Water chillers and

air-water heat pumps

HEAT PUMPS - AIR CONDITIONING - REFRIGERATION - AIR HANDLING - HEAT EXCHANGE - NA 12.122 H

44

CIATCooler LP

Recommendations

- Do not lean on the unit. A platform must be used to work on a level.

- Do not lean on the copper refrigerant tubes.

- Keep the unit clean.

- Keep the space surrounding the unit clean and cleared in order to

avoid accidents and ensure the proper ventilation of the coil.

- Perform a visual (remains of water or oil below or around the unit)

and auditory inspection of the entire installation.

- In general, a corrosion control must be performed on the metallic

parts of the unit (frame, bodywork, exchangers, electric panel, etc.).

- Check that the insulation foam is not unstuck or torn.

- All the electric connection states must be checked as well, as well

as the air tightness of the different circuits.

Next, some recommendations are stated for performing the

maintenance and cleaning of the unit's components:

13. MAINTENANCE

The minimal maintenance operations and their periodicity will be made

according to the national regulations.

Any intervention on the electric cooling components must be made by

a qualifi ed and authorized technician.

Technicians who intervene with the unit must use the necessary

safety equipment (gloves, goggles, insulating clothing, safety shoes,

etc.). Furthermore, if working around sources of signifi cant noise, we

recommend the use of noise-dampening headgear.

V-220004

Caution: Before intervening in the unit, cut off main

power.

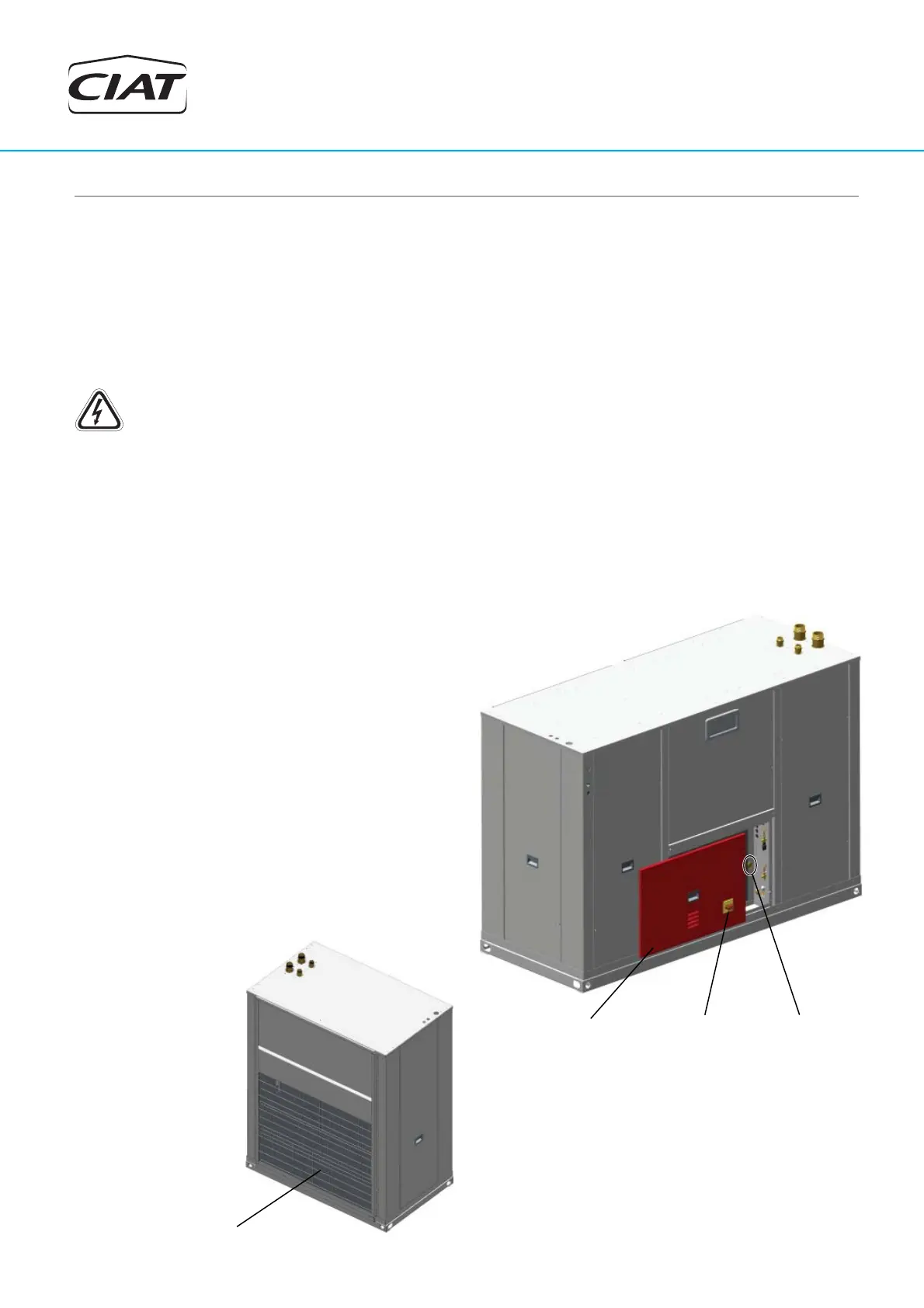

Liquid sight glass (available from the model 200)

This sight glass, located on the liquid line, after the dehydrating fi lter,

enables controlling the refrigerant load and the presence of moisture

in the circuit. The presence of bubbles in the indicator means that

the refrigerant fl uid load is insuffi cient (see chapter 4 "Technical

characteristics") or that there are non-condensable products in the

cooling circuit. The presence of moisture is characterised by the change

in colour of the control paper located on the sight glass.

On CIATCooler units, the liquid sight glass is accessed via the electric

panel access panel (please, consult the section “refrigerant charge

load”).

Warning:

If the unit stops, certain indicators may appear in yellow; the change

in colour is due to the sensitivity, which depends on the temperature

of the fl uid.

These will change to green after a few hours of the unit operating.

If the indicators remain yellow, that will indicate the presence of

excessive humidity in the circuit. This will require the presence of a

specialist.

Air coil

- Check that the coil is free from dust and grease.

- Cleaning the accumulated dust on the coil can be performed with

a vacuum cleaner perpendicular to the fi ns or with a low-pressure

water cleaner. Grease can

be removed with water

with degreaser. Do not put

stress on the fi ns as they

could deform.

- If the unit includes a

protective grille for the

coil (optional), it will be

necessary to remove this

one. The grille is fi xed by

modules in the holes made

for this purpose in the unit

supports.

Protective grille

Access to the

electric panel

Door

switch

Liquid sight

glass

Dehydrating fi lter

- The fi lter function is to keep the cooling circuit clean and without

humidity, neutralising the acids that can be found in the cooling circuit.

- Verify dirt measuring the difference in temperature at the piping level,

at the inlet and at the outlet of the dehydrant.

- If necessary, replace.

Loading...

Loading...