General Trouble Shooting

Below are a few general trouble shooting guidelines. If after reading this section, the condition does not

change or the condition is not covered in this section, please contact Chart’s service team at +1

408.371.4932.

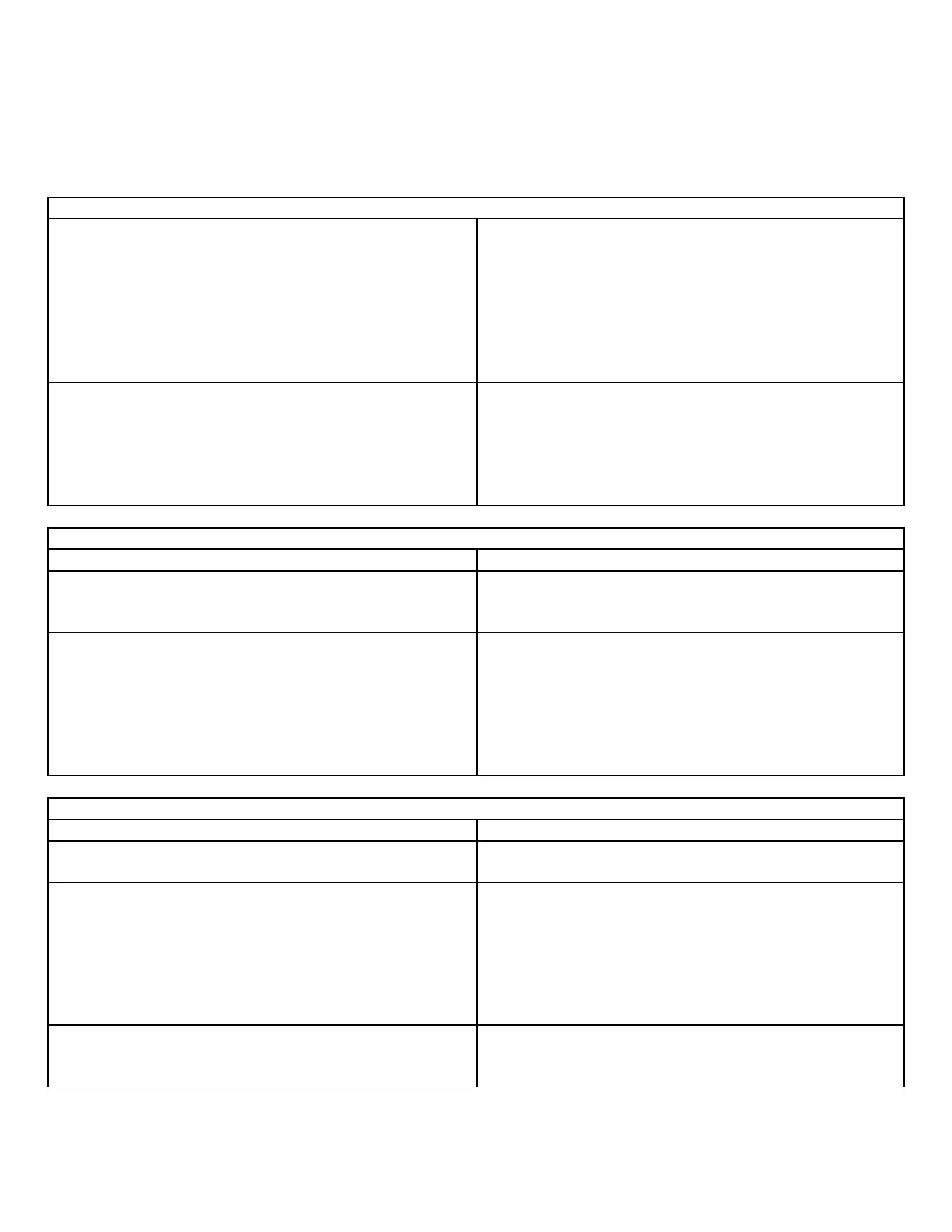

Condition: The safety relief valve is venting.

The pressure of the LN

2

supply is greater than 50

psi (3.44 bar).

Check the pressure of the LN

2

supply. If the

supply pressure is greater than 50 psi (3.44 bar),

reduce the supply pressure.

**Note: A dewar can be vented to reduce the

pressure.

The vent is obstructed.

Check the UltraDoser unit vent. If the vent is

obstructed, clear the obstruction.

If the vent is obstructed with ice, contact Chart’s

service team at +1 408.371.4932.

Condition: Liquid is coming out of the vent.

The LN

2

supply pressure is too high.

Lower LN

2

supply pressure to 22 psi (1.5 bar) or

lower.

Ice has developed inside the unit, causing the

internal float valve to malfunction.

The UltraDoser unit must be drained of liquid,

allowed to warm up over a minimum of 24 hours

with a continuous purge of warm nitrogen gas.

Contact Chart’s service team at +1 408.371.4932

for a detailed procedure.

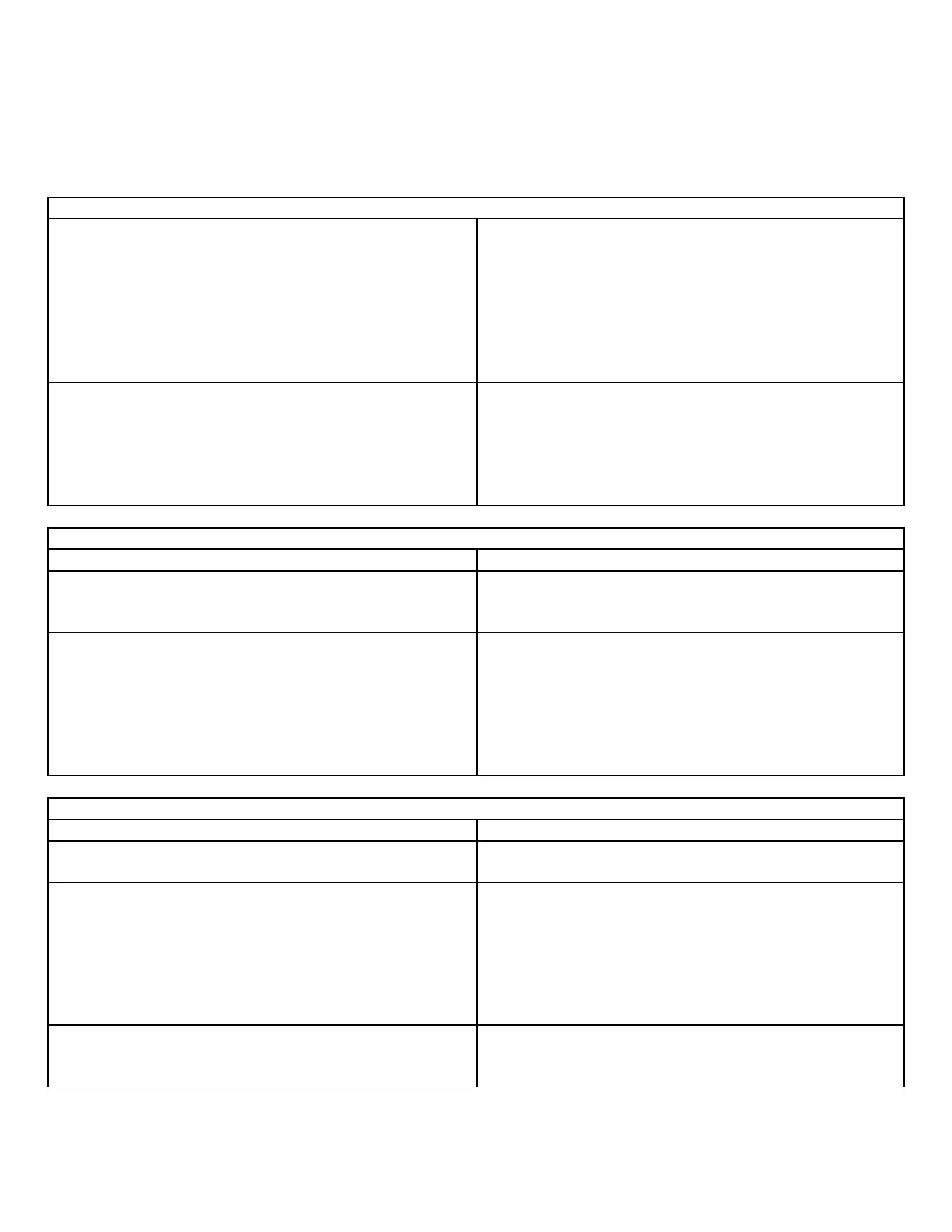

Condition: Liquid is coming out of the dosing head even though the valve is shut close.

The LN

2

supply pressure is too high.

Reduce the LN

2

supply pressure.

The valve seat is contaminated (ice or particles).

The UltraDoser unit must be drained of LN

2,

The

dosing valve assembly must be removed and

cleaned.

Contact Chart’s service team at +1 408.371.4932

for a detailed procedure.

Air supplied to the solenoid is reversed.

Reverse the LN

2

lines that supply and vent to the

solenoid.

Loading...

Loading...