HEAT PUMPS - AIR CONDITIONING - REFRIGERATION - AIR HANDLING - HEAT EXCHANGE - NA 12.122 H

Water chillers and

air-water heat pumps

45

CIATCooler LP

Plate exchanger

- The exchangers are fi tted with thermal insulation. Check that the

foam is not unstuck or broken.

- The water quality and the pressure drop must be verifi ed at the ex-

changer level. After verifying the mesh fi lter condition, if necessary, the

exchanger must be cleaned. To this end, a weak solution of phosphoric

acid 5% must be circulated using the high pressure pump. During

optimum cleaning, the cleaning solution fl ow must, as a minimum,

be 1,5 times the working fl ow, preferably in the inverse circulation

mode. This must be followed by thorough rinsing with water to remove

any acidic residues. It is advisable to circulate a solution 1%-2% of

sodium hydroxide prior to the last rinsing in order to ensure that the

acid has been neutralised.

- Any repair or modifi cation to the plate exchanger is prohibited. It can

only be replaced by an original part.

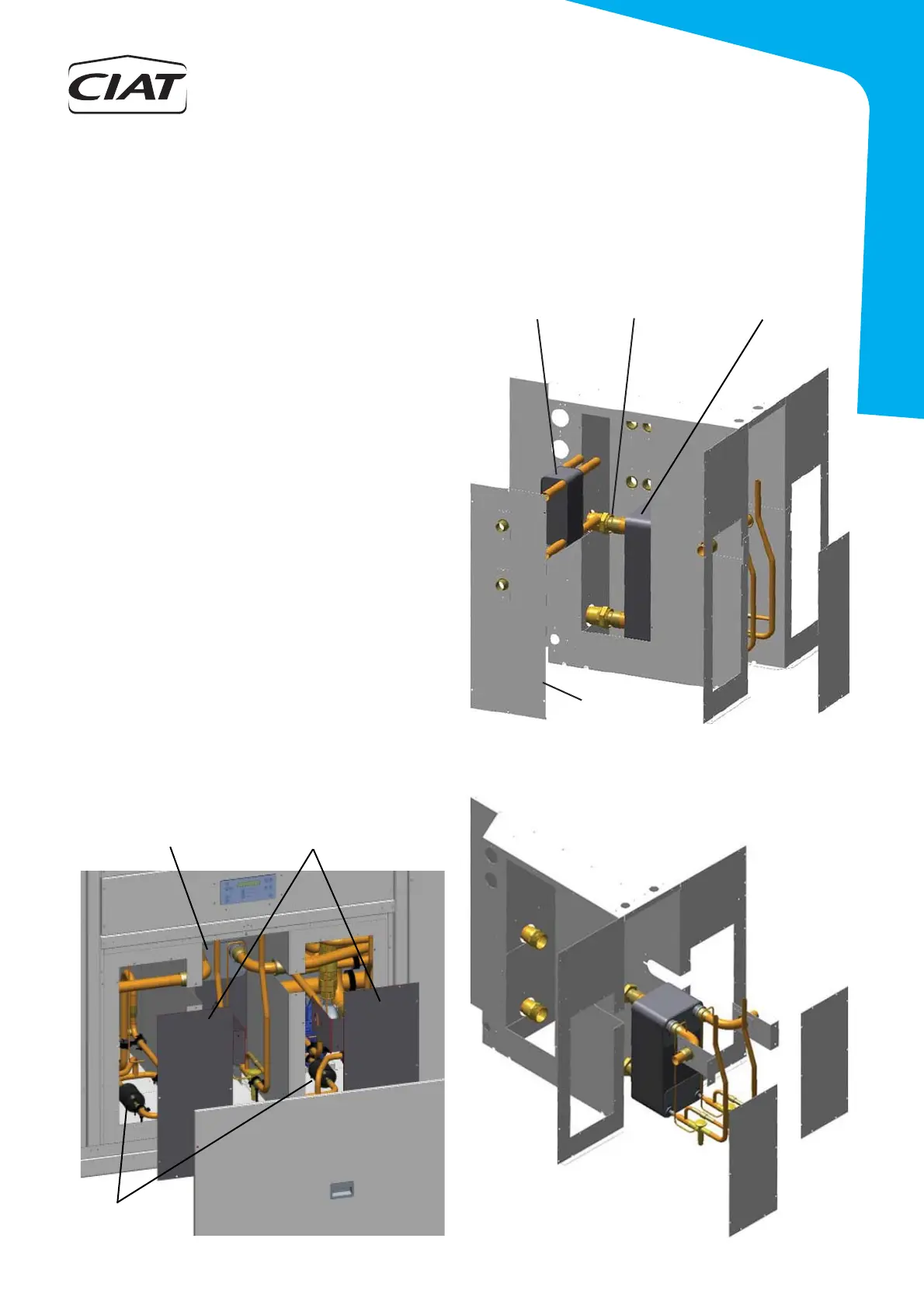

• Access to the plates exchangers both the main circuit and the

recovery circuit in models 640 to 960 STD and 420 to 720 HEE:

Because it is a dual plates exchanger, is it located in the central

area of the unit, on the axis of symmetry of the two circuits. If the

exchanger have to be replaced, the two panels indicated in this

image must be removed.

Dehydrating

fi lters

Plates exchager

Panels

- To be able to unscrew the water connections of the exchanger, the

unit incorporates another movable panel which is accessed by the

door on the left side of the above door. By registering also accessed

the recovery exchanger.

Plate exchanger

of the main

circuit

Plate exchanger

of the recovery

circuit

Water

threaded

conections

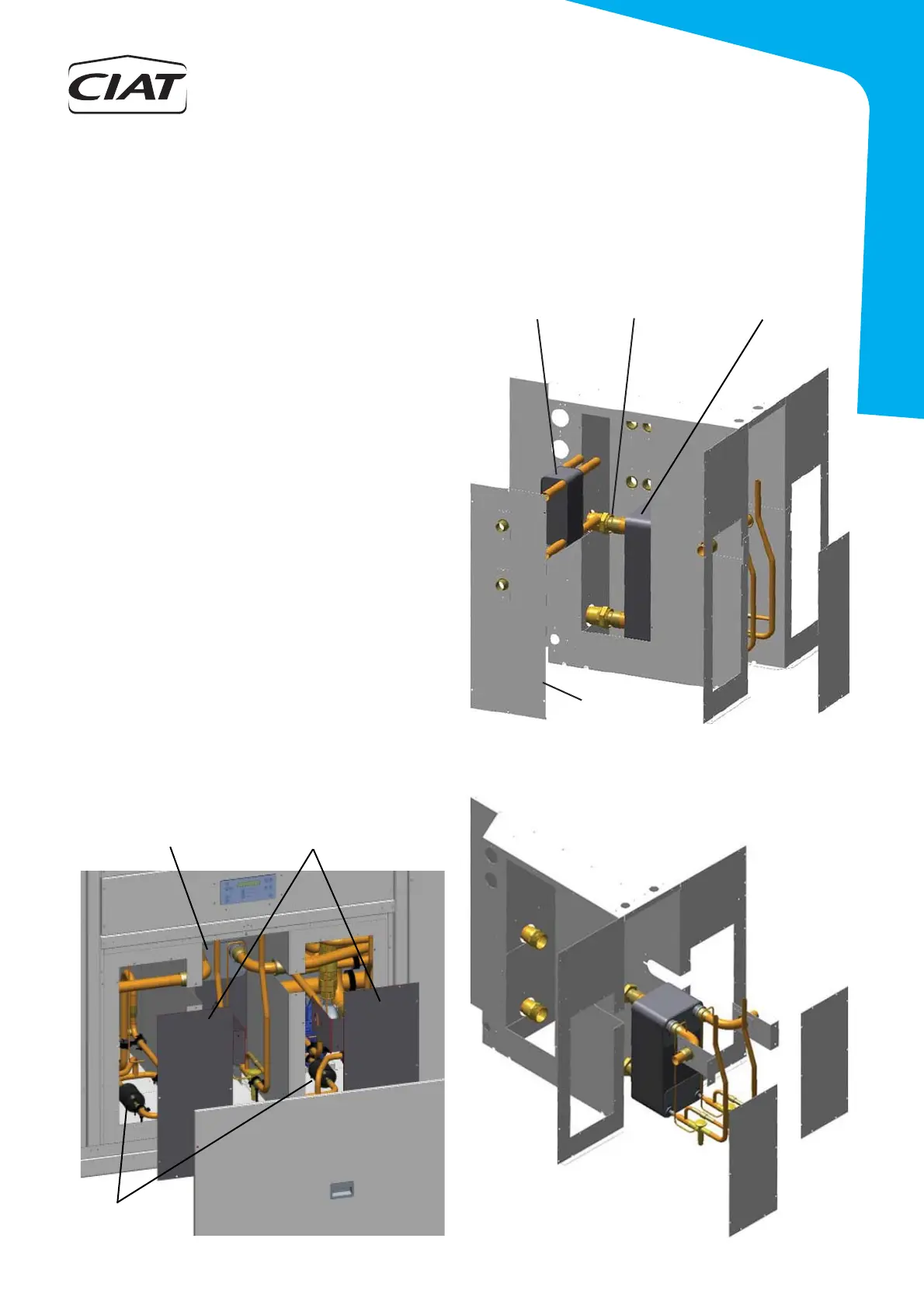

In the following image it is possible to observe the plate exchanger of

the main circuit extracted .

Access

panel

Mesh fi lter

- It is also necessary to install a fi lter in the hydraulic power

supply to the unit in order to prevent clogging of the plate

exchanger.

- For LPC/ILPC units, a kit with a stainless steel mesh fi lter (500

microns) is also supplied for installation by the installer. Optionally,

this fi lter can be supplied for LP/ILP units.

- The fi ltering mesh must be removed and cleaned in order to clean

the fi lter.

Loading...

Loading...