ADJUSTING THE HEIGHT OF THE FEED

DOG

1 The

maximum

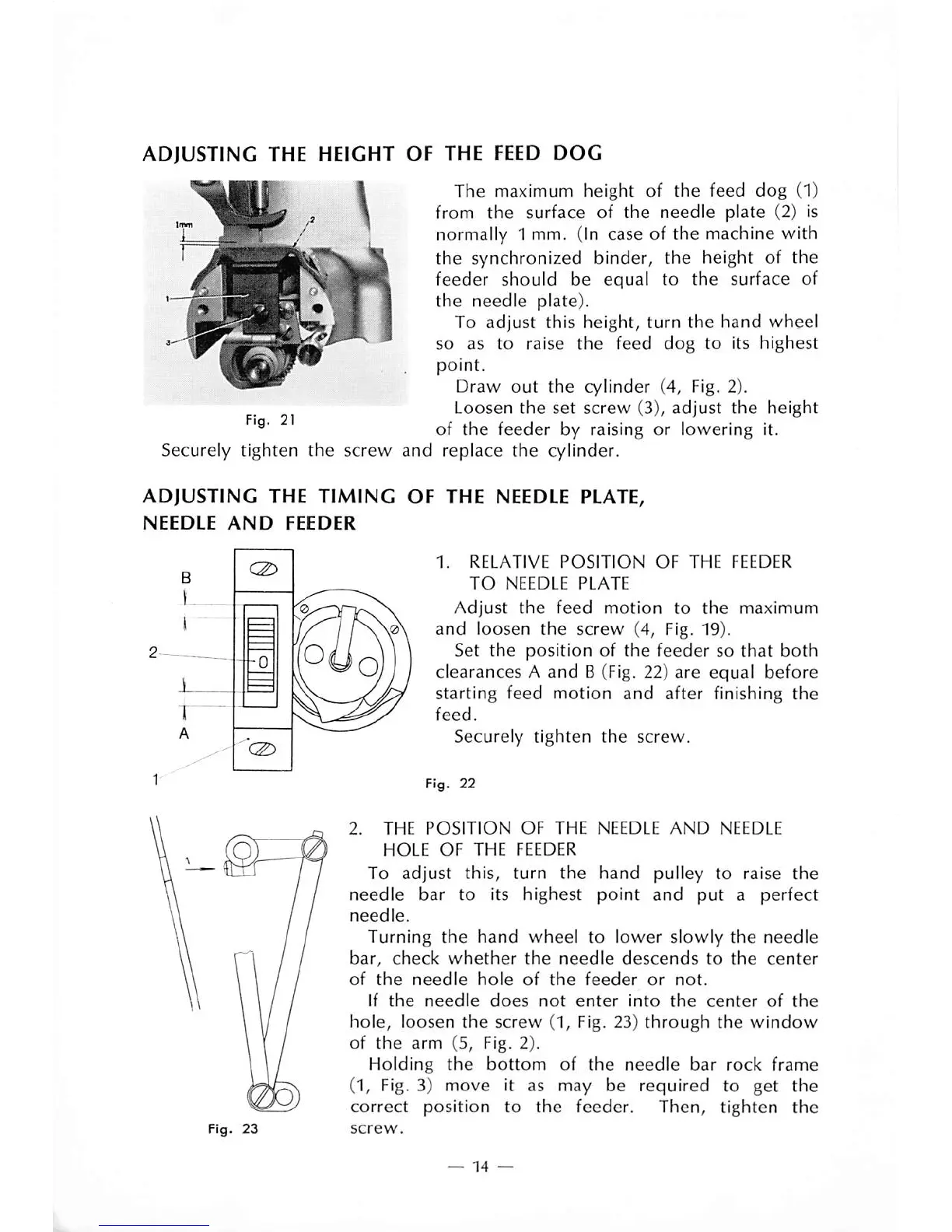

height of the feed dog (1)

j 1 from the surface of the needle plate (2) is

T / *

normally

1

mm.

(In

case

of

the

machine

with

I m the

synchronized

binder,

the

height

of the

feeder should be equal to the surface of

I

adjust

this

height,

turn

the

hand

wheel

so as to raise

the

feed dog to its highest

Draw

out

the

cylinder (4, Fig. 2).

p.

Loosen

the

set

screw

(3),

adjust

the

height

of

the

feeder by raising or lowering it.

Securely tighten the

screw

and replace

the

cylinder.

ADJUSTING

THE

TIMING

OF

THE NEEDLE PLATE,

NEEDLE

AND

FEEDER

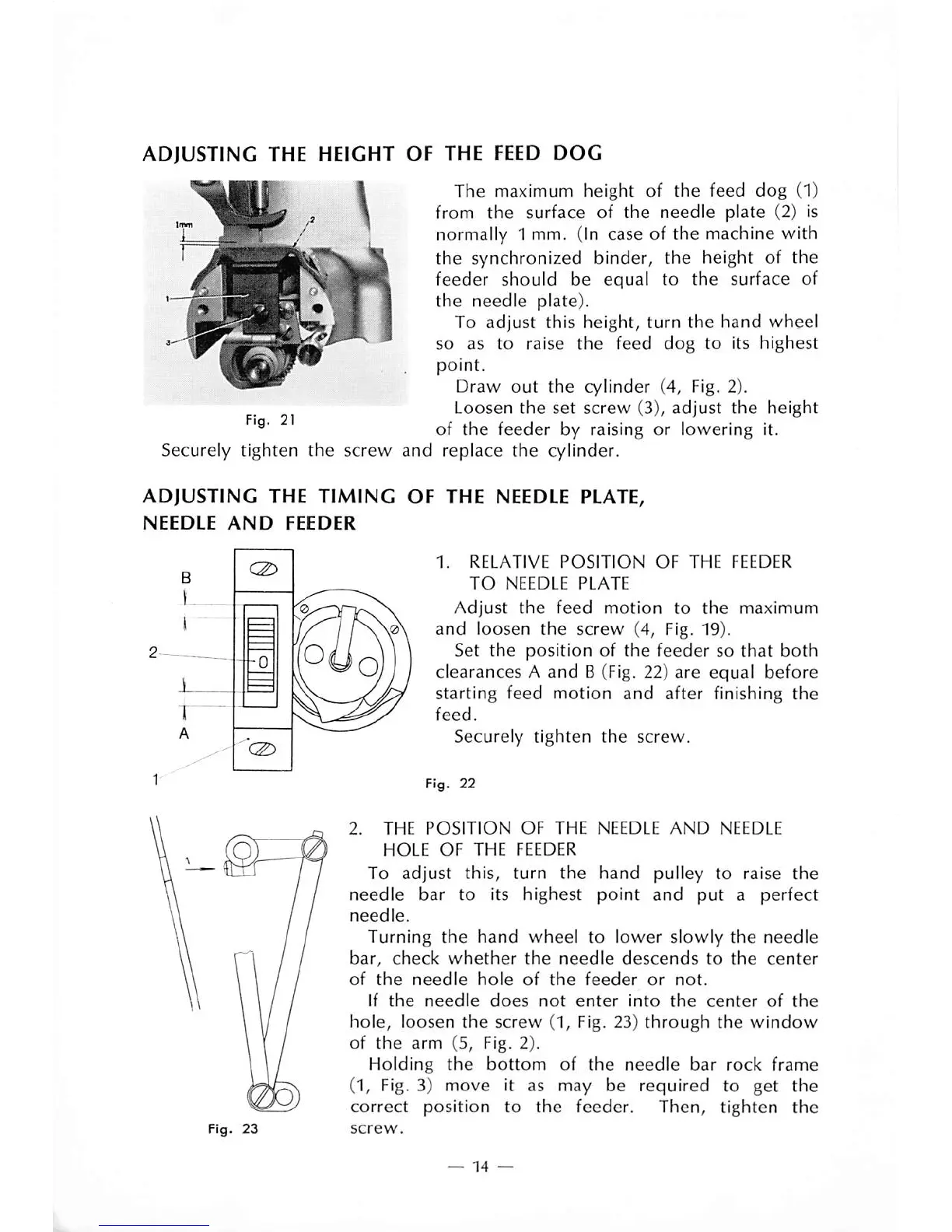

Fig. 23

1.

RELATIVE

POSITION

OF

THE

FEEDER

TO

NEEDLE

PLATE

Adjust

the

feed

motion

to

the

maximum

and

loosen

the

screw

(4, Fig. 19).

Set

the

position of

the

feeder

so

that

both

clearances A

and

B(Fig. 22)

are

equal

before

starting feed motion and after finishing the

feed.

Securely

tighten

the

screw.

Fig. 22

2.

THE

POSITION

OF

THE

NEEDLE

AND

NEEDLE

HOLE

OF

THE

FEEDER

To adjust this, turn

the

hand

pulley to raise

the

needle bar to its highest point and put a perfect

needle.

Turning

the

hand

wheel

to

lower

slowly

the

needle

bar,

check

whether

the

needle

descends

to

the

center

of

the

needle

hole

of

the

feeder

or

not.

If

the

needle

does

not

enter

into

the

center

of

the

hole,

loosen

the

screw

(1, Fig. 23)

through

the

window

of

the

arm (5, Fig. 2).

Holding

the

bottom

of

the

needle

bar rock frame

(1,

Fig.

3) move it as may be required to get the

correct

position

to

the

feeder.

Then,

tighten

the

—

14

—

Loading...

Loading...