Click to go to Top of Document

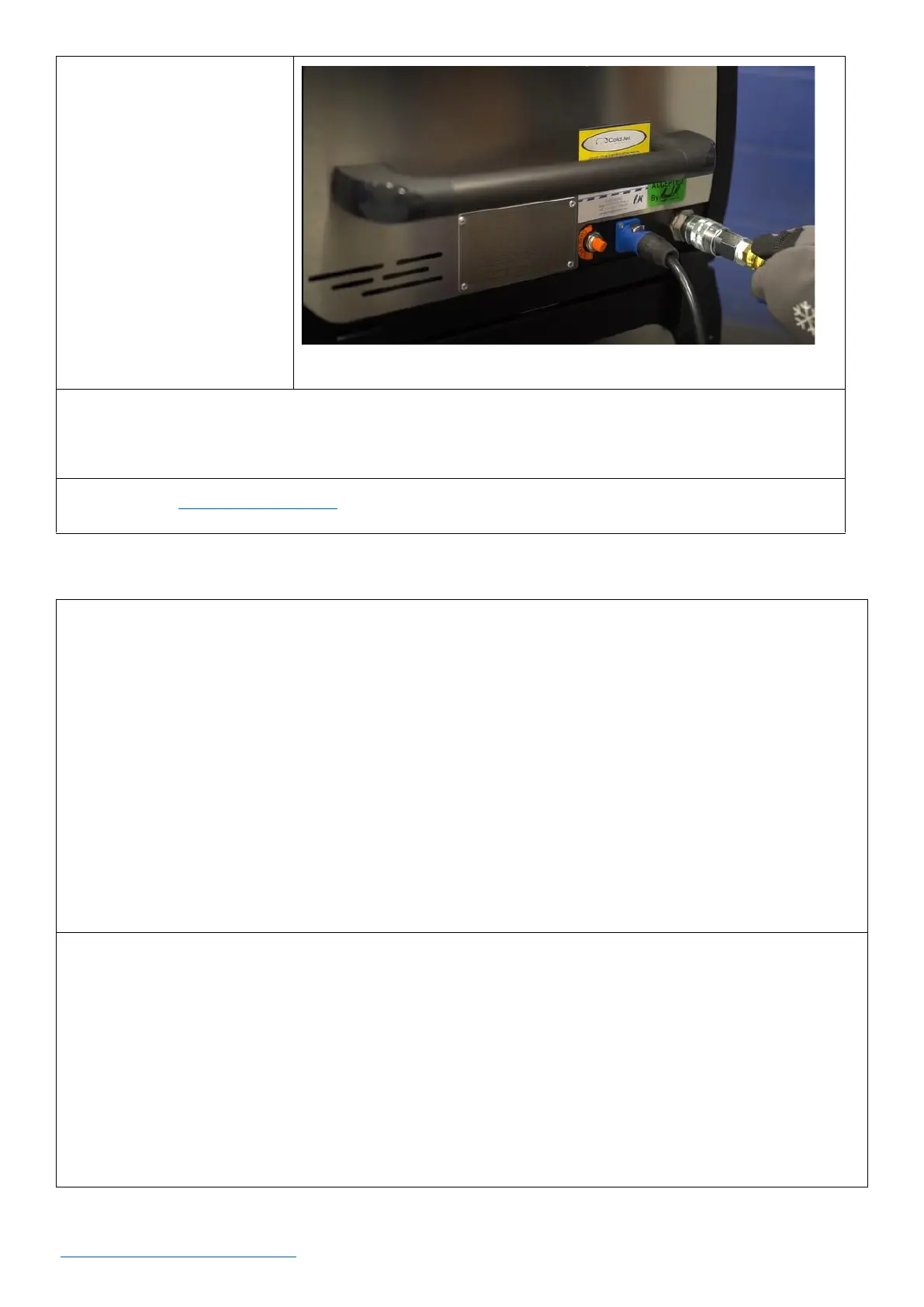

8. Attach the air supply

hose to the port on the

right side.

NOTE: The machine

comes with a ¾ in (19

mm) claw coupling in the

drawer of the cabinet to

use with larger diameter

air hoses.

9. Turn the air supply on and allow the air hose to pressurize.

• NOTE: Maximum air supply pressure should not exceed 145 psi (10 bar)

10. Go to the Starting the Machine section of this manual.

The Compressed Air Supply

• Although Cold Jet dry ice equipment is designed and engineered to work under the most

demanding environments and conditions, the incoming air supply must be as free of oil,

dirt/foreign particles, and water/moisture as possible.

o For example, oil-laden air will contaminate the entire system including any articles being

dry ice blast cleaned.

• Contaminants such as dirt/foreign particles will score or even clog interior mechanical parts

resulting in poor machine function.

• Dirt/foreign particles in the compressed air can strike the article causing damage to the surfaces

being dry ice blast cleaned.

• The results of frozen water and/or moisture can be:

o “Water-ice” - It is a very good adhesive; internal parts may freeze together and seize the

machine.

o Loose water-ice pieces could build up and cause clogs in the hose, particle control

assembly, feeder and/or nozzle.

o Water-ice is harder than dry ice and may cause damage to the article being dry ice

cleaned.

Loading...

Loading...