Tranquility

®

Digital (DXM2)—Troubleshooting Guide

Rev.: 10 March, 2015

16

Geothermal Heating and Cooling

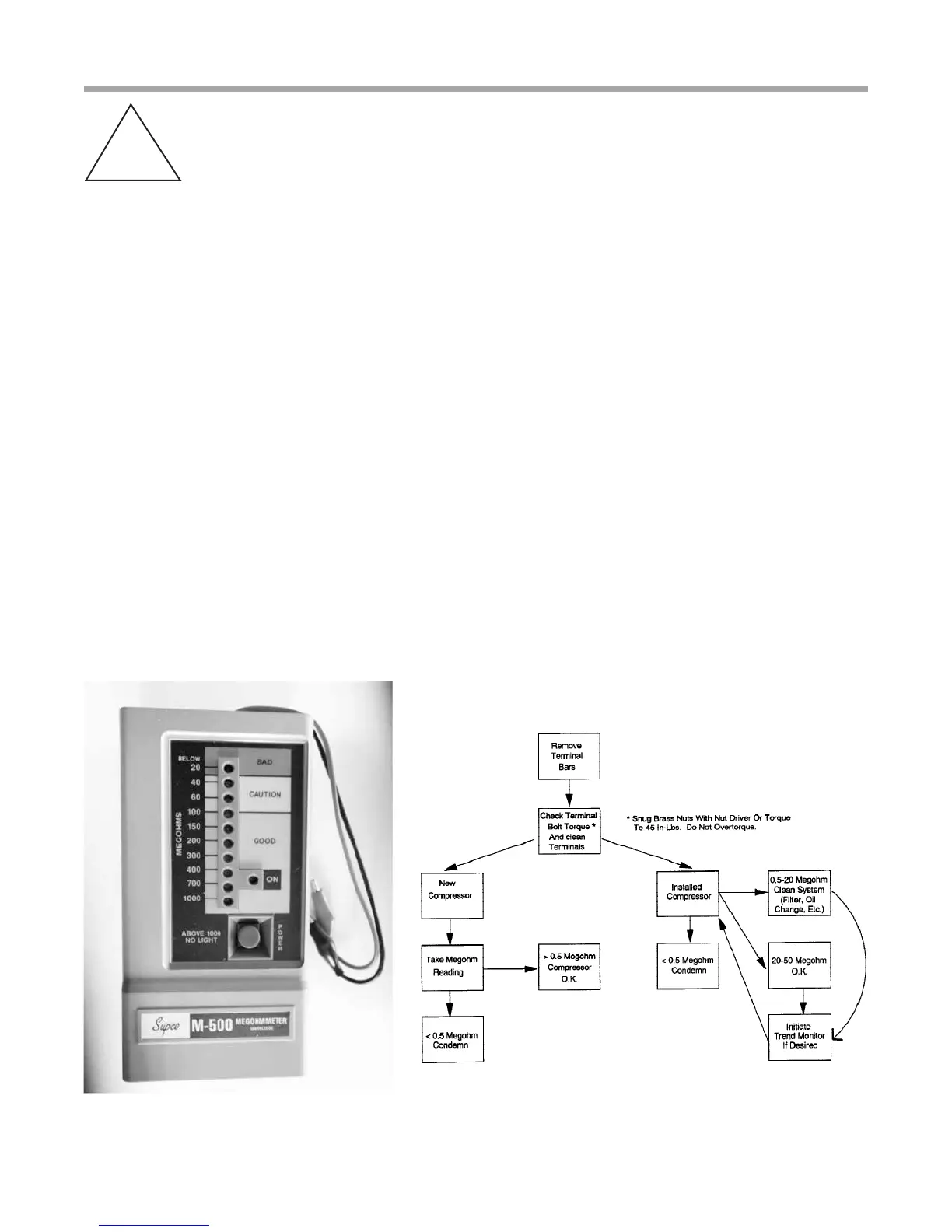

An Alternative Way of Checking Compressors

A-D

Megohm Values of Copeland Compressors

For years servicemen have used megohmeters to evaluate

compressor motor windings. However, most megohmeter

manufacturers publish guidelines that apply to open motors.

For this reason, Emerson Climate Technologies has

investigated the use of megohmeters on hermetic and semi-

hermetic compressors.

When using megohmeters to evaluate the motor insulation

of compressors, it is important to understand that they

should not be used as one would a volt-ohm meter. A single

megohmeter reading gives little insight into the condition of a

motor’s insulation.

Megohmeters are best used as a part of a regular

maintenance program to monitor trends (over several

months). For example, one might record a megohm value

and compare it to a previous reading. If subsequent readings

show a trend of lower and lower values, then corrective

action (such as system clean up) should be taken.

Emerson does not incorporate the megohmeter into any of

its quality checks. All Copeland® compressors must pass

U.L. required tests using hi-potential current leakage testers

(“hi-pot”). Studies performed by Emerson have found that

compressors with megohmeter readings as low as 0.5

megohms still pass the hi-pot.

There are many factors that affect megohm readings

including contaminated refrigerant, oil level, refrigerant in

oil and current leakage through electrical fusites or terminal

plates.

Any external electrical components connected to the

compressor terminals also affect megohm readings. Wires,

contactors and relays all leak current and will decrease

compressor megohmeter readings if not disconnected.

As mentioned earlier a single megohm reading cannot be

used to condemn a compressor since many other factors are

involved. However, limits can be placed on megohm values

that dictate action be taken. Emerson has found that these

limits are related to the rated voltage of the compressor.

Megohm values equal to or greater than 1000 ohms per volt

are probably acceptable. For example, a 460 volt compressor

might show a megohm reading of 460,000 ohms or 0.46

megohm. Compressors with rated voltages of 208 to 230

volts would then be operable at megohm values of 0.208 to

0.230 megohms; for simplicity, Emerson has set the limit at

0.5 megohms before a compressor is condemned. Figure 1

shows the required procedure for checking compressors with

a megohmeter.

New compressors that have never been installed will not

need any system clean-up procedures so long as the

megohm reading is above 0.5. A baseline reading must be

established for comparison purposes and since this is its rst

reading this will be its baseline value.

Megohmmeter

2

© 2010 Emerson Climate Technologies

Printed in the U.S.A.

AE4-1294

Application Engineering

BULLETIN

Figure 1

Megohmeter Test Procedure

Loading...

Loading...