3. WORK TABLE AND MOTOR

3. WORK TABLE AND MOTOR

• Work Table

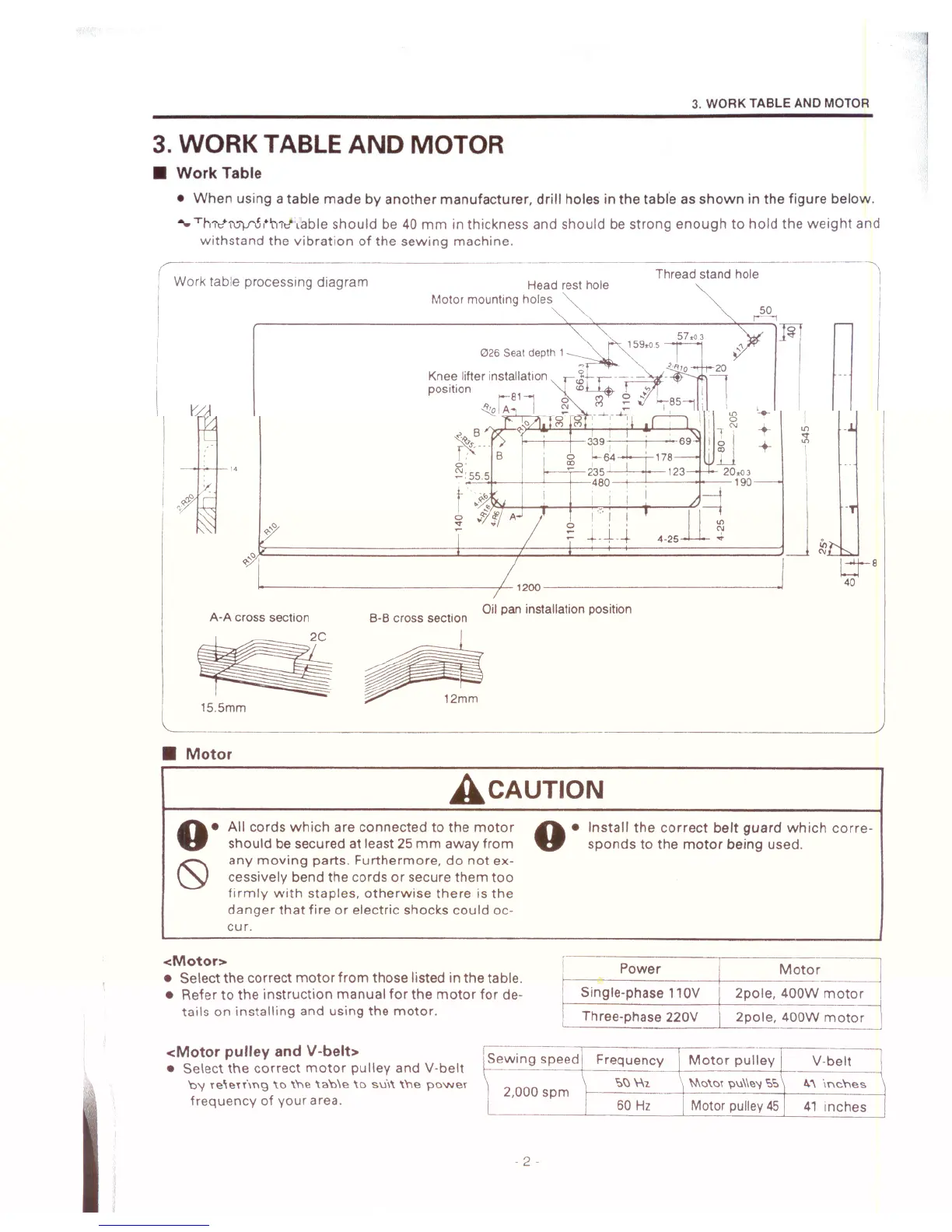

• When using a table made by another manufacturer, drill holes in the tabfe as shown in the figure below .

• The top of the table should be 40 mm in thickness and should be strong enough to hold the weight and

withstand the vibration of the sewing machine.

Head rest hole

Motor mounting holes

w8

40

Thread stand hole

20

l

:g +

IN +

t1 +

20>C.3

-190

=4

4'2s11 ~

..•

I I

..--.---.

! ! !

-t-+--t

o

Knee lifter installation

position

81

'1101";..,l

,.

Work table processing diagram

A-A cross section

B-B cross section

Oil pan installation position

• Motor

ACAUTION

All cords which are connected to the motor

should be secured at least 25 mm away from

any moving parts. Furthermore, do not ex-

cessively bend the cords or secure them

too

firmly with staples, otherwise there is the

danger that fire or electric shocks could oc-

cur.

A •Install the correct belt guard which corre-•• sponds to the motor being used.

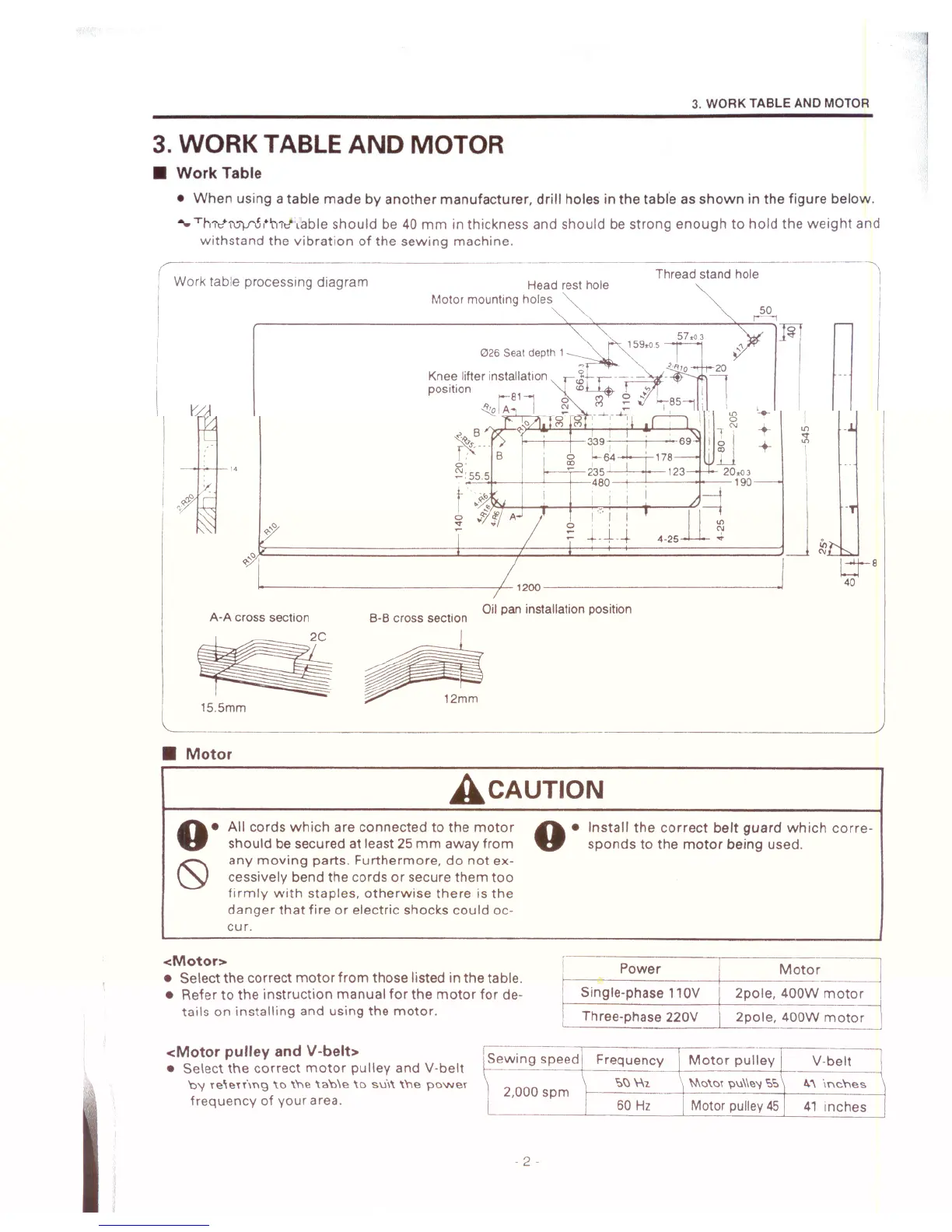

<Motor>

• Select the correct motor from those listed in the table.

• Refer to the instruction manual for the motor for de-

tails on installing and using the motor.

Power

Motor

Single-phase 110V

2pole, 400W motor

Three-phase 220V

2pole, 400W motor

<Motor pulley and V-belt>

• Select the correct motor pulley and V-belt

'o'{ Te'eTf\f\9 \0 \ne \a'o\e \0 su\\ \'he poweT

frequency of your area.

Sewing speed

2,000 spm

Frequency

~\J \-\,

60 Hz

Motor pulley

~Q\Q~ ?u\\~'1SS

Motor pulley 45

V-belt

41 inches

- 2-

Loading...

Loading...