Revision: 2.1

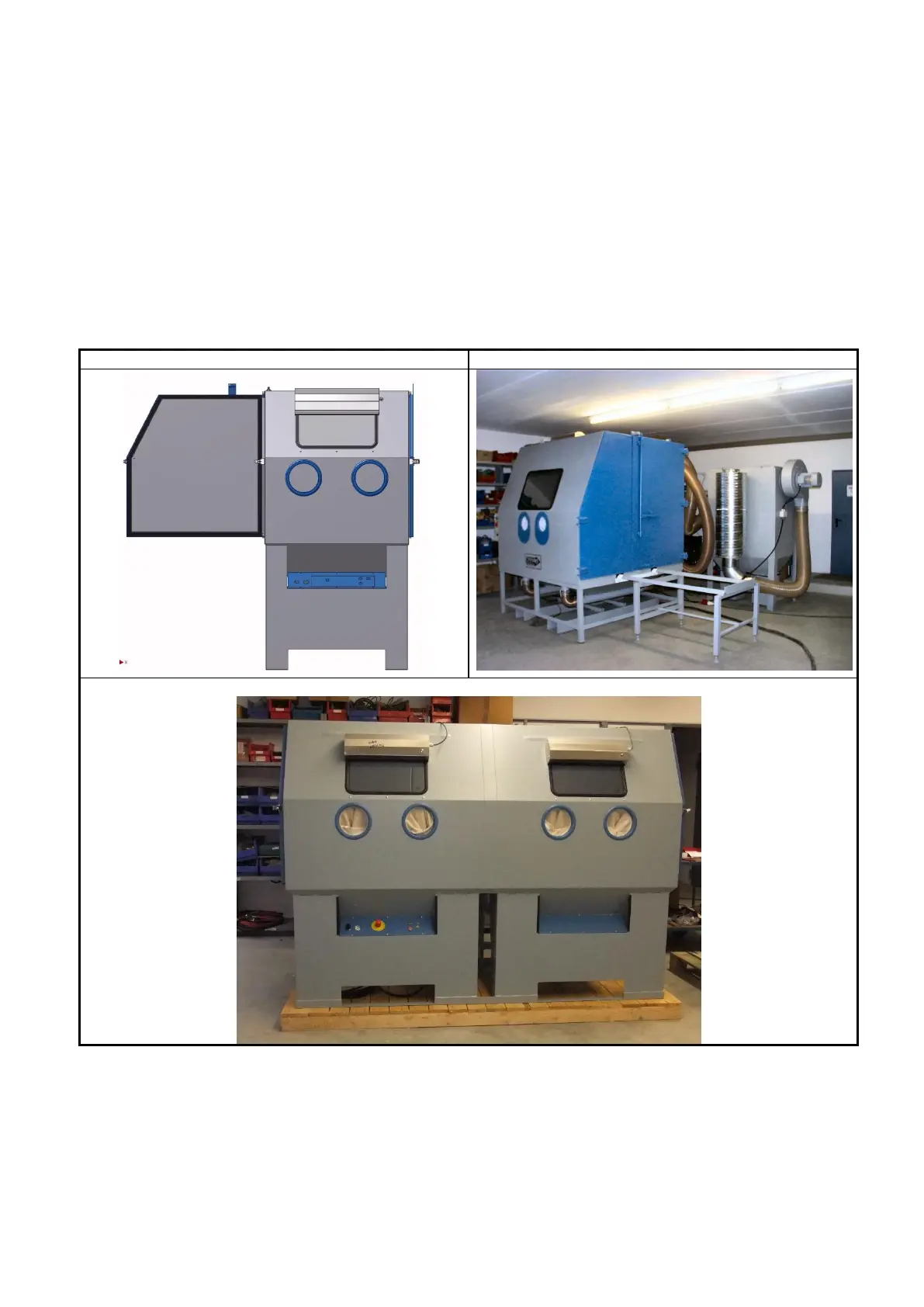

Figure 1 shows the pneumatic circuit of a BNP suction cabinet. The compressed air is fed into the system via a

water separator (item 1), reaches the pilot regulator (item 3) via the air hose and from there to the door safety

valves (item 5). If the foot pedal (pos. 8) is pressed and the cabinet doors are closed (door safety valves pos. 5

released), the control air flows to the pressure regulator (pos. 4) and compressed air flows to the injector jet gun

(pos. 6). The abrasive is sucked out of the cleaner (reclaimer) with the abrasive hose and the blasting process

begins. The desired pressure is set with the pilot regulator (item 3).

If the foot pedal is released, the blasting process is interrupted. This is also interrupted when the doors are opened

(door safety valve pos. 5 closes).

The contaminated blasting media in the hopper floor of the blasting cabinet is sucked into the recovery system by

the fan and cleaned using the cyclone principle (see picture for arrangement). The light impurities (dust) are

transported with the air flow to the dust filter, the heavy particles fall down into the cyclone, whereby the oversized

particles are caught with a coarse sieve. This completes the cycle.

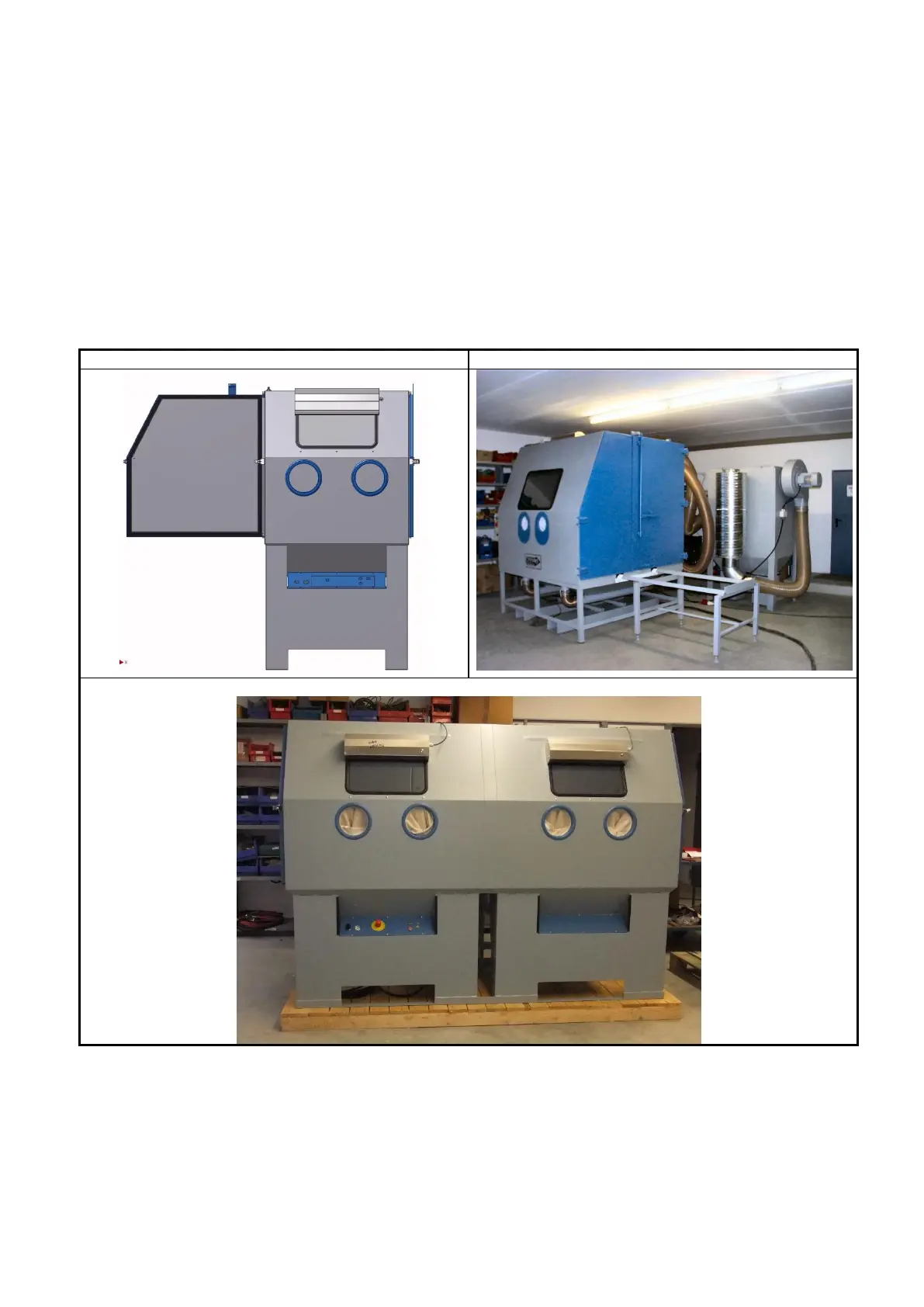

3.4 Description

3.4.1 Media-recovery system (Cyclone)

- Cyclone principle

- Deposition of:

o Dust in dust collector

o Good media in circuit

o Coarse impurities in screen

Loading...

Loading...