HEAT PUMPS - AIR CONDITIONING - REFRIGERATION - AIR HANDLING - HEAT EXCHANGE - NA 12.122 H

Water chillers and

air-water heat pumps

37

CIATCooler LP

Protective grille

Coil protection grille

The CIATCooler units can

include a protection grille for

the coil. This grille is fi xed by

modules in the holes made

for this purpose in the unit

supports.

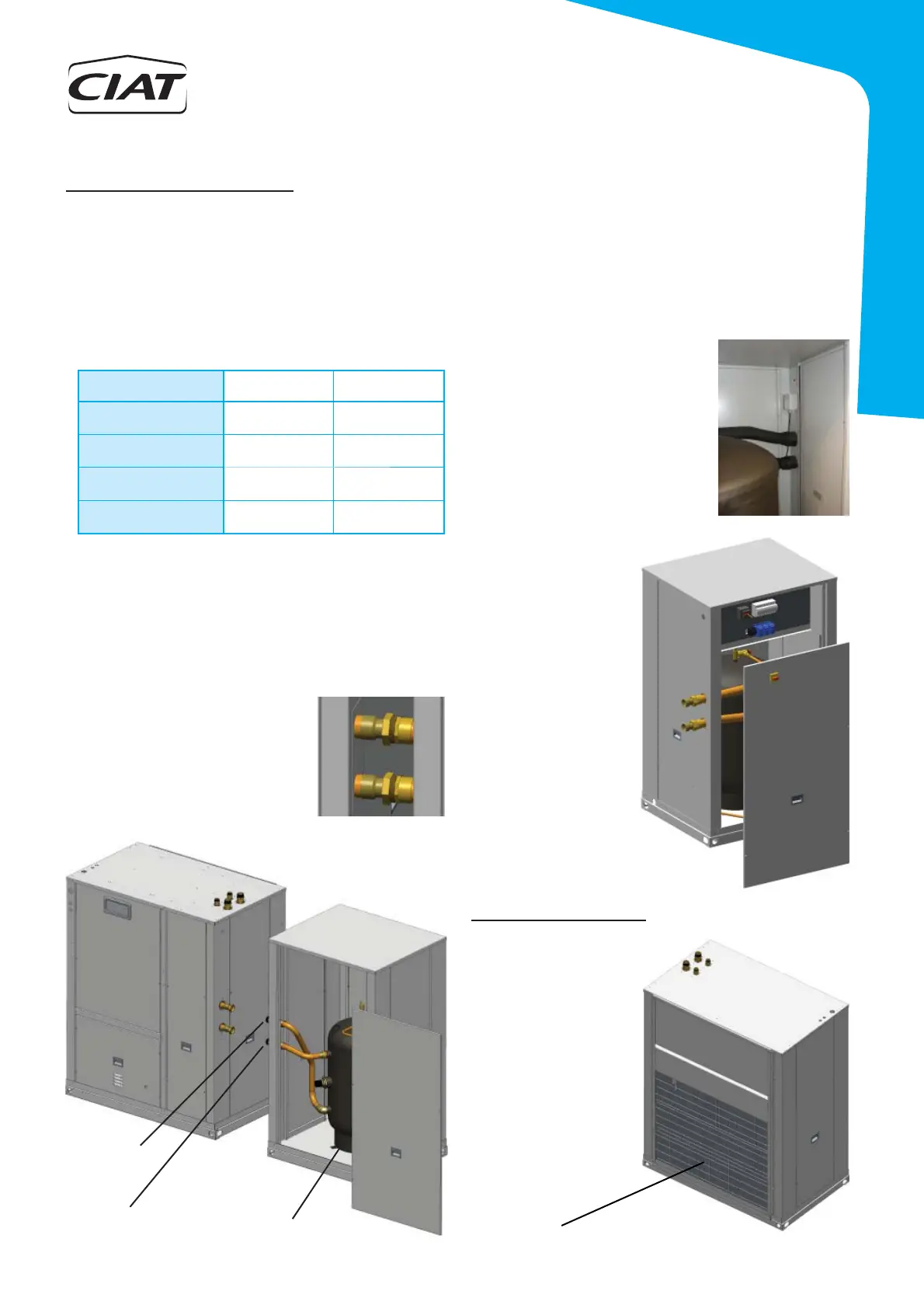

Separate

module

Ø connections

on module side

Ø connections

on unit side

90V-STD to 100V-STD

90V-HEE to 100V-HEE

1 1/4” M 1 1/4” H

120V-STD to 180V-STD

120V-HEE to 180V-HEE

1 1/2” M 1 1/2” H

200V-STD to 600V-STD

200V-HEE to 360V-HEE

2” M 2” H

640V-STD to 960V-STD

420V-HEE to 720V-HEE

2 1/2” M 2 1/2” H

Minimum distance between the unit and the separate module:

167mm. In models 640V-720V-HEE: 187mm.

Separate hydraulic module

A hydraulic module can be coupled to units with LPC / ILPC version.

This one includes a thermal buffer tank made of black stainless steel,

painted, and thermally insulated.

The module can be supplied:

- Coupled to the LPC / ILPC unit, models 90 to 360 (STD version) and

90 to 280 (HEE version).

- Separate for connection on site by the installer. The diameters of the

hydraulic connections between the unit and the module are:

In this case, the fl exible connections of 500 mm are recommended

(option).

Note: In order that the unit with hydraulic module could incorporate

the option of antifreeze protection with fl exible electric heaters on the

hydraulic circuit piping, the module must be coupled to the unit, or in

the case of separate, do not add additional

elements in the threaded connections

between module and unit, and isolate

these connections.

Therefore, antifreeze protection on piping

is not compatible with fl exible hydraulic

connections.

LPC / ILPC

Hydraulic module

Buffer tank

Water inlet

to the tank

Water outlet

from the tank

The buffer tank includes an anti-freeze electrical heater (1kW).

Optionally, in heat pump units, this heater can be replaced by a support

heater in 1 to 4 stages.

With separate hydraulic module, the installer must perform the wiring

from this module to the electric panel of the machine.

* 1 power stage: the terminal block for

connecting the electrical heater to the unit

are located in a box inside the module,

on the same pillar that the hydraulic

connections.

- Anti-freeze electrical heater (1 kW):

230V / I ph 2-wire + ground

- Support electrical heater (3 to 12 kW):

400 V / III ph 3-wire + ground

Wiring of the buffer electric support

* 2 to 4 power stage (24

to 48 kW): the module

incorporates an auxiliary

electric panel, 3-wire

power supply (door switch)

+ ground + 6 to 8-wire (2

to 4 stages) in a terminal

block for connection of

electrical heaters (see

wiring diagram).

Loading...

Loading...