Seite 12 von 38

4.4 Componentents

4.4.1 Blast Cabinet

These consists of a stable steel construction and are designed as dust-tight vacuum cabins.

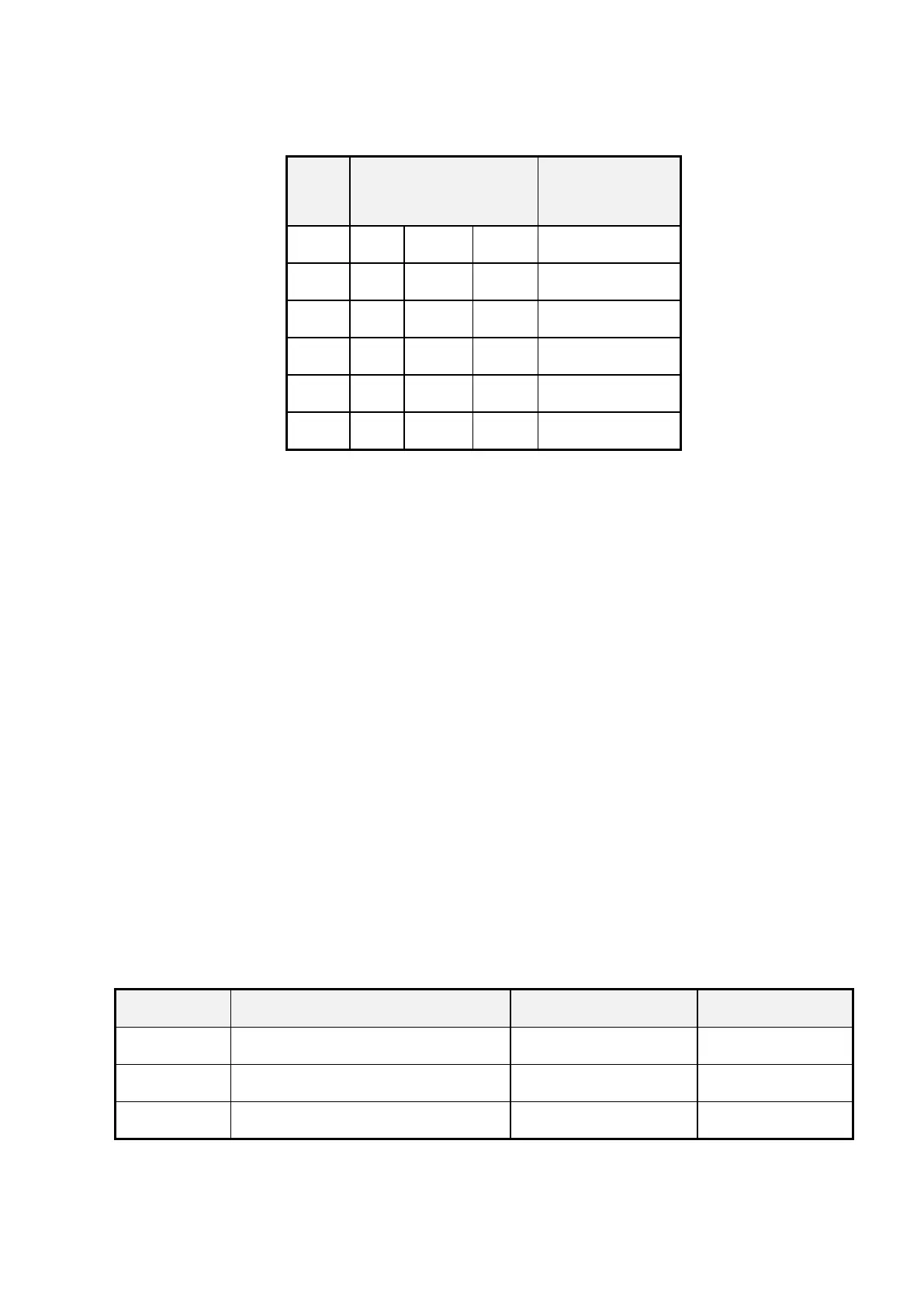

Size Work area

H x B x T[mm]

* Doors divided into two.

Table 1: Standard cabinet types

Doors for bringing in the materials.

Hand holes with adapted work gloves for carrying out the blasting work.

Viewing window for observing the blasting process.

BNP- injector gun.

Extraction hose (dimensions matched to the application).

Blasting room lighting.

Blow-off gun for blowing off dust and blasting media from workpieces

Control and safety devices

ON / OFF switch for blasting room lighting

Foot pedal for switching the blasting process on and off.

Pilot regulator with manometer for controlling the pressure regulator and for setting the jet pressure.

Safety circuit for automatic shutdown of the blasting process if the doors are accidentally opened

prematurely.

4.4.2 Recovery system

See separate owner’s manual.

The size of the cyclone is matched to the size of the cabinet.

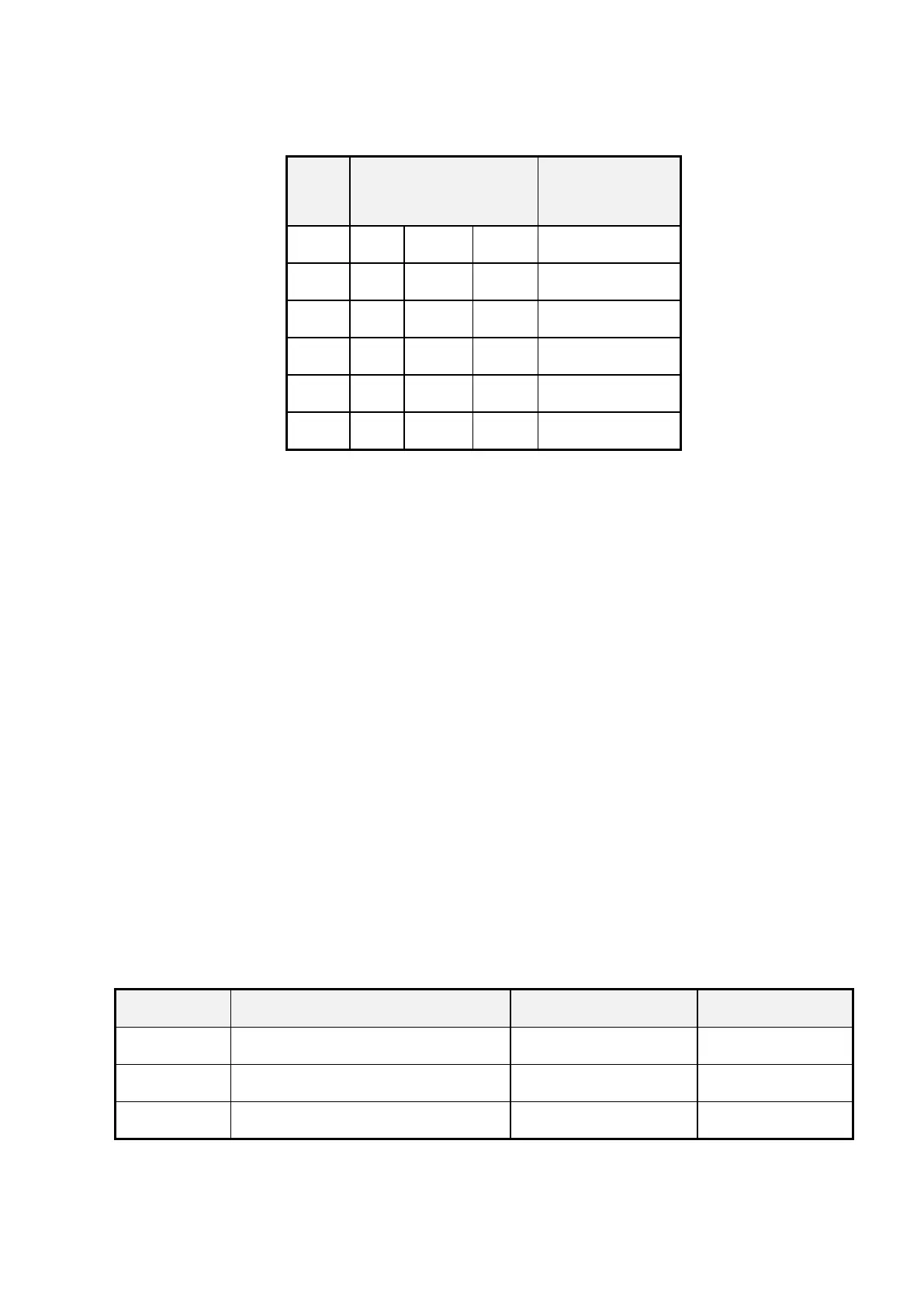

Suction power [m

3

/min.] resp. [cfm]

Table 2: Sizes of abrasive recovery systems

Loading...

Loading...