Water chillers and

air-water heat pumps

HEAT PUMPS - AIR CONDITIONING - REFRIGERATION - AIR HANDLING - HEAT EXCHANGE - NA 12.122 H

38

CIATCooler LP

Cooling recovery circuit

The system consists in a hot water supplying by an heat recovery

system on the compressor(s) discharge gas, on an auxiliary

desuperheater exchanger.

On an heat pump model, the optional desuperheater can be used

whatever the running mode, COOLING or HEATING.

This optional equipment is only available on request, and factory

mounted.

Operating mode

The heat recovery is possible only if the unit is running, on COOLING

mode or on HEAT PUMP mode.

For the same cooling or heating capacity, the desuperheater system

allows a free heating of hot water with a reduction of the total input

power of the unit.

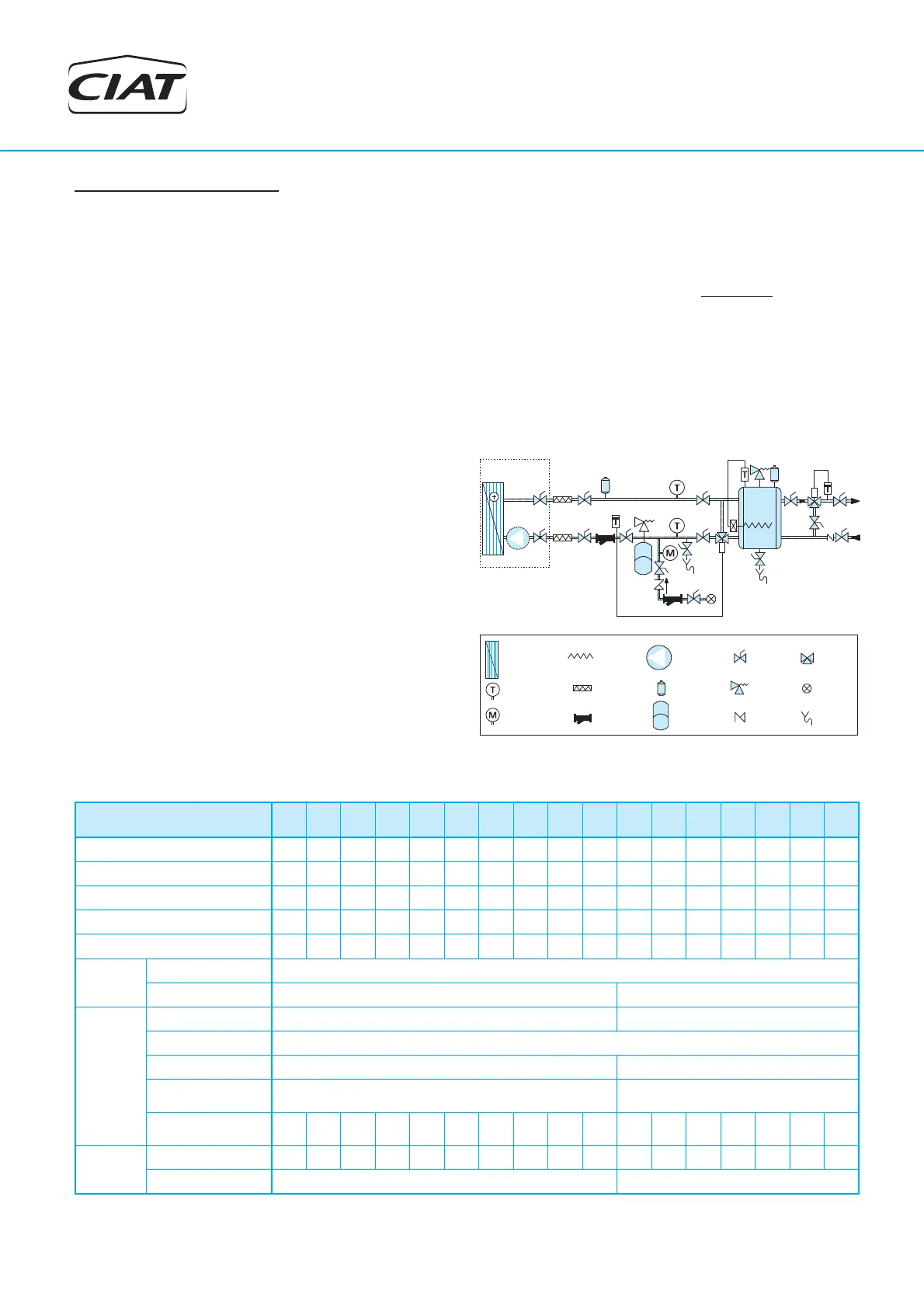

Principle and precaution of hydraulic connection

In order to allow the unit to start up and to run under good conditions,

the circuit must be as short as possible, and the water fl ow of the

desuperheater must start slowly to normal operating condition, with a

water fl ow equal to 10% of its standard value, and must be calculated

for a hot water inlet temperature of +50°C.

Thus, it is recommended to have a hydraulic diagram making it possible

to obtain very quickly a hot water at the inlet of the desuperheater (3 ways

valve + controller + temperature sensor on the exchanger water inlet).

The controller set point must be adjusted to +50°C minimum.

The recovery circuit must be done in accordance with the standards

in force and plan all of the necessary elements in a closed circuit:

circulation pump (optionally supplied), expansion vessel, safety valve,

mesh fi lter, fi ller, drainer, bleeders, thermometers, pressure gauges and

cut-off and insulation valves.

The circulation pump can only work in a closed circuit. The command

is performed from a thermostat located on the unit.

Attention: a detailed attention must carried with the selection of the

expansion tank, because the recovery water circuit can reach the

temperature of 120°C in the event of stopping of the circulator or non

hot water consumption.

- Install heating elements on all pipes that could be exposed to freezing

temperatures.

PLATES

EXCHARGER

EXPANSION

VESSEL

ELECTRICAL

HEATER

MESH

FILTER

VA

SHUT-OFF

LVE

DRAINAGE

CIRCUIT

SAFETY

VALVE

NO RETURN-

VALVE

VA

AIR BLEEDER

LVE

THERMOMETER

MANOMETER

CIRCULATOR

PUMP

FILLED

CIRCUIT

3-WAY

VALVE

FLEXIBLE

CONNECTION

Agua de red

A consumo

Opcional

CIATCooler

Min. 50ºC

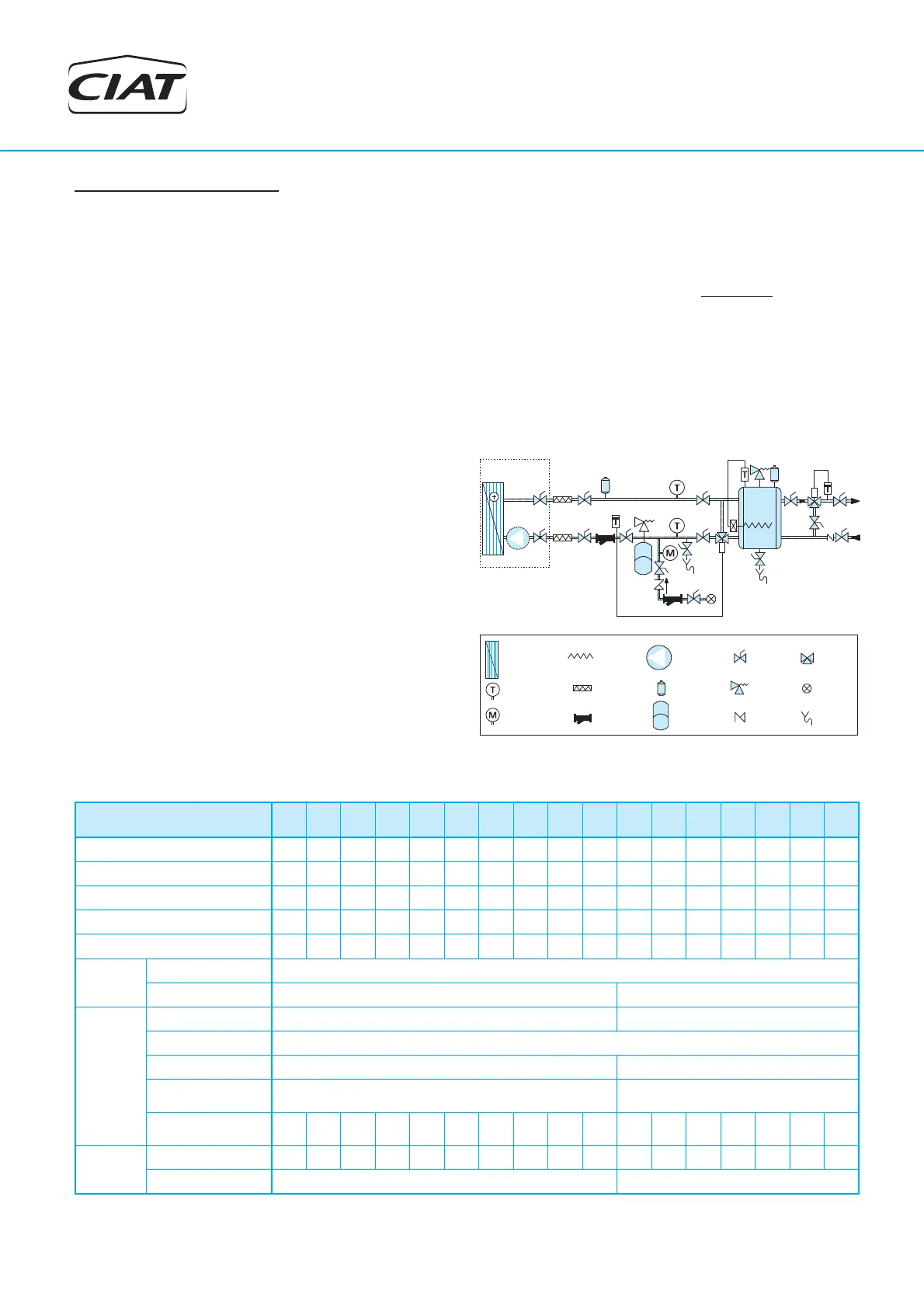

Technical characteristics of the recovery circuit with the STD version

Capacity recovered by the desuperheater circuit for nominal conditions and recovery water at 50/60ºC.

Models 90 to 360, the change of speed of the pump is made by a button that changes color according to the selected speed (blue: low; green: medium; yellow: high).

CIATCooler

90V-

STD

100V-

STD

120V-

STD

160V-

STD

180V-

STD

200V-

STD

240V-

STD

280V-

STD

320V-

STD

360V-

STD

420V-

STD

480V-

STD

600V-

STD

640V-

STD

720V-

STD

840V-

STD

960V-

STD

Recovery capacity (kW)

4,4 5,2 6,2 8,1 8,9 10,8 12,2 13,8 16,8 18,3 21,9 23,9 29,4 33,2 37,7 43,9 47,5

Nominal water fl ow (m

3

/h) 0,38 0,45 0,53 0,70 0,76 0,93 1,05 1,18 1,44 1,58 1,88 2,06 2,53 2,85 3,24 3,77 4,08

Pressure drop (m.w.c.) 0,06 0,09 0,17 0,30 0,36 0,53 0,67 0,32 0,48 0,57 1,15 1,38 2,08 1,33 2,31 3,13 3,74

Cooling capacity (kW) 17,8 21,3 25,3 33,0 36,2 44,0 49,6 56,1 68,3 74,6 89,3 97,6 119,7 135,2 153,1 178,2 194,5

Power input (kW) 6,8 7,9 8,6 10,8 12,7 15,6 17,0 19,5 21,7 25,5 28,1 32,2 42,3 40,5 49,9 56,0 65,3

Hydraulic

connections

Type Threaded

Diameter 1” M 1 1/4” H

Pump

(optional)

Type Humid rotor Dry rotor

Number 1

Motor output (kW) 0,05 0,25

Maximum absorbed

current (A)

0,4 2,0

Avail. pressure (m.w.c.)

(max. pump speed)

5,54 5,45 5,35 5,15 5,07 4,85 4,69 4,49 4,11 3,90 11,18 11,03 10,61 10,32 9,47 8,88 8,47

Additional

weight

Recovery circuit (kg) 5,3 5,3 6,8 6,8 6,8 10,7 11,6 11,6 11,6 11,6 21,9 22,0 21,9 57,7 56,1 59,4 59,6

Pump (optional) (kg) 3,2 14,6

Loading...

Loading...