SM VEHICLES

OVERHAULING AN ENGINE S 100-3 25

ASSEMBLY Contd.

41

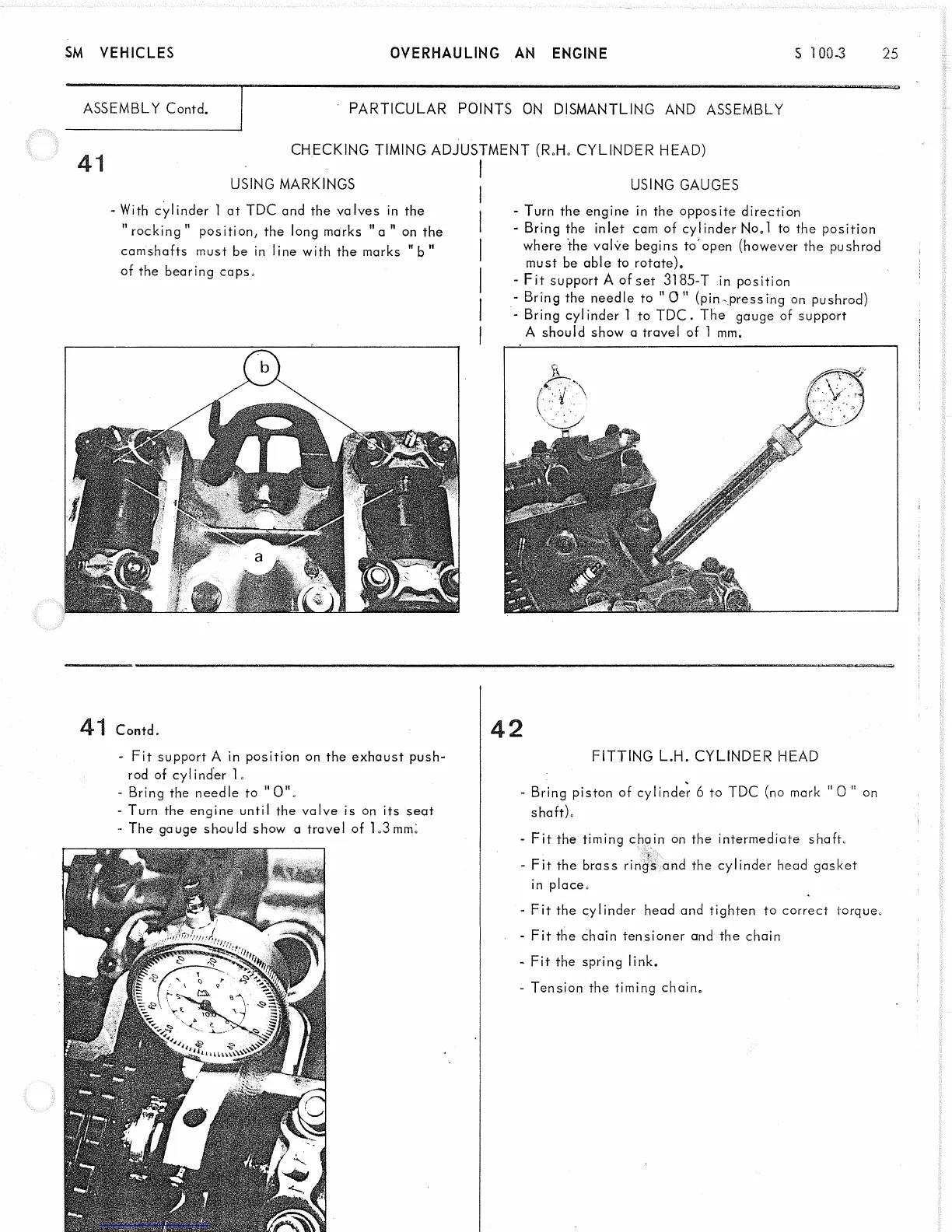

USING MARKINGS

- With cylinder 1 at TDC and the valves in the

"ro ck ing " position, the long marks " a " on the

PARTIC ULAR POINTS ON DISMANTLING AND ASSEMBLY

CHECKING TIMING ADJUSTMENT (R.H. CYLINDER HEAD)

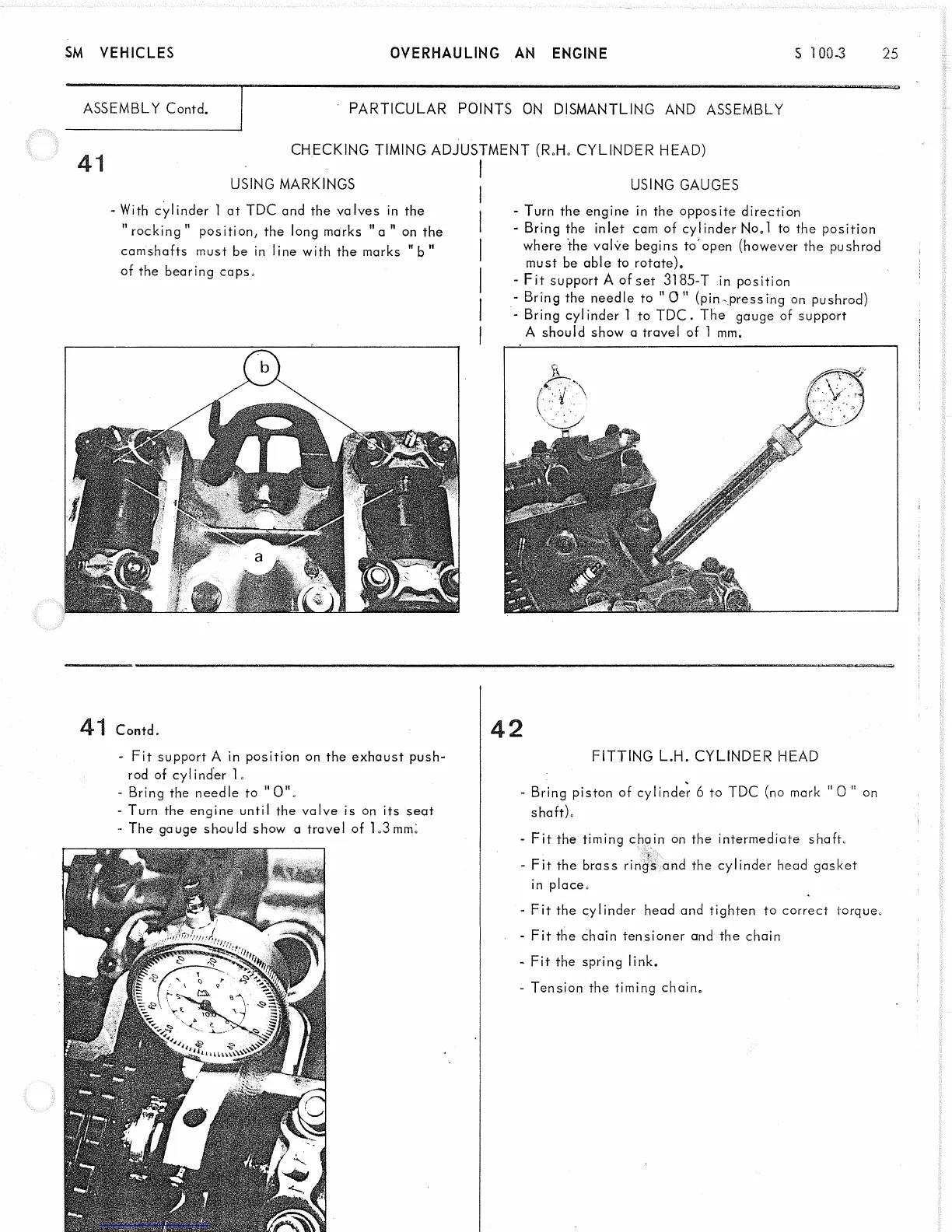

USING GAUGES

camshafts must be in line with the marks

of the bearing caps.

b"

- Turn the engine in the opposite direction

- Bring the inlet cam of cylinder No„l to the position

where the valve begins toopen (however the pushrod

must be able to rotate).

- F it support A of set 3185-T in position

- Bring the needle to " 0 " (pin-pressing on pushrod)

- Bring cylinder 1 to TDC. The gauge of support

A should show a travel of 1 mm.

41 Contd.

- F it support A in position on the exhaust push

rod of cylinder 1«

- Bring the needle to "0"o

- Turn the engine until the valve is on its seat

- The gauge should show a travel of 1.3 mm.

42

FITTING L.H. CYLINDER HEAD

- Bring piston of cylinder 6 to TDC (no mark " 0 " on

shaft).

- F it the timing chain on the intermediate shaft.

- F it the brass rings and the cylinder head gasket

in place.

- F it the cylinder head and tighten to correct torque.

- Fit the chain tensioner and the chain

- Fit the spring link.

- Tension the timing chain.

Loading...

Loading...