36 WDAT-SL3 FC 200.2-580.2 M08S40E15-01

8.12 Screw compressors - Periodical checks

Operating hours 100 1000 5000 10000 15000 20000 25000 30000

Vibrations / Noise CCCCCCCC

Oil level CCCCCCCC/R

Oil lterCCCCC/R

Filter the suction C C C C

Electric insulation CCCCCCC

Bearings C/R

check valve CCCCCCC

C = CHECK

R = replace

NO PUMP-DOWN !

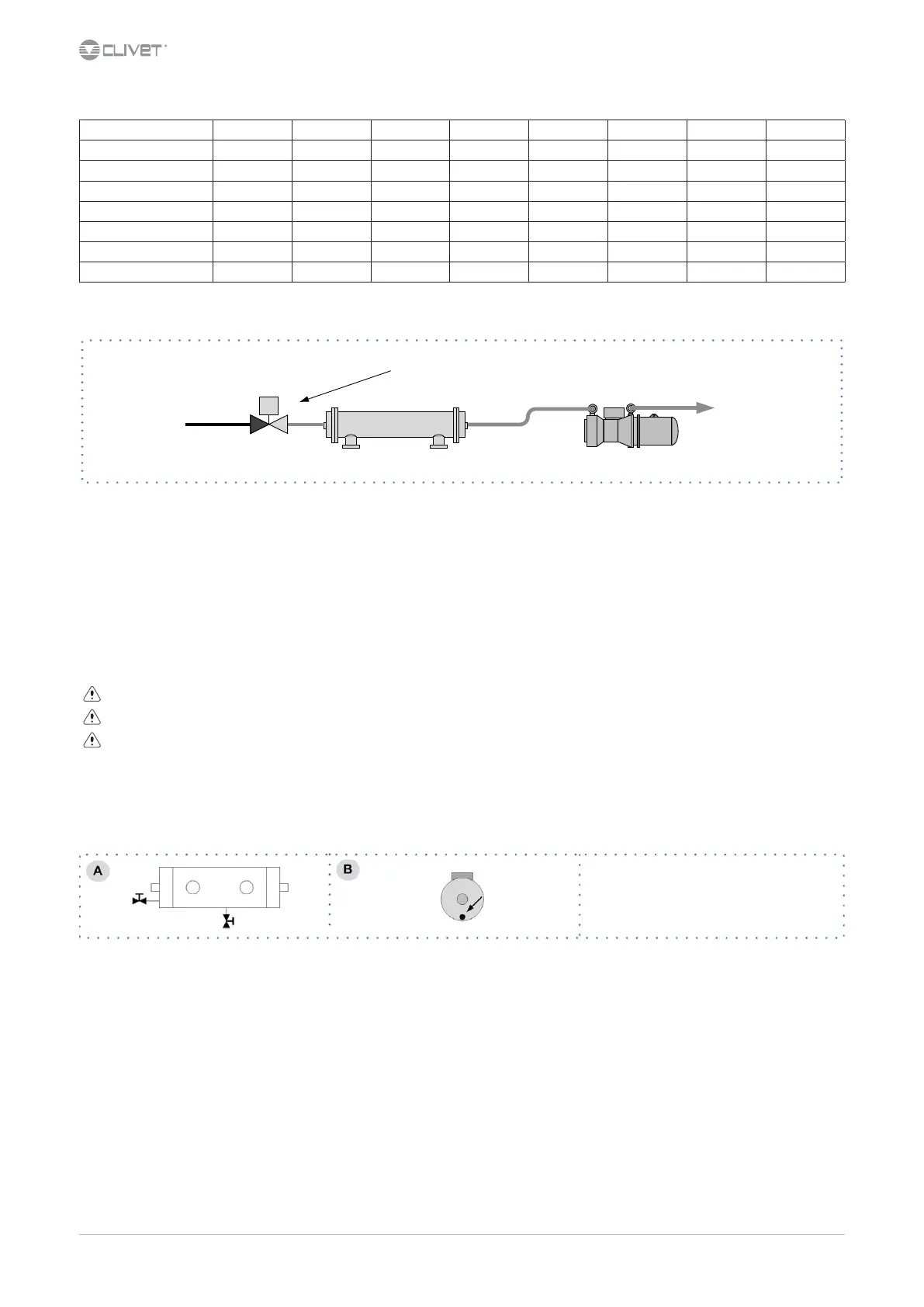

8.13 System discharge

1. evacuate the system

2. It is possible to limit the absorbed electric power with an external signal 0-10 Vcc or 4-20mA.

3. evacuate the exchanger, use all the cocks presents

4. use compressed air to blow the exchanger

5. dry completely the exchanger by an hot air jet; for greater safety ll the exchanger with glycoled solution

6. protect the exchanger from the air

7. remove the drain plugs to the pumps

Any anti-freeze liquid contained in the system should not be discharged freely as it is a pollutant.

It must be collected and reused.

Before starting a washing the plant.

Example

A. emptying evaporator

B. emptying pump

It’s recommended that the re-start after the stopping period is performed by a qualied technician, especially after seasonal stops or seasonal

switching.

When restarting, refer to what is indicated in the “start-up” section.

Schedule technical assistance in advance to avoid hitches and to guarantee that the system can be used when required.

8.14 Insulations

Check the condition of the insulations: if necessary apply glue and and renew the seals.

Loading...

Loading...