Water chillers and

air-water heat pumps

HEAT PUMPS - AIR CONDITIONING - REFRIGERATION - AIR HANDLING - HEAT EXCHANGE - NA 12.122 H

46

CIATCooler LP

Centrifugal fan (STD version)

- Verify that the turbine and the motor remain clean.

- Foresee having a spare belt set for the fans.

- The motors and the fans have bearings that have been lubricated and

sealed and, thus, do not need further lubrication (except in the case

of fans with a reinforced shaft).

Servomotor (optional)

In CIATCooler units with a condensation pressure regulation

damper (in the STD version), it is advisable to check the state of the

servomotor.

Note: The damper in models 420V-STD to 600V-STD incorporates 2

sevomotors (one on each side).

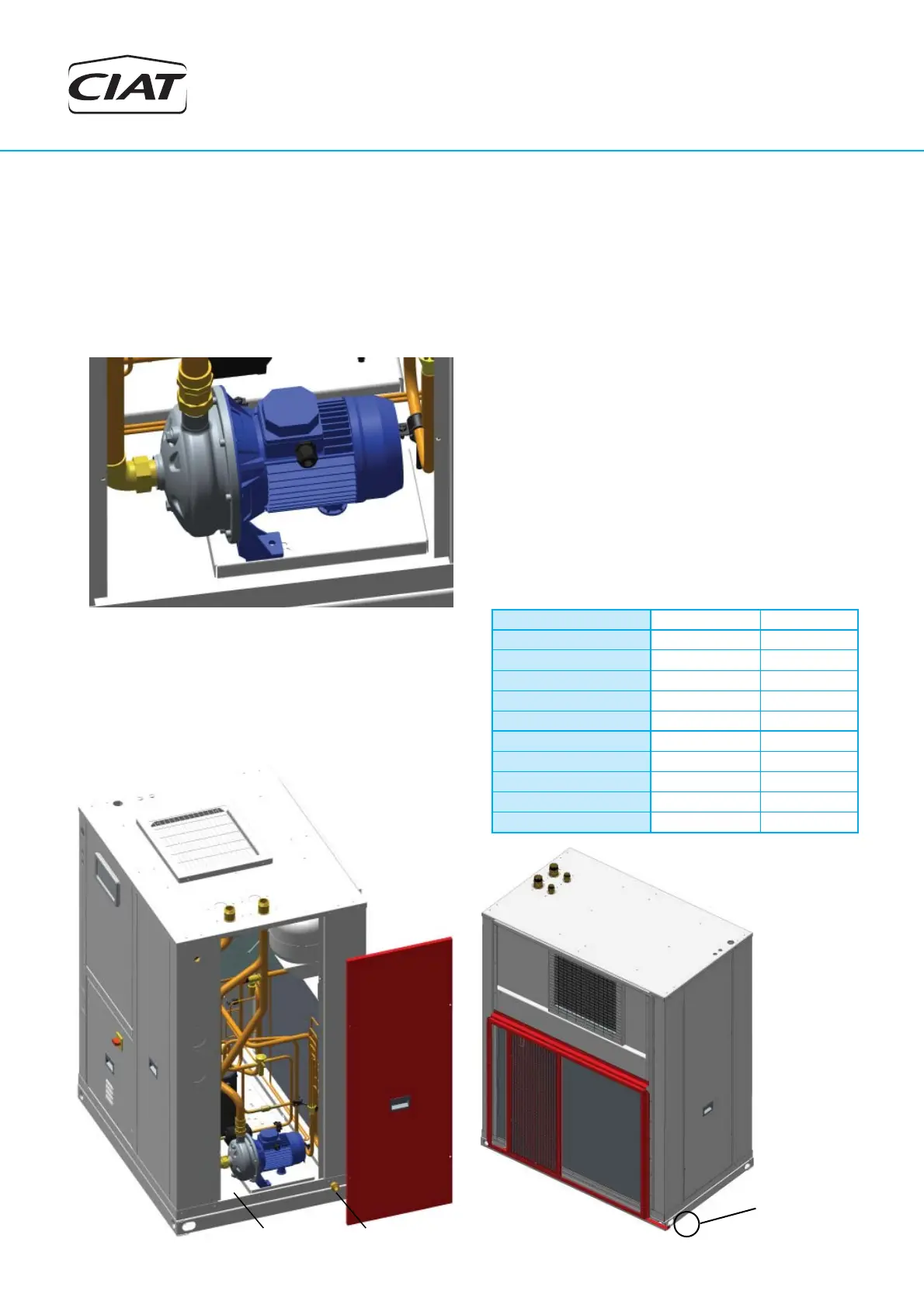

Pump

In the case of pump replacement:

- Disconnect the unit from power supply.

- Disconnect electrically the pump.

- Empty completely of water from the hydraulic circuit.

- Loosen the fi ttings of the 2 pipes.

- Remove the two screws fi xing the pump and replace it.

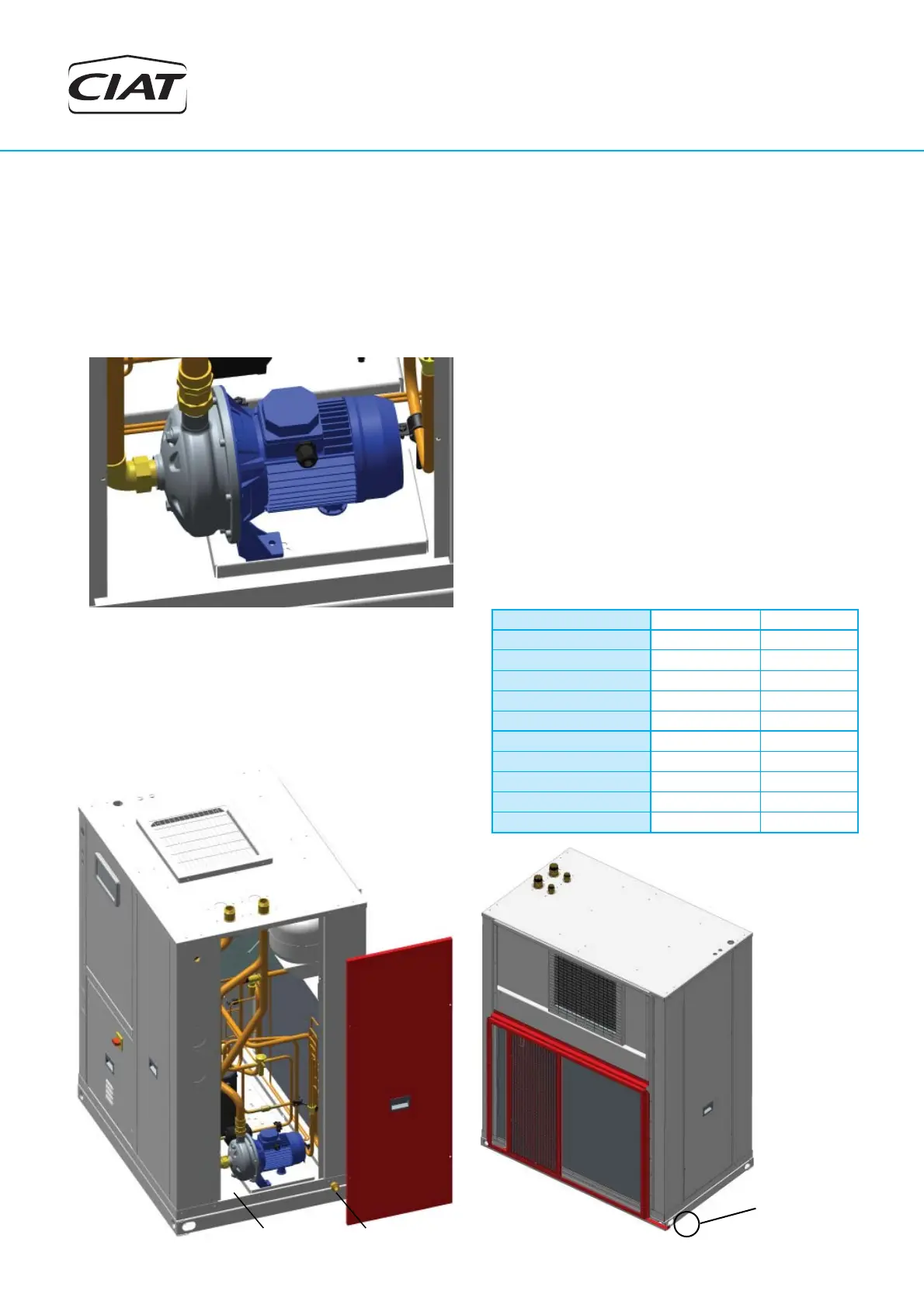

Condensate pan Drain

Filter in the return air (optional)

- Clean usually. Depending on the installation conditions, the fi lter

aspect must be examined to defi ne the cleaning periodicity.

- Gravimetric fi lters: Cleaning the fi ltering mesh can be done with a

household vacuum cleaner, or by submerging it in water.

Filters are moved

by lifting the tab

and dragging

CIATCooler Number of frames Number of cell

90V-STD to 100V-STD

12

120V-STD to 180V-STD

13

200V-STD

24

240V-STD to 600V-STD

26

640V-STD to 960V-STD

2 16

90V-HEE

12

100V-HEE to 120V-HEE

13

160V-HEE to 180V-HEE

24

200V-HEE to 360V-HEE

26

420V-HEE to 720V-HEE

2 16

Condensate drain pan

- Check that the condensate pan is clean.

- Check that the drain is not clogged.

- Cleaning of the pan can be done with water and non-abrasive

detergent.

Loading...

Loading...