chapter 5000

page 6

1,2 - 2,0 t A.C.

SERVICE MANUAL

Electric

036-0410-07

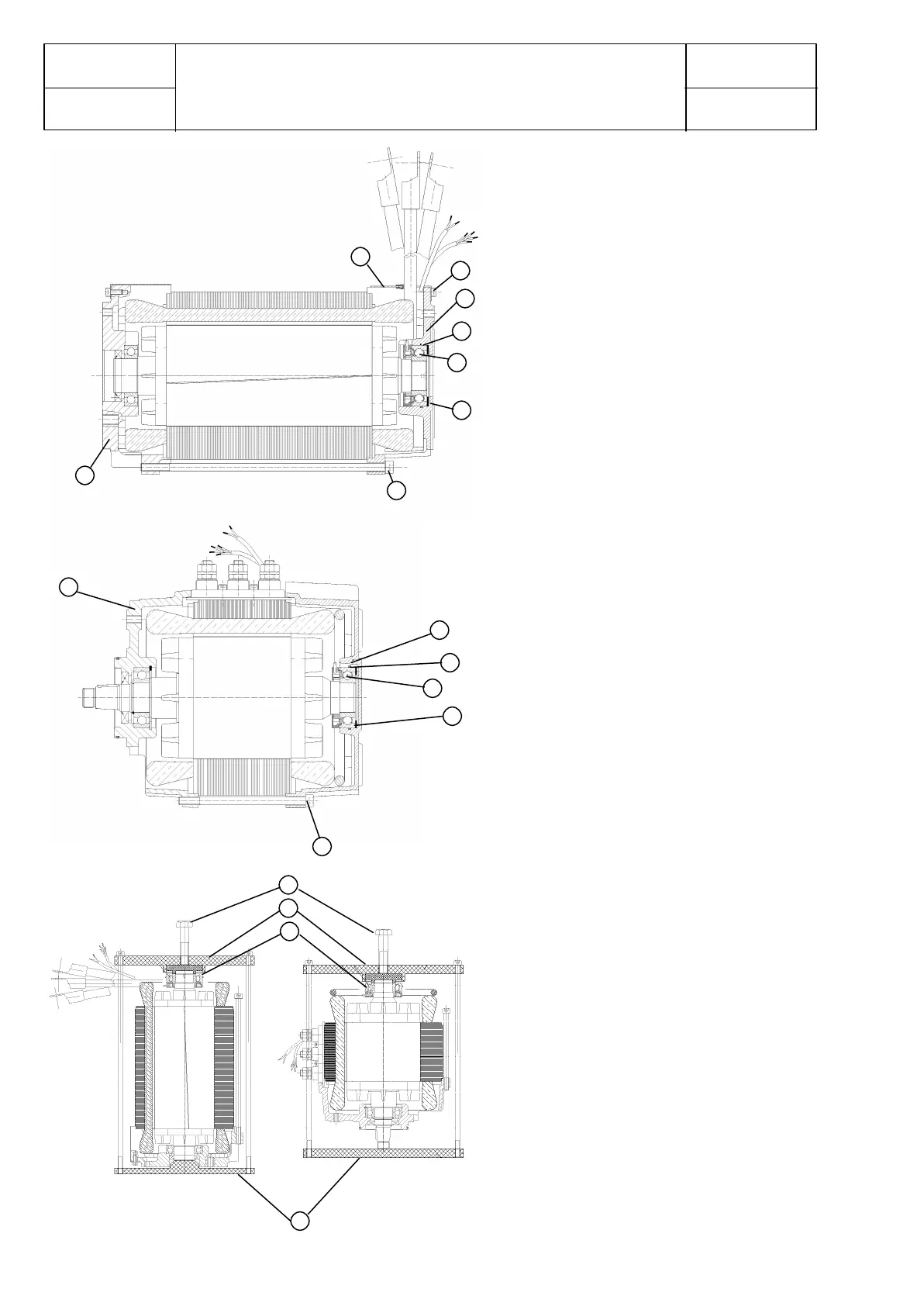

2

3

1

7

3

5

4

2

6

1

7

8

Disassembly

Disconnect the motor electrically and remove it.

Open and remove the 4 cylinder head screws

(M8x250 for the lifting motor, M8x130 for the

traction motor) Pos. 1 between non drive end

plate Pos. 2 and drive end plate Pos. 3. For the

lifting motor: take off the metal cover Pos. 4

after loosening the cylinder head screws Pos. 5

of the aluminium non drive end plate Pos. 2.

Take off the aluminium non drive end plate Pos.

2 with slight punches by means of a rubber

mallet. Remove the cable strap (which fastens

the sensor bearing cable).

Carefully remove the 2 clamping pins of the

temperature sensor from the 9-pin plug (pin

5+6). Remove the sensor bearing Pos. 6 by

means of an extractor (caution! do not damage

the centering of the shaft).

Assembly

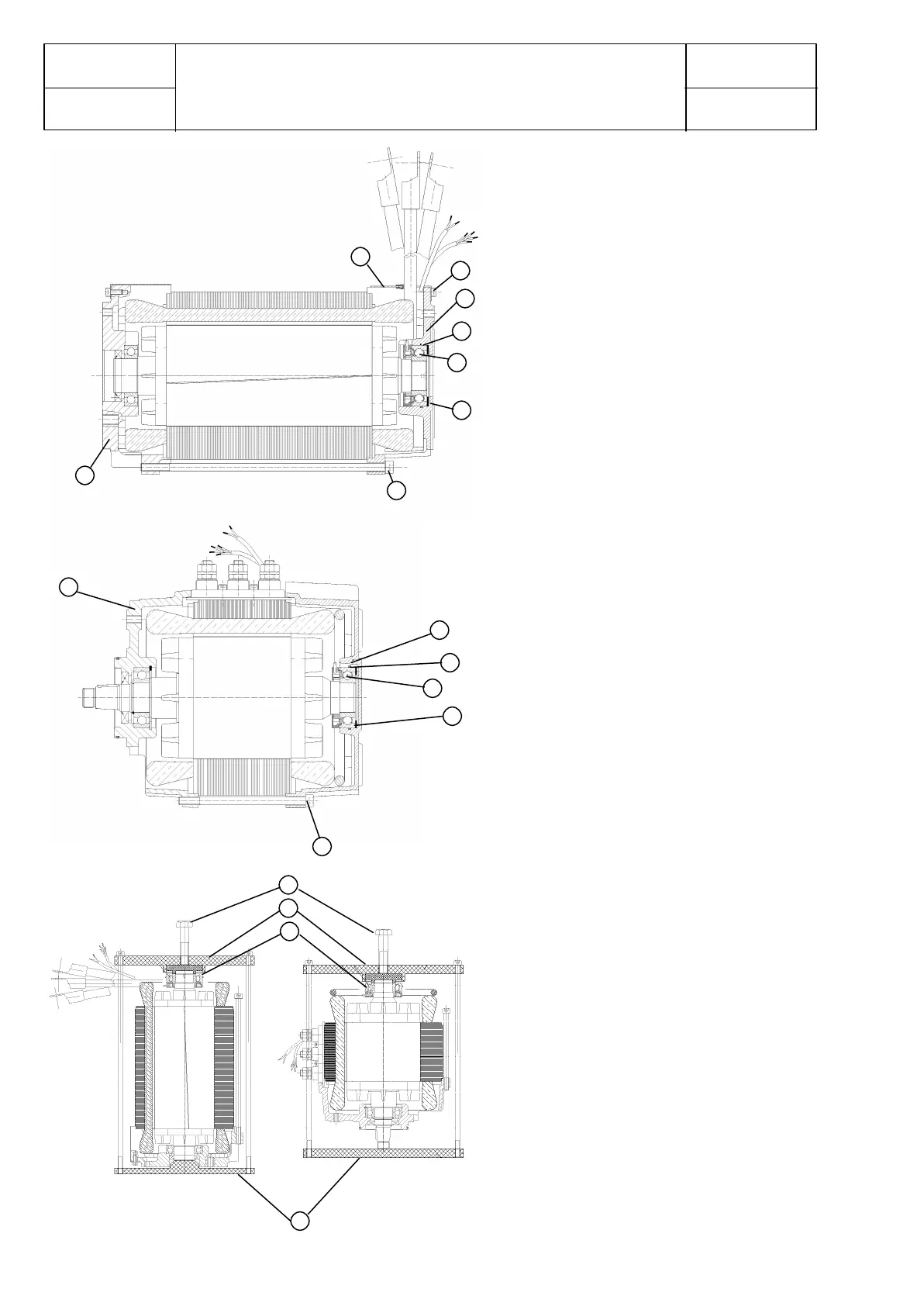

Put the motor shaft with drive end side against

the plate (Pos 9); there should be no pressure

to the drive end bearing ! Put the sensor

bearing on the shaft (Pos 6). Put the press on

device (Pos 10) on the inner ring of the sensor

bearing as shown in the drawing and fix the

device with the two longer screws. Press on the

sensor bearing with the screw (Pos 11):

Be shure to press only the inner (!) ring of

the sensor bearing.

Put the connection of the temperature sensor in

the 9-pin plug (pin 5+6) again. Secure the cable

of the temperature sensor and the sensor cable

by means of a cable strap at the motor

connecting cables. Examine the o-ring (62x2,0)

Pos. 7 inside the non drive end plate Pos. 2

regarding damages, if necessary exchange it.

Put in the wavy washer Pos. 8 inside the

aluminium non drive end plate Pos. 2 again. Put

the aluminium non drive end plate Pos..2 on the

motor again, pay attention to the position of the

cable of the sensor bearing. (Attention! Risk of

damaging the cable insulation). For the lifting

motor: put the metal cover on the aluminium

non drive end plate Pos. 2 again and fix it by

means of the cylinder head screws Pos. 5 with

a torque of 7 Nm. For the traction and lifting

motors: clamp the complete terminal between

the drive end plate Pos. 3 and the aluminium

non drive end plate Pos. 2 again. Put in the 4

cylinder head screws (M8x250 for the lifting

motor, M8x130 for the traction motor) Pos. 1

and tighten them with 11 Nm. torque for the

lifting motor or with 20 Nm. torque for the

traction motor

8

9

6

6

10

11

LIFTING MOTOR

TRACTION MOTOR

LIFTING MOTOR

TRACTION MOTOR

Loading...

Loading...