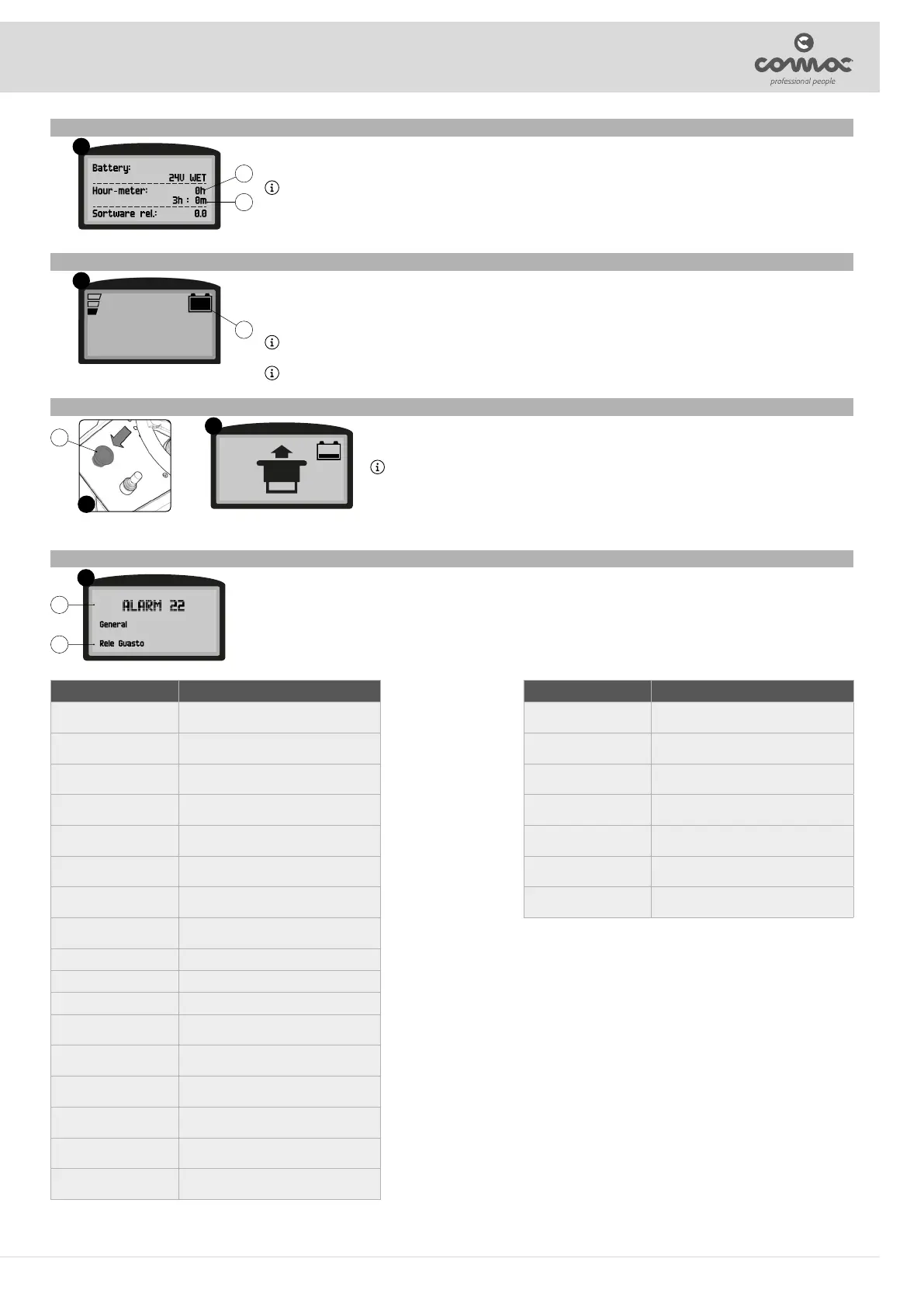

HOUR METER

Through the control display, in the screen after switching on, it is possible to view the hours of work performed by the machine in the central part of the

screen (Fig. 15).

In the rst line indicates the total use time of the machine (12) and the second line indicates the partial use time of the machine (13).

N.B.: The numbers followed by the letter “h” identify the hours, while the numbers followed by the letter “m” identify the tenths of an hour (a tenth of

an hour corresponds to six minutes).

15

12

13

BATTERY CHARGE LEVEL INDICATOR

The machine's control panel contains the control display. At the top right of the work screen, there is a graphic symbol (14) representing the battery charge

level indicator (Fig. 16).

The indicator is composed of 5 charge levels, each of which represents about 20% of residual charge. With a residual charge of 20% the graphic symbol

starts to ash and after a few second it will appear in larger dimensions in the middle of the screen, under these conditions take the machine to the usual

place to charge the batteries.

N.B.: A few seconds after the battery charge level reaches 20%, the brush motors switch o automatically. With the remaining charge it is possible

to complete the drying process before starting the recharge.

N.B.: A few seconds after the battery charge level reaches 10%, the vacuum motor switches o automatically. With the remaining charge, it is still

possible, however, to move the machine to the location designated for its recharging.

16

14

EMERGENCY BUTTON

if there are any problems while you are working, press the emergency button (15) on the control panel (Fig. 17). This function

interrupts all functions active at that moment, in this way both the brush head body and the squeegee body will rise from the

oor and automatically switch o with the expected delays.

N.B.: As soon as the emergency button (15) is pressed, the dedicated symbol appears on the control display (Fig. 18).

Once you have stopped the machine and solved the problem, to resume work proceed as follows:

1. Turn the main machine switch to “0”, turn the key a quarter turn anti-clockwise.

2. Move the emergency switch (15) to the resting position, turn the switch one forth of a turn to the right (as indicated by the

arrows engraved in it).

3. Turn the main machine switch to “I”, turn the key a quarter turn clockwise.

17

18

15

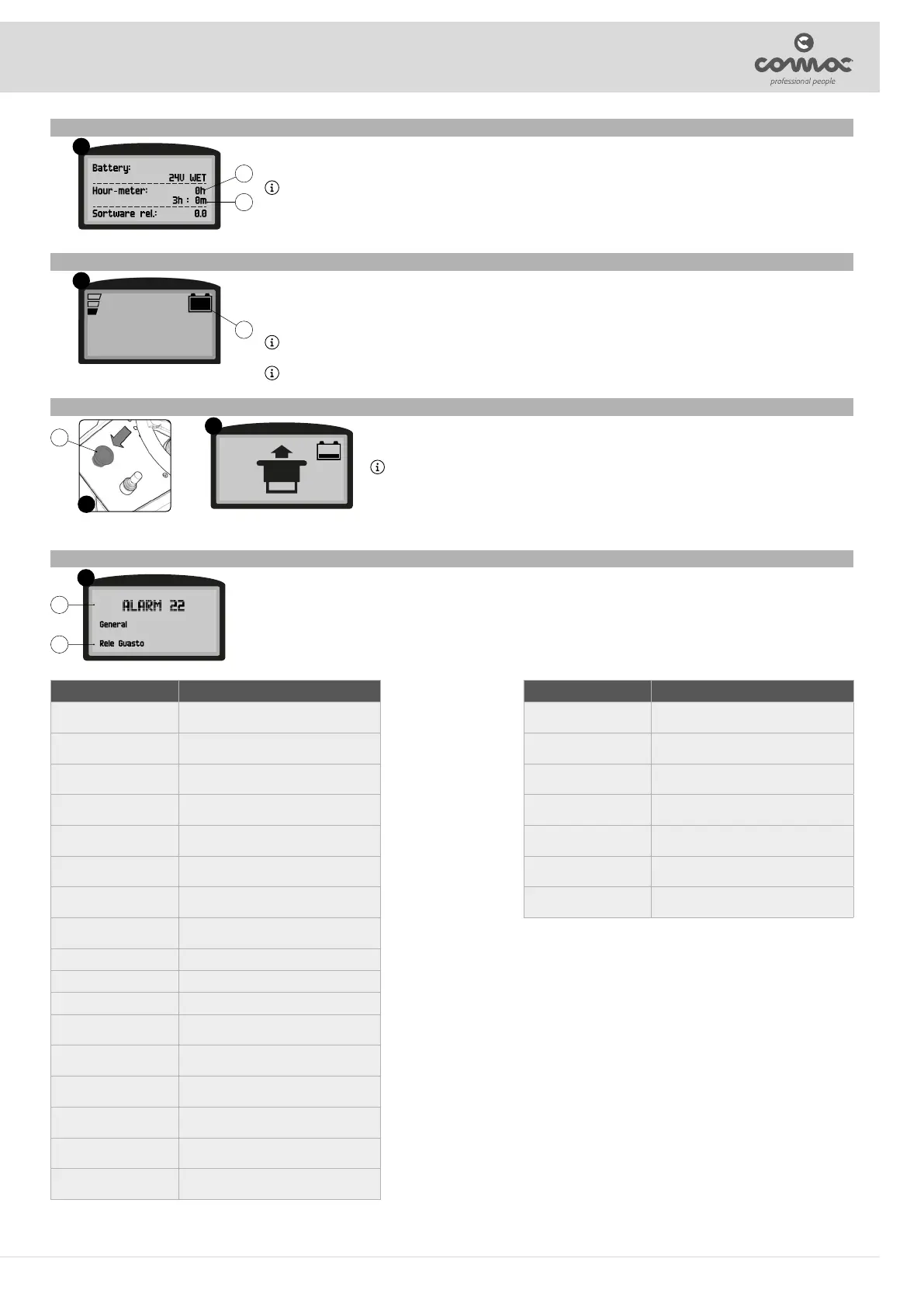

ALARM SCREEN

When an error occurs, the corresponding alarm screen (Fig. 19) will appear on the control display.

The display of the alarm consists of a rst ashing line relating to the code (16) and the source of the error (17) (Fig. 19), while in the second line displays a

summary (18) of the error description.

19

16

17

ALARM #id MEANING

AL_1: Function

Brushes Overcurrent.

Brushes overload protection

AL_2: Function

Vacuum cleaner overcurrent

Vacuum cleaner amperometric protection

AL_3: Function

Power Board Damaged

Damaged power stage

AL_4: Function

Overcurrent

Overcurrent on brush or vacuum cleaner outputs

AL_5: Function

Overtemperature

Thermal cut-out protection on the brushes -

vacuum cleaner stage

AL_8: Function

Act1: time-out

Brushes actuator: nal position not reached

AL_9: Function

Act2: time-out

Squeegee actuator: nal position not reached

AL_12: Traction

Generic AL.

Undervoltage

Overvoltage

Key o

EEprom alarm

AL_13: Traction

Pedal Faulty

Pedal jerking

AL_14: Traction

Pedal Pressed

Pedal pressed at startup

AL_15: Traction

Overtemperature

Thermal cut-out protection on traction stage

AL_16: Traction

Power Board Damaged

Traction power stage damaged

AL_17: Traction

Overcurrent

Overcurrent on Traction output

AL_18: Traction

Amperometric protection

Traction amperometric protection

ALARM #id MEANING

AL_19: Traction

PW stage relay

Traction - Fuse power stage damaged

AL_20: General

Memory Error

Error reading internal memory

AL_21: General

Issue with Key

Key sequence incorrect

AL_22: General

Relay Faulty

General relay damaged

AL_23: General

Overvoltage

Overvoltage

AL_25: General

Button conn.

No dashboard-function communication

AL_26: General

RX-TX Traction

No traction-function communication

21

Loading...

Loading...