FAULT #33 - Internal PLC error. PWM Pulses not seen on input

#6. – [Check the wiring to input #6 or 24VDC power.]

FAULT #34 - Internal PLC error. PWM Pulses not seen on input

#8. – [Check the wiring to input #8 or 24VDC power.]

FAULT #35 - Internal PLC error. PWM Pulses not seen on input

#10. – [Check the wiring to input #10 or 24VDC power.]

Level 5 Alarms – These alarms disable dosing. These alarms trigger a solid red light.

FAULT #50 - Estop PB not seen on input #14. – [The red

mushroom pushbutton on the front of the Doser control panel is

pushed.]

FAULT #51 - Remote Disable on. – [The remote Doser disable is

active.]

FAULT #53 - Bottle Sensor Pulses seen too fast. – [Check the

encoder. Too many pulses were detected than are allocated

between timing sensor signals.]

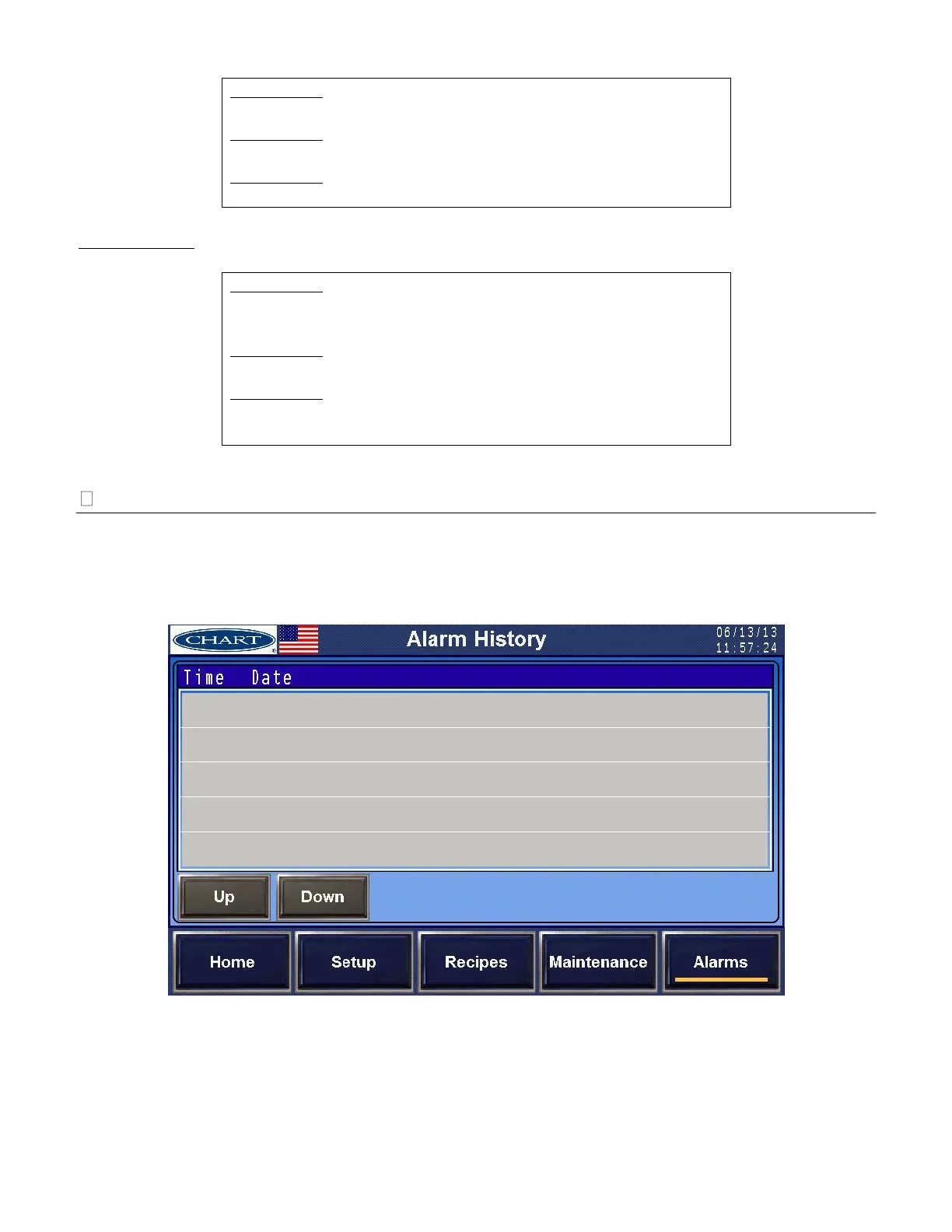

Alarm History

The alarm screen automatically clears itself of fault conditions once the fault itself has been cleared. The

Alarm History screen is similar to the Alarm screen but keeps a total history of all fault conditions. The

alarm log does not automatically clear the faults so these conditions are kept until manually cleared by the

administrator.

Loading...

Loading...