j'

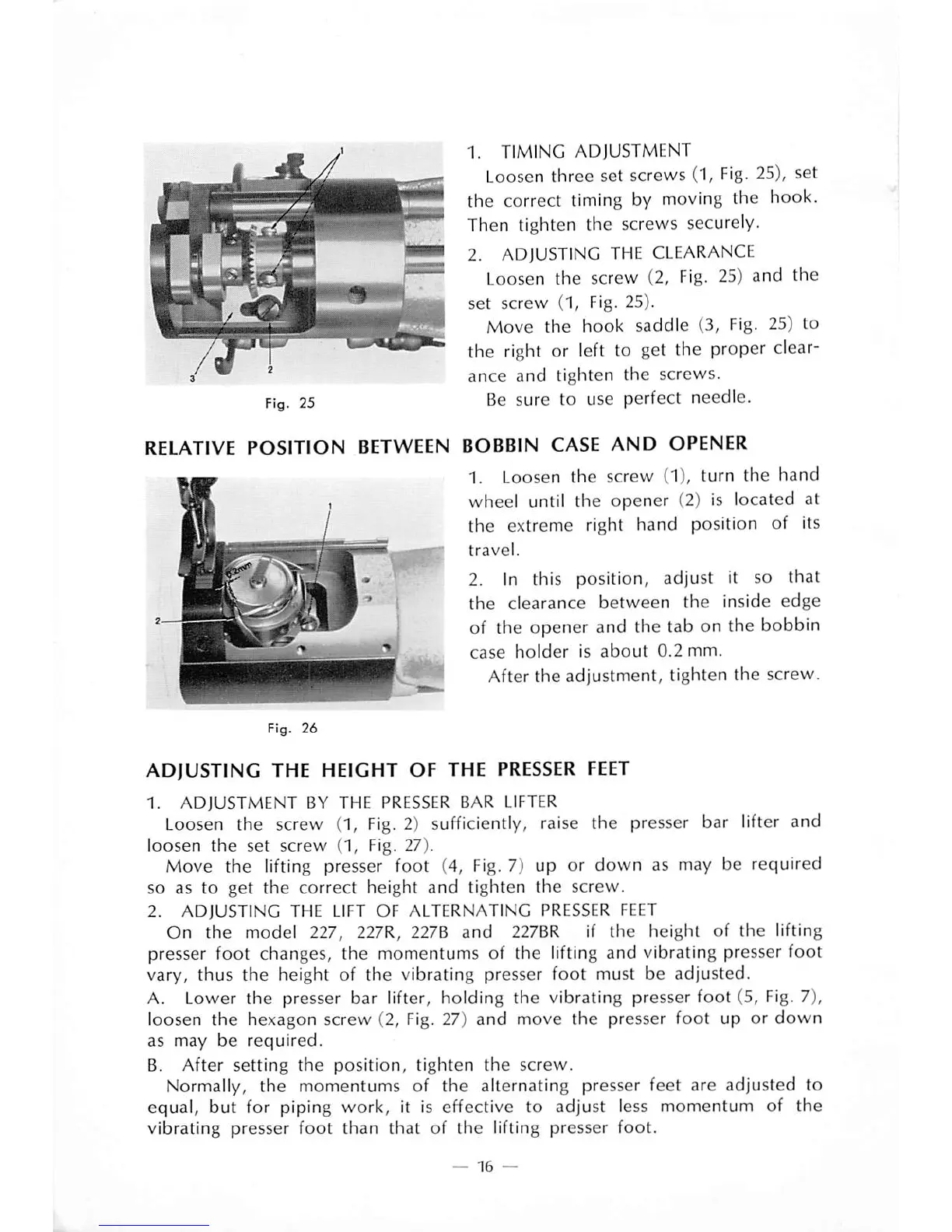

1.

timing

adjustment

/'

ance

and

tighten

the

screws.

Fig.

25

Be

sure

to

use

perfect

needle.

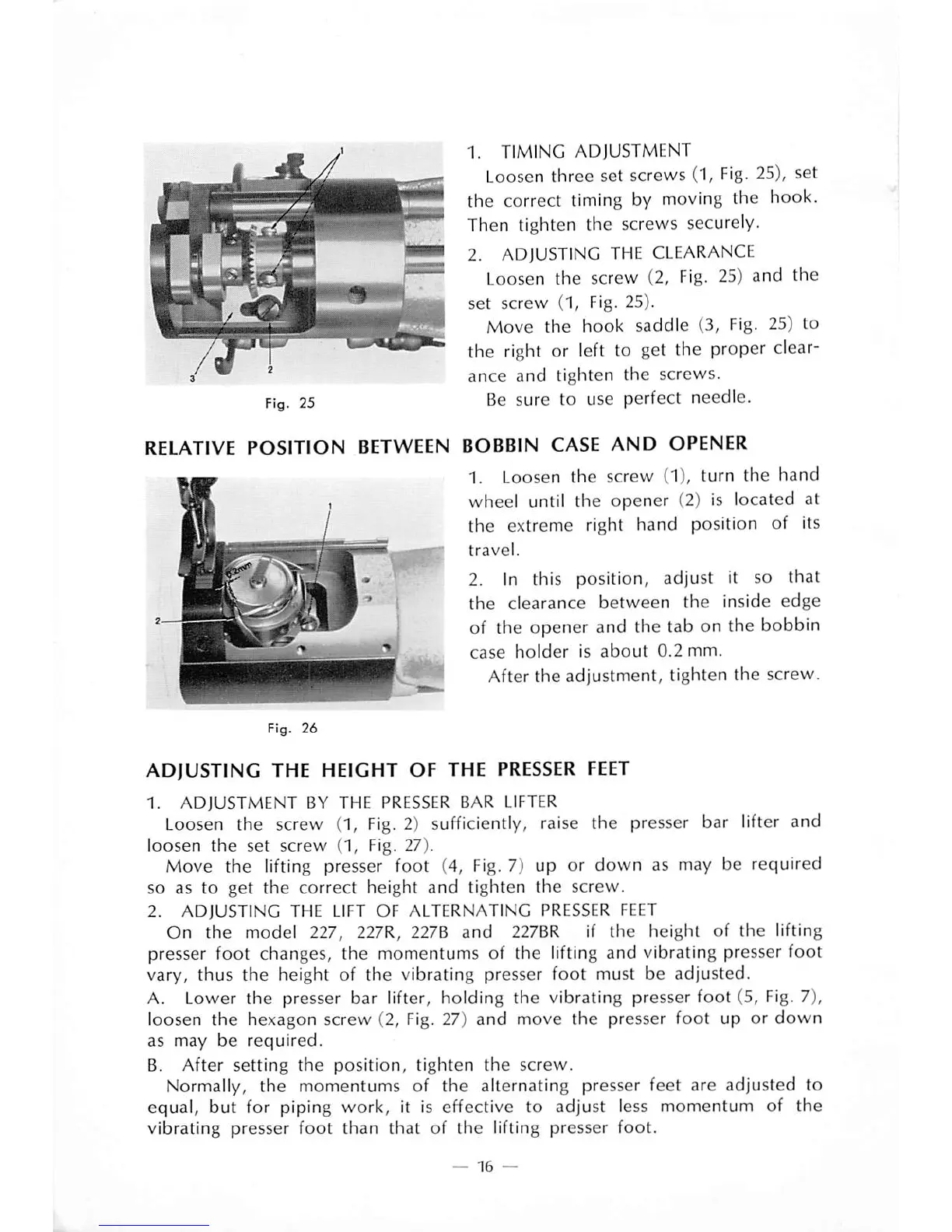

RELATIVE

POSITION

BETWEEN BOBBIN CASE

AND

OPENER

1. Loosen the screw (1), turn the

hand

IR

,

wheel

until

the

opener

(2)

is

located

at

mV

I

the

extreme

right

hand

position

of

its

^ clearance

between

the

inside

edge

^ 1

opener

and

the tab

on

the

bobbin

case

holder

is

about

0.2

mm.

HH[RBRRH|HRII| ^

After

the

adjustment,

tighten

the

screw.

ADJUSTING THE HEIGHT OF THE

PRESSER

FEET

1.

ADJUSTMENT

BY THE PRESSER BAR LIFTER

Loosen

the screw (1,

Fig.

2)

sufficiently,

raise

the presser bar

lifter

and

loosen

the

set

screw

{1, Fig. 27).

Move the

lifting

presser foot (4,

Fig.

7) up or down as may be required

so as to get the correct height and tighten the screw.

2.

ADJUSTING

THE LIFT OF ALTERNATING PRESSER FEET

On

the

model 227, 227R, 2278

and

227BR

if the height of the lifting

presser foot changes, the momentums of the

lifting

and vibrating presser foot

vary, thus the height of the vibrating presser foot must be adjusted.

A. Lower the presser bar lifter, holding the vibrating presser foot (5,

Fig.

7),

loosen the hexagon screw (2,

Fig.

27) and move the presser foot up or down

as may be required.

B. After setting the position, tighten

the

screw.

Normally, the momentums of the alternating presser feet are adjusted to

equal, but for piping work, it is effective to adjust less momentum of the

vibrating presser foot than that of the lifting presser foot.

Loading...

Loading...