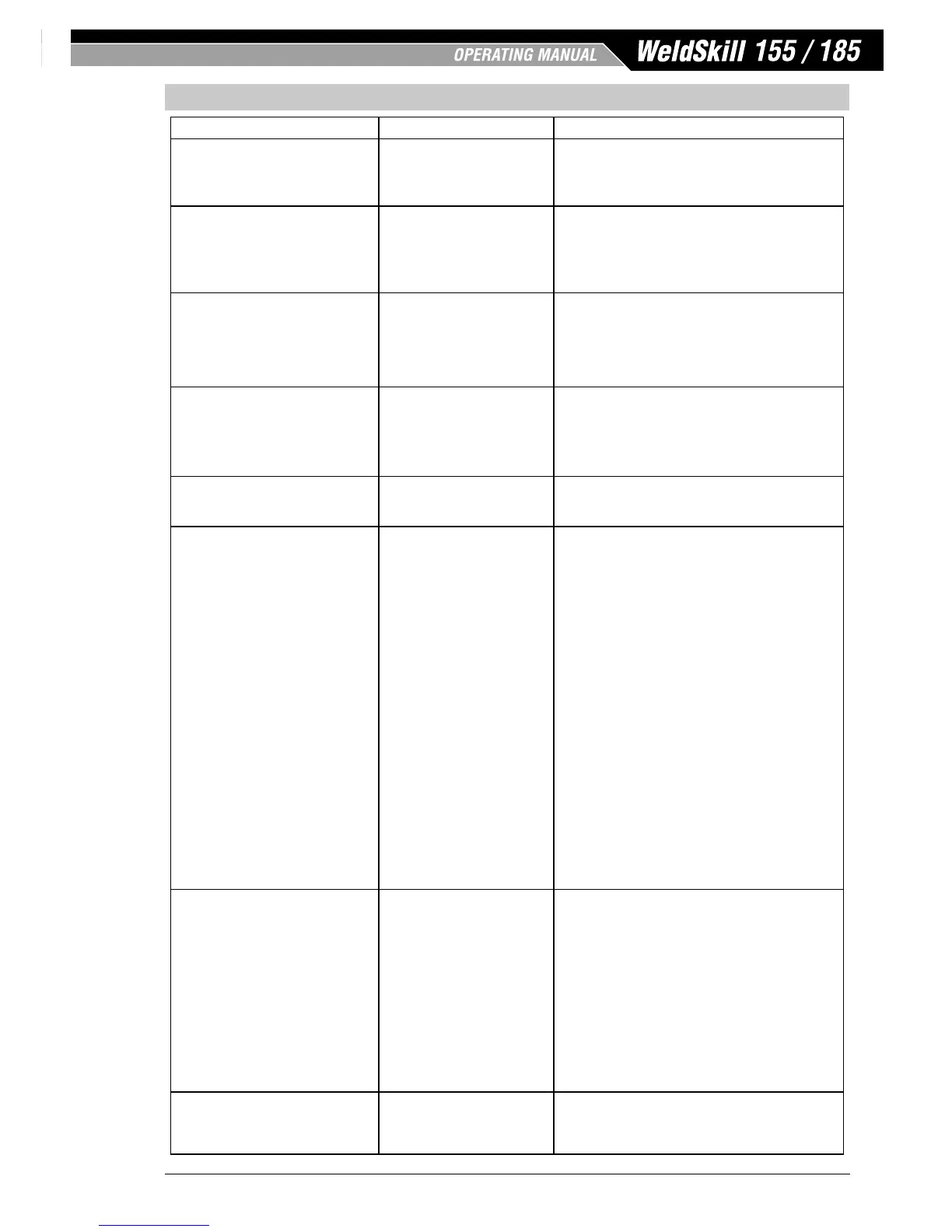

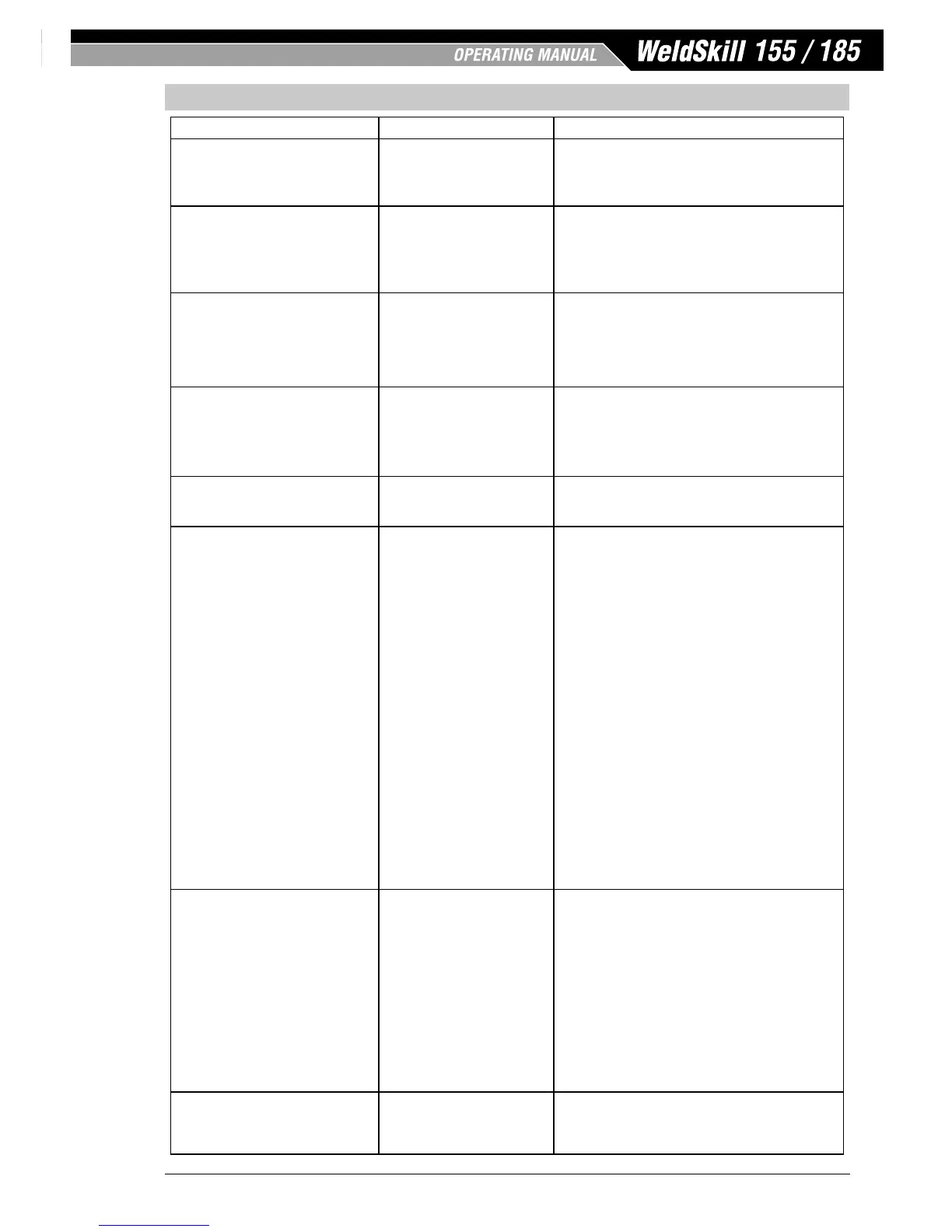

0-5492 7-7 TIG (GTAW) Welding

7.04 TIG (GTAW) Welding Problems

FAULT CAUSE REMEDY

1 Excessive bead build up or

poor penetration or poor

fusion at edges of weld.

Welding current is too

low

Increase weld current and/or faulty joint

preparation.

2 Weld bead too wide and

flat or undercut at edges

of weld or excessive burn

through.

Welding current is too

high

Decrease weld current.

3 Weld bead too small or

insufficient penetration or

ripples in bead are widely

spaced apart.

Travel speed too fast Reduce travel speed.

4 Weld bead too wide or

excessive bead build up or

excessive penetration in

butt joint.

Travel speed too slow Increase travel speed.

5 Uneven leg length in fillet

joint

Wrong placement of

filler rod

Re-position filler rod.

6 Electrode melts or oxidises

when an arc is struck.

A Torch lead connected

to positive welding

terminal.

A Connect torch lead to negative welding

terminal.

B No shielding gas

flowing to welding

region.

B Check the shielding gas lines for kinks

or breaks and shielding gas cylinder

contents.

C Torch is clogged with

dust or dirt.

C Clean torch.

D Shielding gas hose is

damaged.

D Replace shielding gas hose.

E Shielding gas regulator

turned off.

E Turn On Shielding Gas and adjust

Shielding Gas flow rate for the welding

job. Refer to Table 7-5 on Page 7-7.

F The electrode is too

small for the welding

current.

F Increase electrode diameter or reduce the

welding current.

7 Dirty weld pool A Electrode contaminated

by contact with work

piece or filler rod

material.

A Clean the electrode by grinding off the

contaminates.

B Work piece surface has

foreign material on it.

B Clean surface.

C Shielding gas

contaminated with air.

C Check shielding gas lines for cuts and

loose fitting or change shielding gas

cylinder.

8 Poor weld finish Inadequate shielding

gas.

Increase shielding gas flow or check

shielding gas line for shielding gas flow

problems.

Loading...

Loading...