TIMING

OF

THE VIBRATING PRESSER

FOOT

This

is the

normal

timing

when, turn the balance wheel toward you, after

lowering the presser bar lifter, the vibrating presser foot should reach the

feeder earlier than the needle eye comes to, and when the needle raises,

the

vibrating

presser foot should

leave

the feeder after the needle eye has

left

the

feeder.

This is due to the reason that the vibrating presser foot must tightly hold

the goods while the needle is

passing

the goods for

avoiding

irregular

stitches.

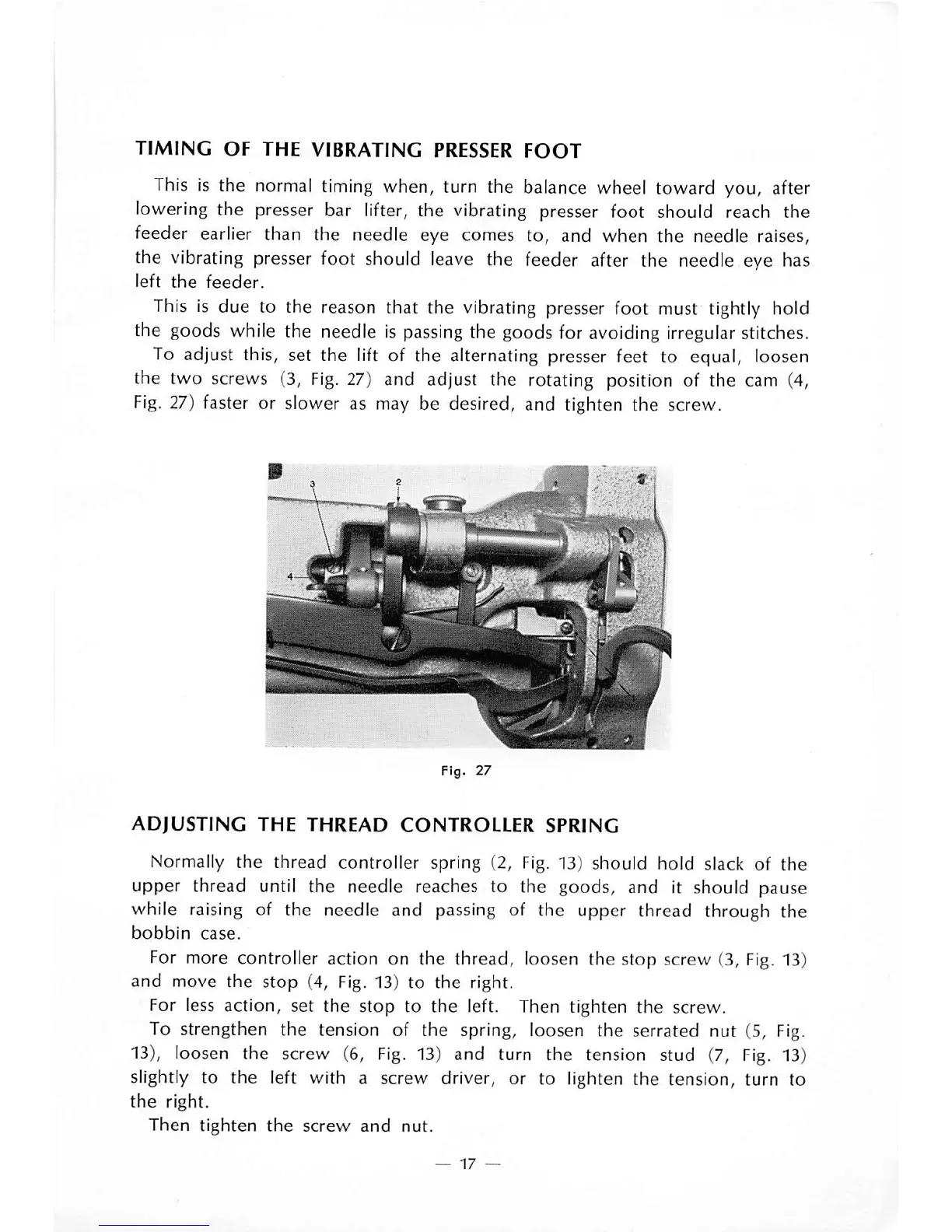

To adjust this, set the lift of the alternating presser feet to equal, loosen

the two screws (3,

Fig.

27)

and adjust the rotating position of the cam (4,

Fig.

27) faster or slower as may be desired, and tighten the screw.

ADJUSTING

THE

THREAD

CONTROLLER

SPRING

Normally the thread controller spring (2,

Fig.

13) should hold slack of the

upper thread until the needle reaches to the goods, and it should pause

while raising of the needle and passing of the upper thread through the

bobbin

case.

For more controller action on the thread, loosen the stop screw (3,

Fig.

13)

and

move the stop (4,

Fig,

13) to the right.

For less action, set the stop to the left. Then tighten the screw.

To strengthen the tension of the spring, loosen the serrated nut (5,

Fig.

13), loosen the screw (6,

Fig.

13) and turn the tension stud (7,

Fig.

13)

slightly to the left with a screw driver, or to lighten the tension, turn to

the

right.

Then tighten

the

screw

and

nut.

Loading...

Loading...