ADJUSTING

THE LIFT

OF

THE ALTERNATING PRESSER FEET

The thickness of

the

material sewn should control the height of

the

lift of

the

alternating presser feet.

It should normally be just high enough for clearance of the material. With

normal adjustment both feet lift to equal height.

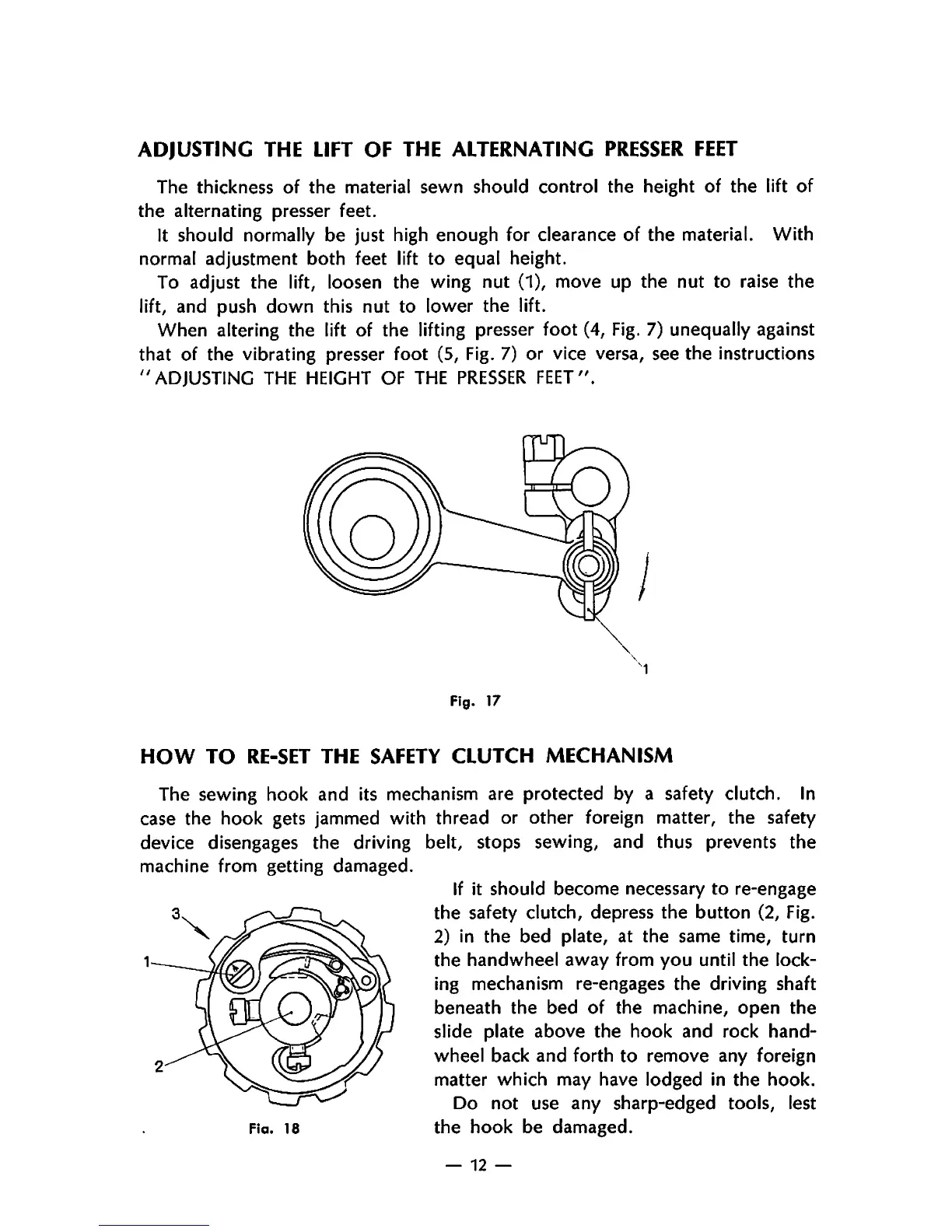

To adjust the lift, loosen the wing nut (1), move up the nut to raise the

lift, and push down this nut to lower the lift.

When altering the lift of the lifting presser foot (4,

Fig.

7) unequally against

that of

the

vibrating presser foot (5, Fig. 7) or vice versa, see

the

instructions

"ADJUSTING

THE HEIGHT OF THE

PRESSER

FEET".

Fig. 17

HOW

TO

RE-SET

THE

SAFETY

CLUTCH

MECHANISM

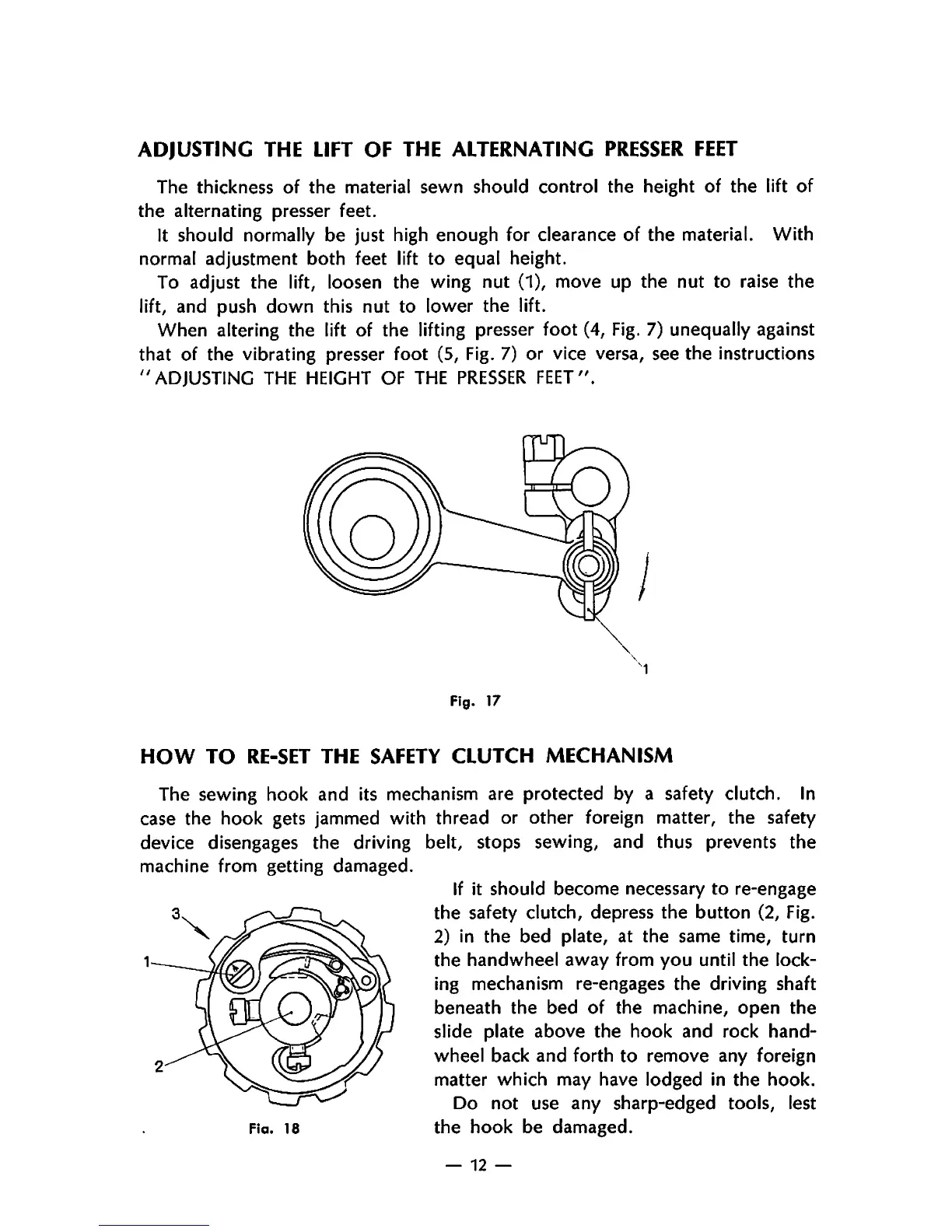

The sewing hook and its mechanism are protected by a safety clutch. In

case the hook gets jammed with thread or other foreign matter, the safety

device disengages

the

driving belt, stops sewing, and thus prevents

the

machine

from getting

damaged.

If it

should

become

necessary to re-engage

the

safety clutch, depress

the

button

(2, Fig.

2) in

the

bed

plate, at

the

same time, turn

the

handwheel

away

from

you

until

the

lock

ing mechanism re-engages

the

driving

shaft

beneath

the

bed

of

the

machine,

open

the

slide plate

above

the

hook

and

rock

hand-

wheel back

and

forth to remove any foreign

matter

which

may have

lodged

in

the

hook.

Do not use any sharp-edged tools, lest

Fia.

18

the

hook

be damaged.

—

12

—

Loading...

Loading...