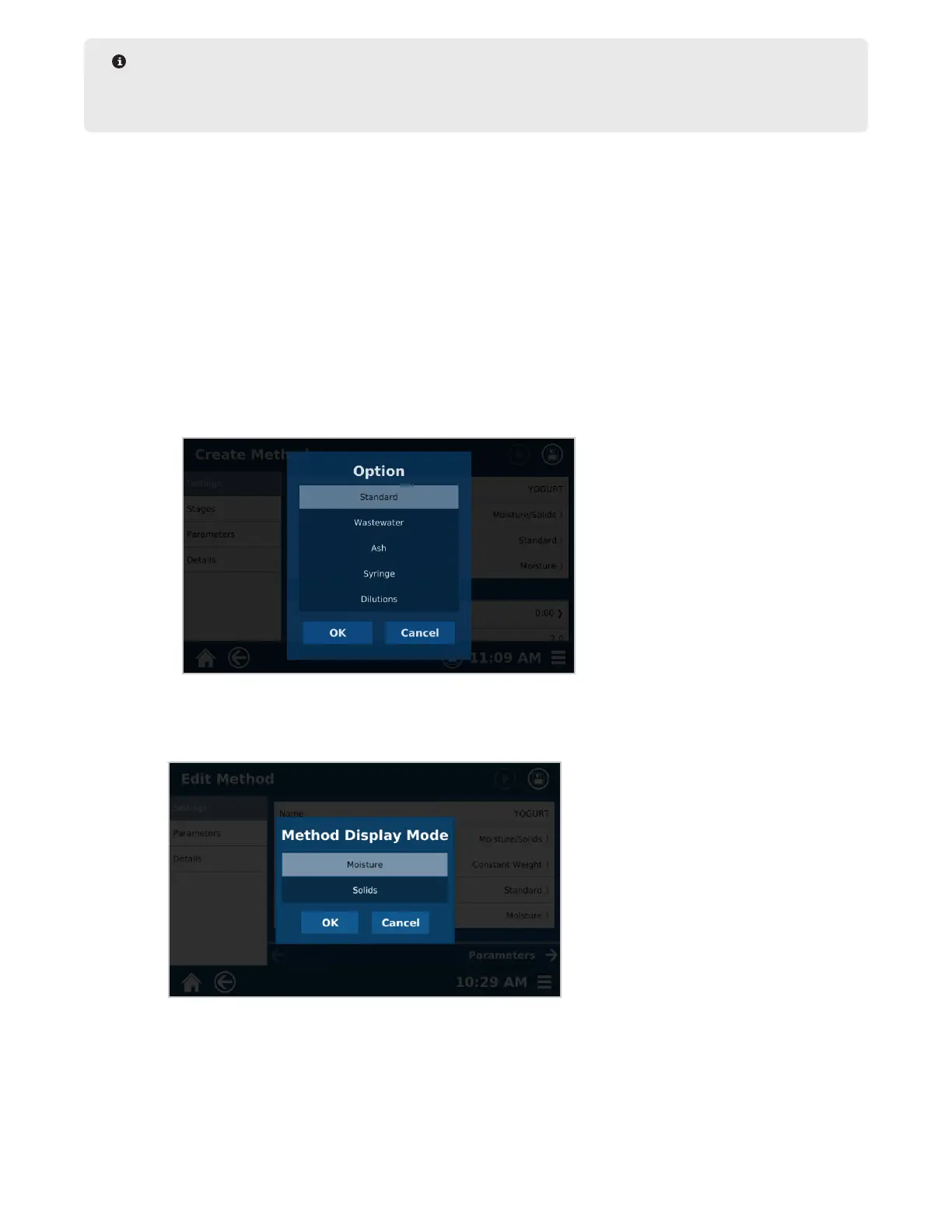

3.4. Designate the desired unit of measurement (Moisture or Solids) by toggling Calculation Mode. This

measurement will be the value displayed rst in databases and printouts, but both moisture and solid

values can be accessed for any sample.

3.5. Set the Category eld based on the sample type and desired analysis

• Ramp Time – The amount of time specied to ramp up to temperature at the beginning of the stage.

• Ramp Temperature – the beginning temperature when ramping occurs. Ramping will continue until

the maximum temperature is reached.

Loading...

Loading...