Appendix I E-1

External Interfaces

Analog Remote Setpoint / Process Temp Retransmit

Connecting to the Thermolator

WARNING: Improper installation, operation, or servic-

ing may result in equipment damage or personal

injury.

External analog signals must be fully isolated from ground. Be sure to use fully

isolated analog channels and/or power supplies. Analog wires must not be

common or referenced to earth ground! Failure to heed this requirement will

permanently damage the analog circuits in the TCU.

Setting the Jumpers

See the table below for the proper jumper position. These jumpers are also shown on

sheet 4 of the electrical print.

Wiring the circuit

Sheet 4 on the electrical print illustrates the proper way to wire the remote interface. You

can choose either 4-20mA or 0-10VDC, not both simultaneously.

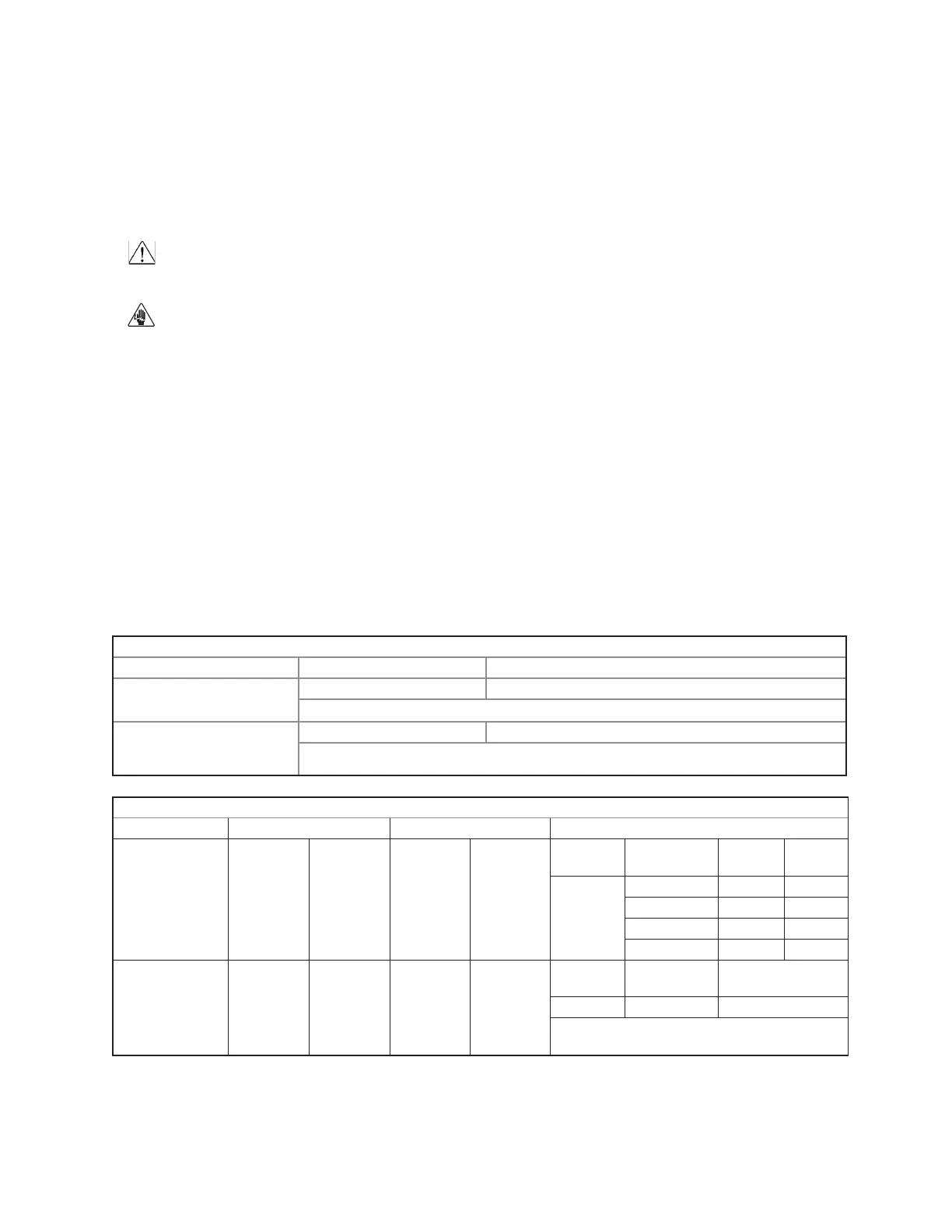

Circuit Impedance Requirements

0-10VDC 4-20mA

Remote Temperature Setpoint

(Input)

11kΩ internal controller impedance. 50Ω internal controller impedance.

NOTE: Voltage or loop current source must be supplied by the external interface.

Process Temperature Retransmit

(Output)

1kΩ minimum external impedance. 500Ω maximum external impedance.

NOTE: Voltage or loop current is self-generated by the TCU’s temperature controller.

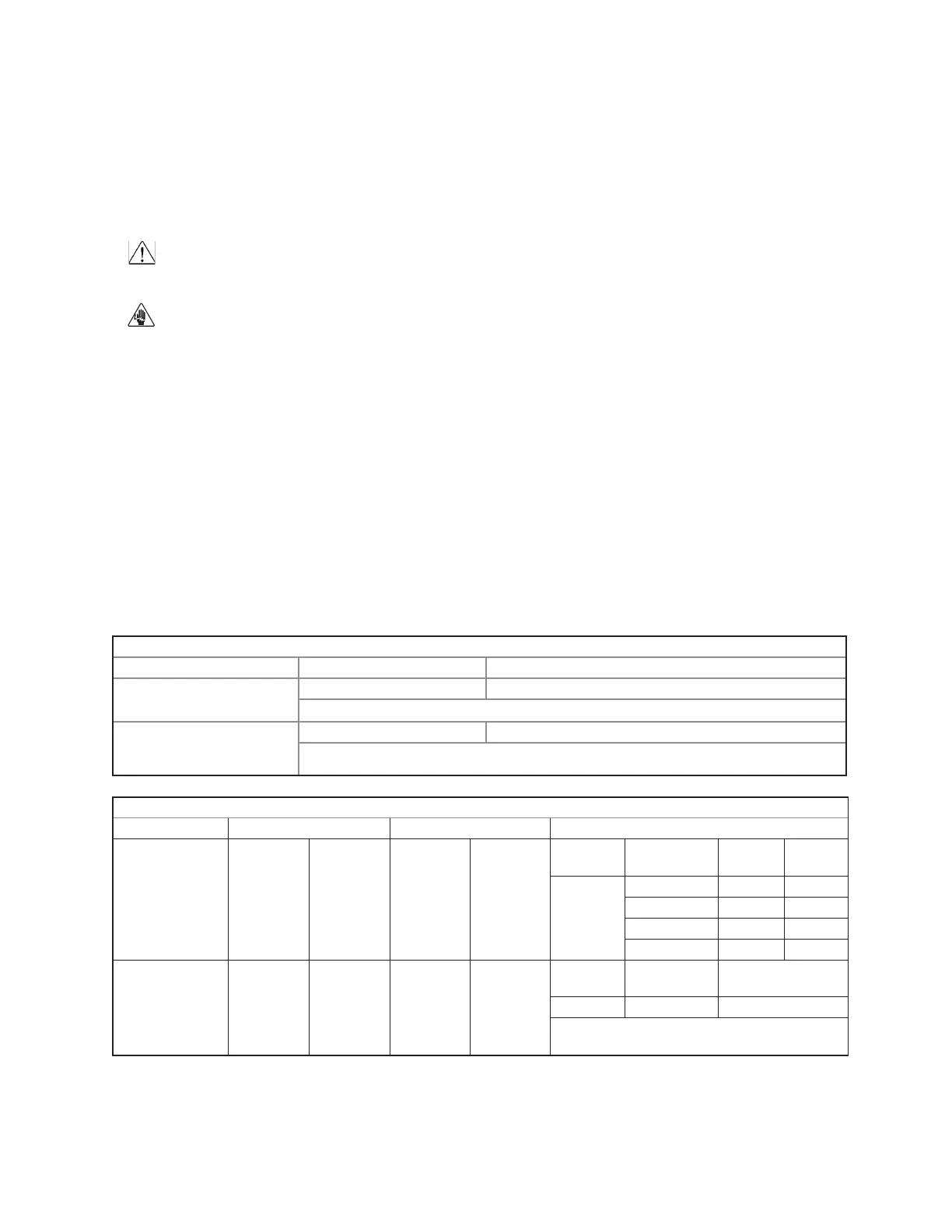

Terminal Wiring / Jumpers

0-10VDC 4-20mA

Remote Temperature

Setpoint (Input)

+

Terminal 255

-

Terminal 254

+

Terminal 255

-

Terminal 254

Analog Input Jumper Number Placement

(4-20mA)

Placement

(0-10V)

Input #4

J1-9 & J1-10

JMP10 OUT OUT

JMP11 OUT IN

JMP13 IN IN

JMP22 IN OUT

Process Temperature

Retransmit

(Output)

+

Terminal #5

on 10-pin

analog output

daughter card

-

Terminal #6

on 10-pin

analog output

daughter card

+

Terminal #3

on 10-pin

analog output

daughter card

-

Terminal #4

on 10-pin

analog output

daughter card

Jumper

Number

Placement (4-

20mA)

Placement (0-10V)

JMP1 Pins 2 & 3 Pins 1 & 2

For 0-10VDC operation, pins 3&4 must be connected

together with an external jumper.

See electrical print sheet 5 for terminal block locations.

(continued)

Loading...

Loading...