2-4 I Description

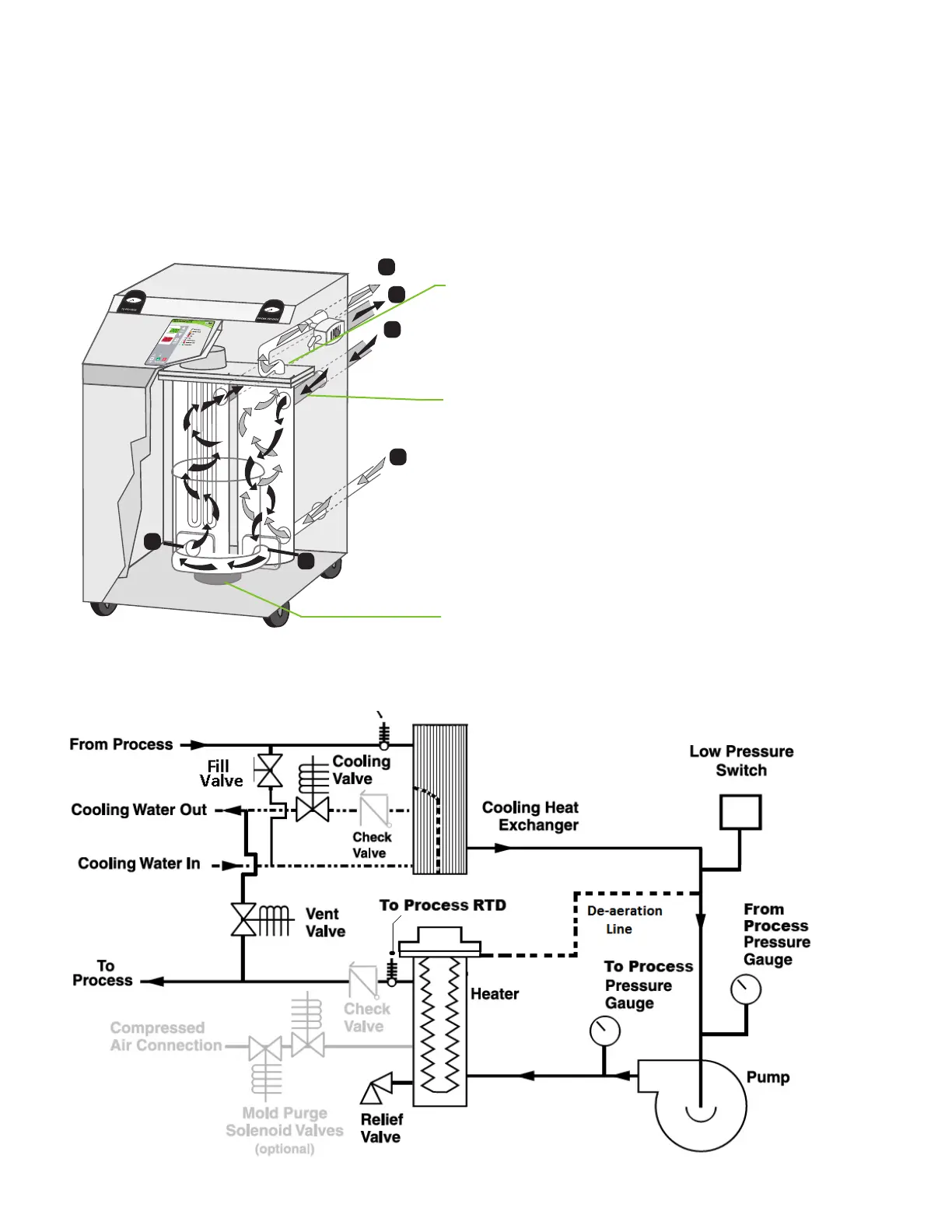

How the Closed Circuit Works

Closed Circuit models maintain the process temperature by electrically heating and indirectly

cooling fluid in the process circuit. Cooling water supplied by a chiller, tower or other water source,

is mixed with the process fluid only during the initial filling or when water is needed to make up

process fluid loss. A brazed-plate heat exchanger replaces the mixing tank used on direct injection

units.

1 The temperature of the process fluid is measured as it

leaves the unit’s heater tank. The fluid then flows through

the “To Process” line A to the mold or process. The fluid

returns to the unit through the “From Process” line B for

reheating or cooling.

2 If the temperature is above the setpoint value, the cool-

ing valve opens. Cool water enters the heat exchanger

via the “Cooling In” line. Process fluid is always being

circulated through the process side of the heat exchanger.

The process fluid is indirectly cooled via conduction from

the colder water now running through the cooling side of

the heat exchanger. If the measured temperature is below

the setpoint, the heater elements inside the heater tank are

energized.

3 The pump moves water from the heat exchanger to the

heater tank. Pressure is measured before and after the pump

with pressure gauge E and F.

D

A

B

C

E

F

TW-S Closed Circuit

Optional From Process RTD

Loading...

Loading...