- 9 -

8. CHOICE PARAMETERS OF DRYING

Temperature of drying

Value depends on kind of material. Too low temperature makes

partial evaporation (sample isn’t dried completely). Too high temperature

makes deflagration substance (sample is overheated) or possibility to

appearance chemical reactions. Temperature of drying is given by factory

and trade rules. If there is no rules given temperature can be chosen

experimental.

Time of testing sample

This is range of time [given in seconds] between following

measurements of sample mass. On the basic of this criterion moisture

balance treats sample as dried. Too short time of testing sample makes

fihish of measurement too soon. Too long time of testing sample makes

oscillate around final result. Measurement is finished if 3 following results of

detecting moisture are the same. If time of testing sample is settled on 2s

drying is finished if result doesn’t change in 6 s time. If time of testing is

settled on 20s result has to be the same by 1 minute time to finish drying.

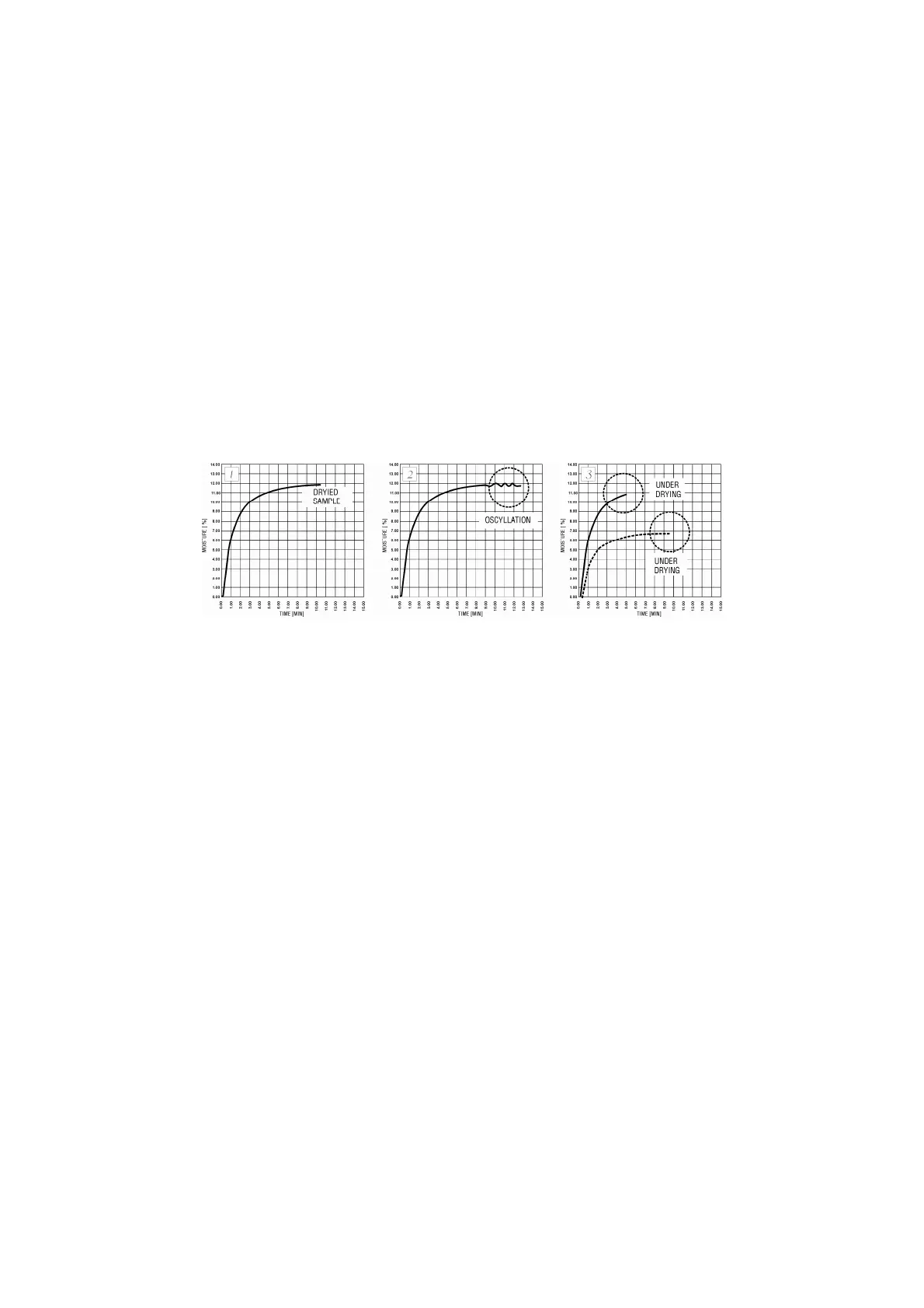

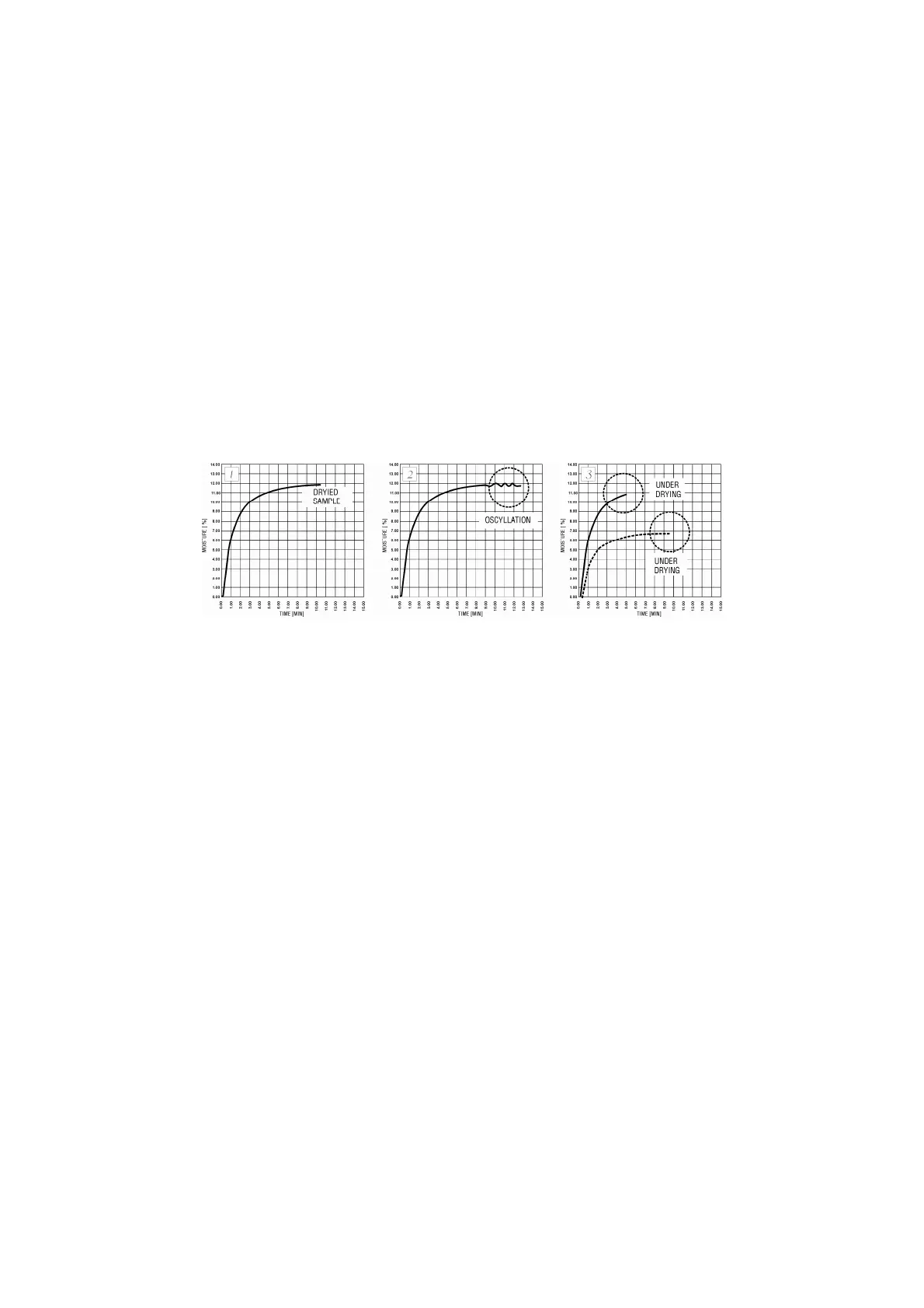

1 – correctly selected drying parameters

2 – too big sample mass or too low temperature of drying or too

short time of drying

3 – disturbances in the drying process or to long time of

sampling

Loading...

Loading...