HEAT PUMPS - AIR CONDITIONING - REFRIGERATION - AIR HANDLING - HEAT EXCHANGE - NA 12.122 H

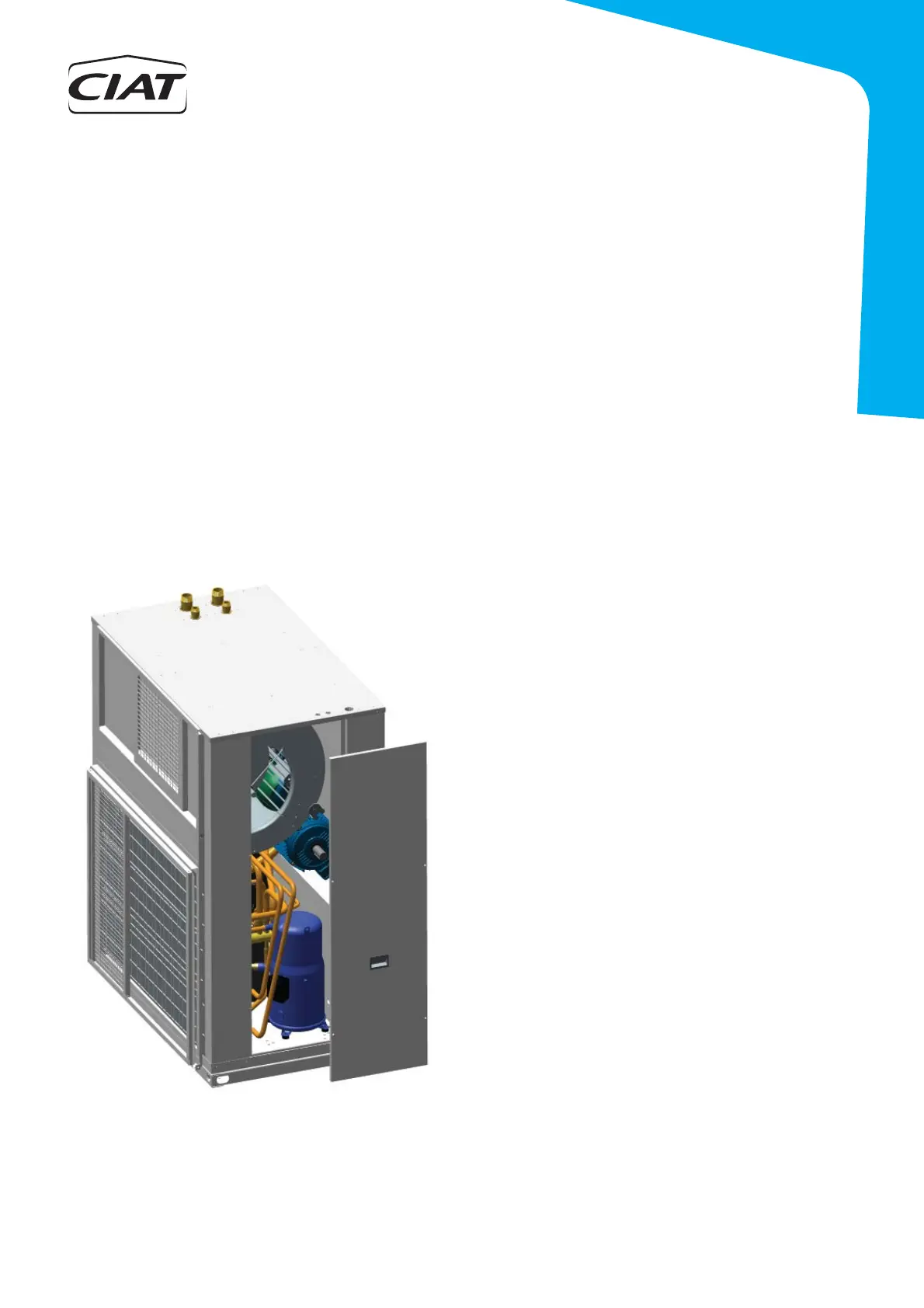

Water chillers and

air-water heat pumps

47

CIATCooler LP

Refrigerant

Only qualifi ed personnel must perform a periodic tightness control, in

accordance with the regulation (CE) Nº 517/2014.

- The frequency of checks is no longer related to the load of refrigerant

but to its global warming potential:

Load kg x GWP = t CO2e

Carbon dioxide equivalency (t CO2e ) is a quantity that describes, for

a given mixture and amount of greenhouse gas, the amount in tonnes

of CO2 that would have the same global warming potential (GWP).

Please, consult data of carbon dioxide equivalency (t CO2e) provided

in the technical characteristics table (chapter 4).

- Operators shall ensure that the unit is checked for leaks ad minima

according to the following frequency:

• t CO2e < 5 ............ not subjected

• t CO2e 5 to 50 ...... every year

• t CO2e 50 to 500 ... every 6 months

• t CO2e > 500 ......... every 3 months

- Where a leakage detection system has been installed the frequency

of checks is halved.

Note: Never forget that the cooling systems contain liquids and vapours

under pressure. The service pressure of R-410A is approximately 1.5

higher than that of R-407C.

- All necessary precautions must be taken during the partial opening

of the cooling circuit. This opening entails the discharge of a certain

amount of refrigerant to the atmosphere. It is essential to limit this

quantity of lost refrigerant to a minimum by pumping and isolating

the charge in some other part of the circuit.

- The refrigerant fl uid at low temperature can cause infl ammatory in-

juries similar to burns when contacting the skin or eyes. Always use

safety goggles, gloves, etc. when opening ducts that may contain

liquids.

- The refrigerant in excess must be stored in appropriate containers

and the amount of refrigerant stored at the technical rooms must be

limited.

- Refrigerant barrels and deposits must be handled with precaution

and visible warning signs must be placed to attract attention over

the risks of intoxication, fi re and explosion linked to the refrigerant.

- At the end of its useful life, the refrigerant must be retrieved and

recycled as per the current regulations.

Oil

Oils used for cooling machines do not post any threat to one's health

if used while following the usage guidelines:

- Avoid any unnecessary manipulation of the elements covered in oil.

Use protection creams.

- Oils are fl ammable and must be stored and handled with precaution.

"Disposable" rags or towels used for cleaning must be kept away

Compressor

In the case of compressor replacement:

- Disconnect the unit from power supply.

- Completely empty the load of refrigerant using a specifi c recovery

unit for R-410A

- Disconnect electrically the compresor.

- Carefully unscrew the suction and discharge piping.

- The compressor is fi xed onto the platform with 4 screws Ø 8 mm.

Unscrew the fi xings.

- Place the new compressor and check that it has a suffi cient oil charge.

Warning: when tightening the compressor screws, please consult

the maximum torque that can be applied.

If a torque wrench is not available, tighten them until noticing

resistance, then tighten the screws by turning them 3/4 of a revolution.

- Screw the suction and discharge piping.

- Connect the compressor in accordance with the circuit diagram.

- Make vacuum and next, reload the gas into the unit according to

load data provided in the technical characteristics table and in the

unit’s data plate.

from open fl ames and must be discarded by using the appropriate

procedure.

- Jugs must be kept closed. Avoid using oil from an already-open jug

kept in poor conditions.

Both the oil type as well as the volume needed for each model are

stated in the characteristics table in chapter 4.

- Check the oil level and aspect. In case of a colour change, check

the oil quality using a contamination test.

- In the case of the presence of acid, water or metallic particles, replace

the affected circuit oil, as well as the dehydrant fi lter.

- In the event of an oil charge change, only new oil will be used, which

will be identical to the original oil and taken from a jug tightly closed

until the moment of the charge.

Loading...

Loading...