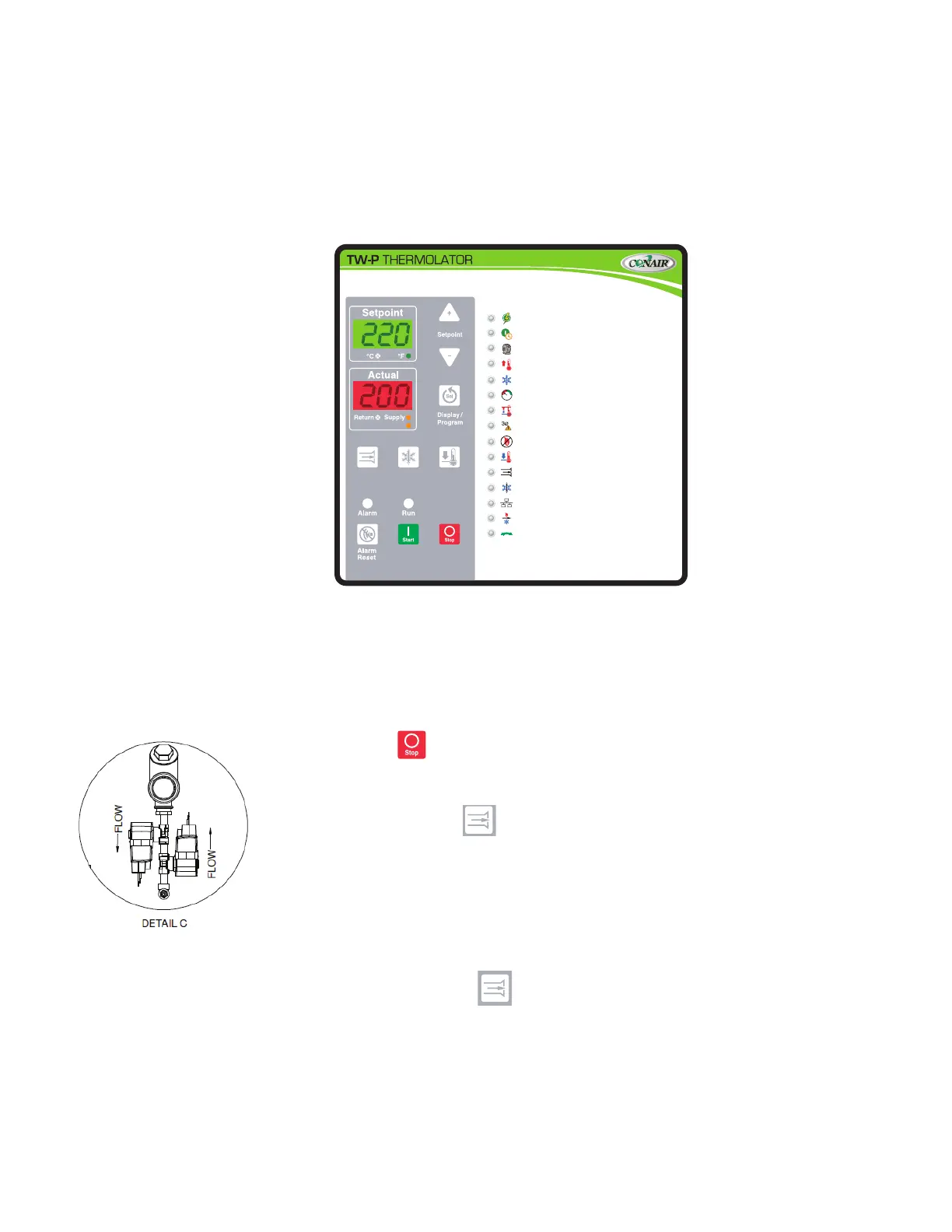

4-20 I Operation

Using the Optional Mold Purge Option

Only the TW-P Thermolator can be ordered with an optional purge valve (Mold Purge),

which clears the process lines of fluid using compressed air. The valve is operated by an

optional manual purge button on the control panel.

IMPORTANT: Before purging the process lines, be sure that the cooling water

source feed is closed. If the feed is open and the air line has a higher pressure

than the cooling water, air may be injected into the cooling water system. If the

cooling water pressure is higher than the air line, cooling water may be injected

into the air line.

1 Press STOP to stop the Thermolator.

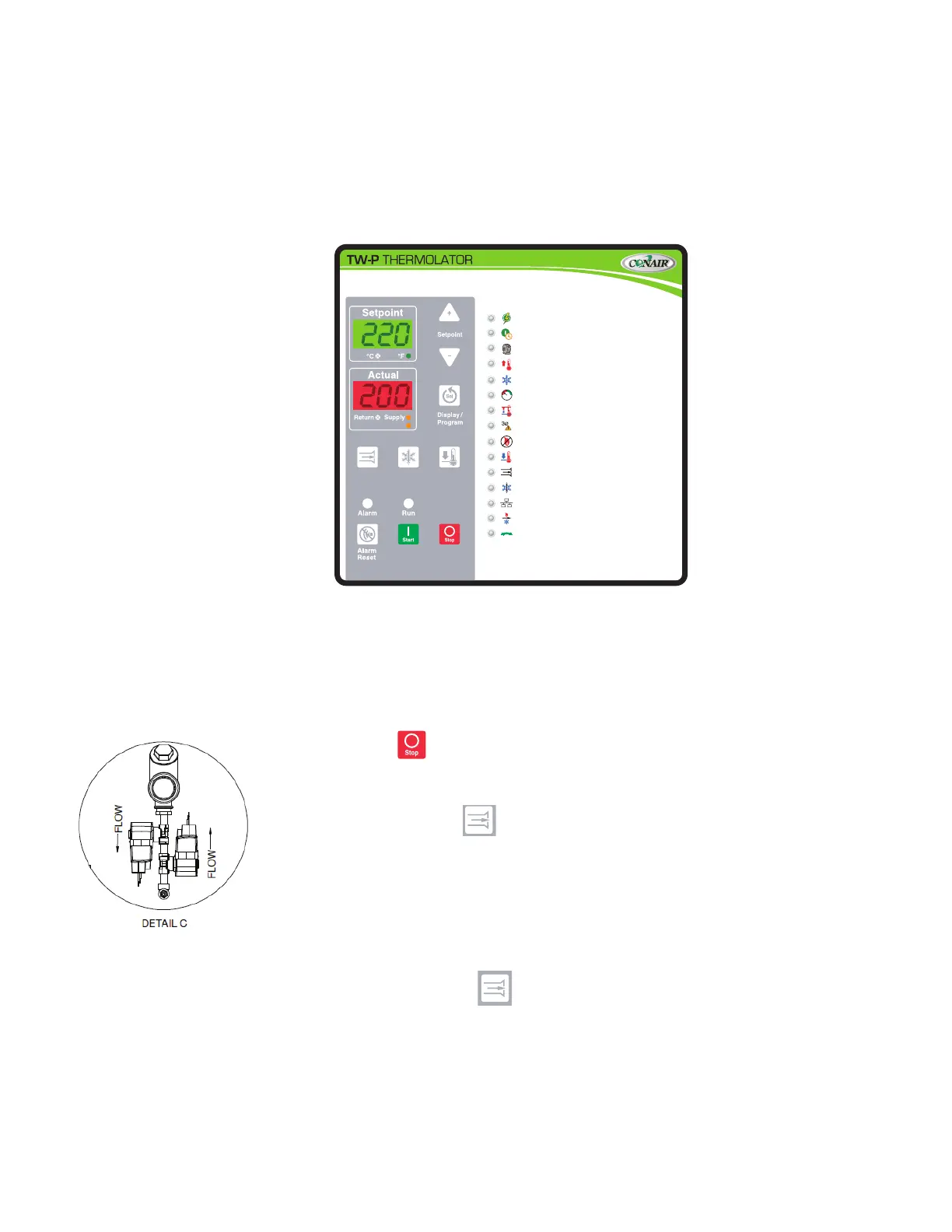

2 Shut off the cooling water supply valve.

3 Press MOLD PURGE

to start purging.

• The “Purge” LED lights.

• The cooling valve is opened.

The time required to clear the process lines of fluid will vary according to the length of the

process piping and the size of the tooling.

4 Release MOLD PURGE

to stop purging.

Mold

Purge

Rapid

Cool

Process

Cool Down

Control Power

Autostart Signal

Pump

Heat

Cool

Coolant Pressure

Temperature Limit

Electrical Phase Error

Heat Error

Process Cool Down

Rapid Cool

Communications

Remote Heat/Cool

Program Mode

Mold Purge

Flow GPM (flash)

Loading...

Loading...