MIG (GMAW) WELDING 5-4 Manual 0-5492

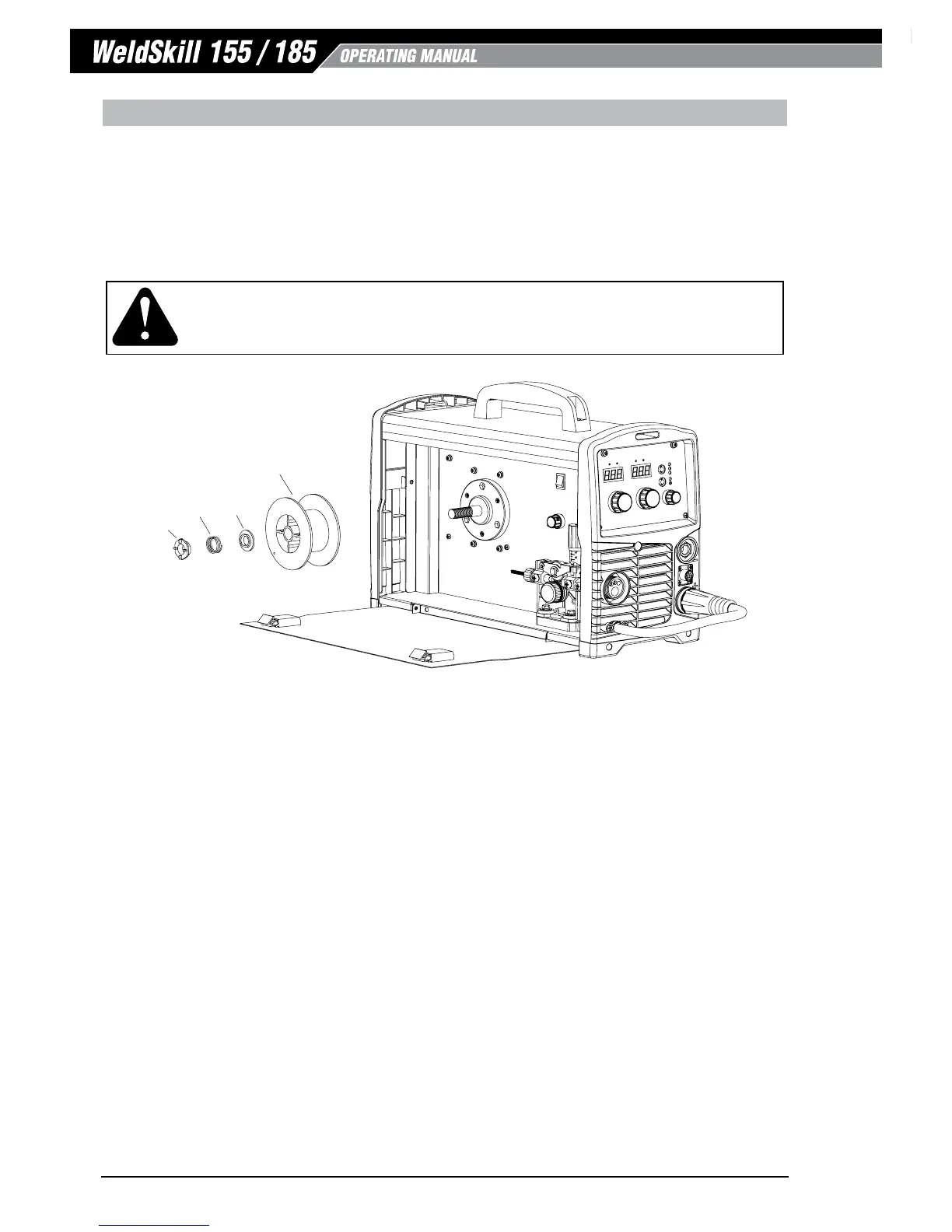

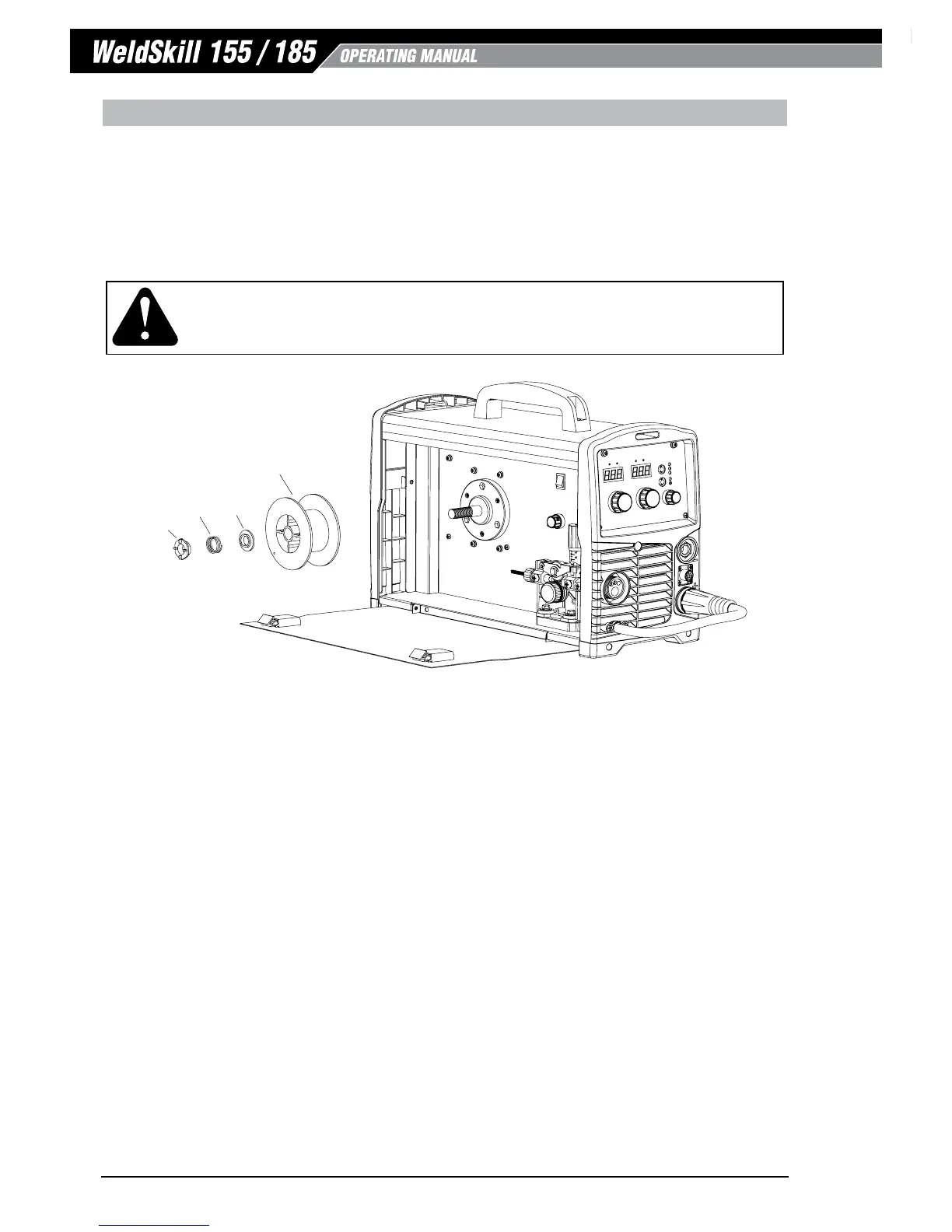

5.03 Installing Minispool (100mm diameter)

As delivered from the factory, the unit is fitted with a Wire Spool Hub which accepts a Handispools of 200mm

diameter.

In order to fit a Minispool (100mm diameter) assemble parts in the sequence shown below in Figure 5-4.

The nut and spring tighten the brake. The brake is correctly adjusted when the spool stops within 10 to 20mm

(measured at the outer edge of the spool) after Mig Torch trigger is released. Wire should be slack without

becoming dislodged from the spool.

CAUTION

Overtension of brake will cause rapid wear of mechanical WIREFEED parts, overheating of electrical componentry and

possibly an increased incidence of wire Burnback into contact tip.

Loading...

Loading...