SPEED

Maximum operating

speed

after a break-in period is 3000 stitches per minute

depending, of course, on the type of material being sewn, its thickness and

that of seams being crossed. (In case of the machine with reverse lever or

synchronized

binder

2800

r.p.m.)

To assure durability

and

trouble-free

operation,

it is

recommended

that

for

the

first several weeks of operation the maximum speed is held to not more

than 2400 RPM in order to allow the parts to become properly broken in.

in

operation

the

hand

wheel

of

the

machine always turn

toward

the

operator.

OILING

Do not

operate

the machine, even if only for testing, unless it has been

properly oiled at every

spot

requiring lubrication.

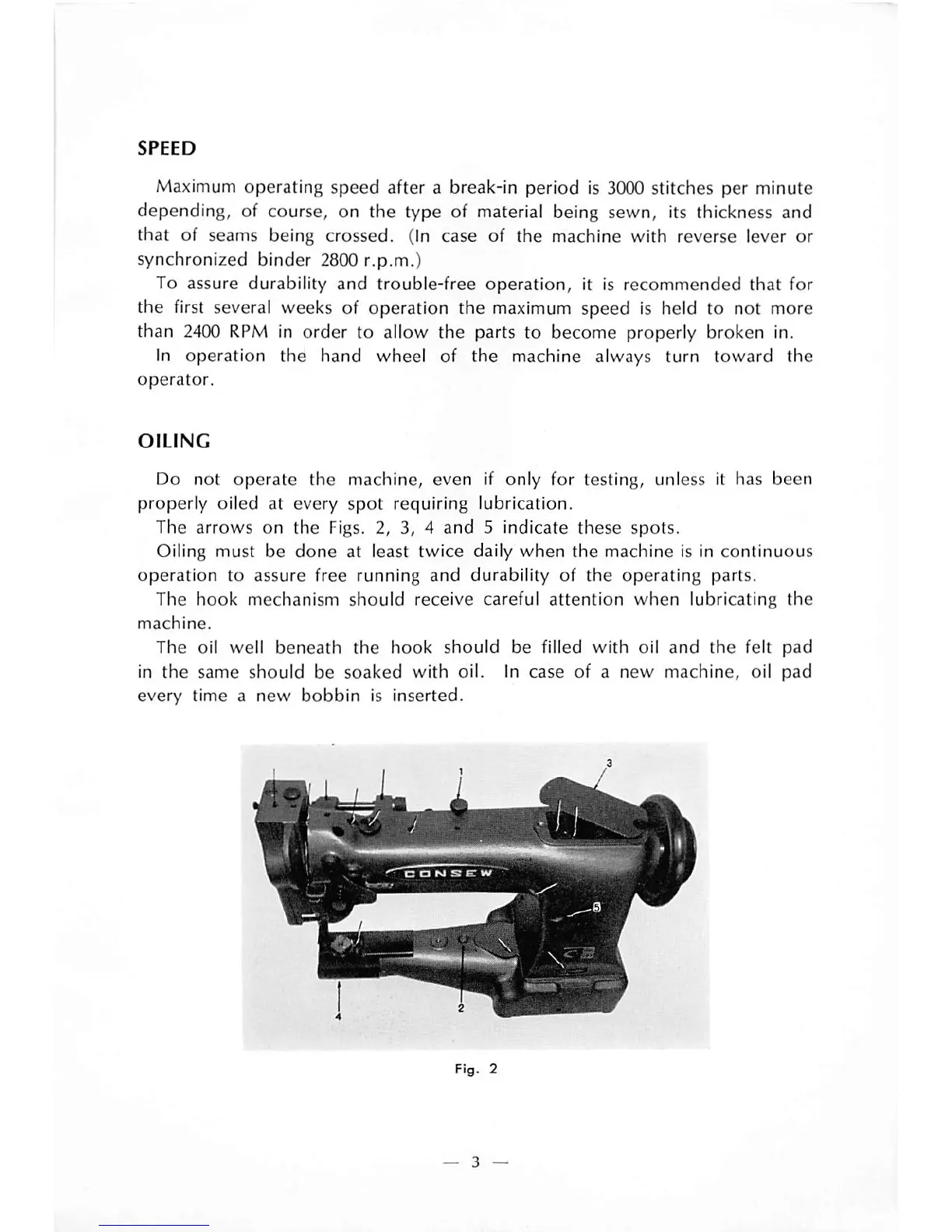

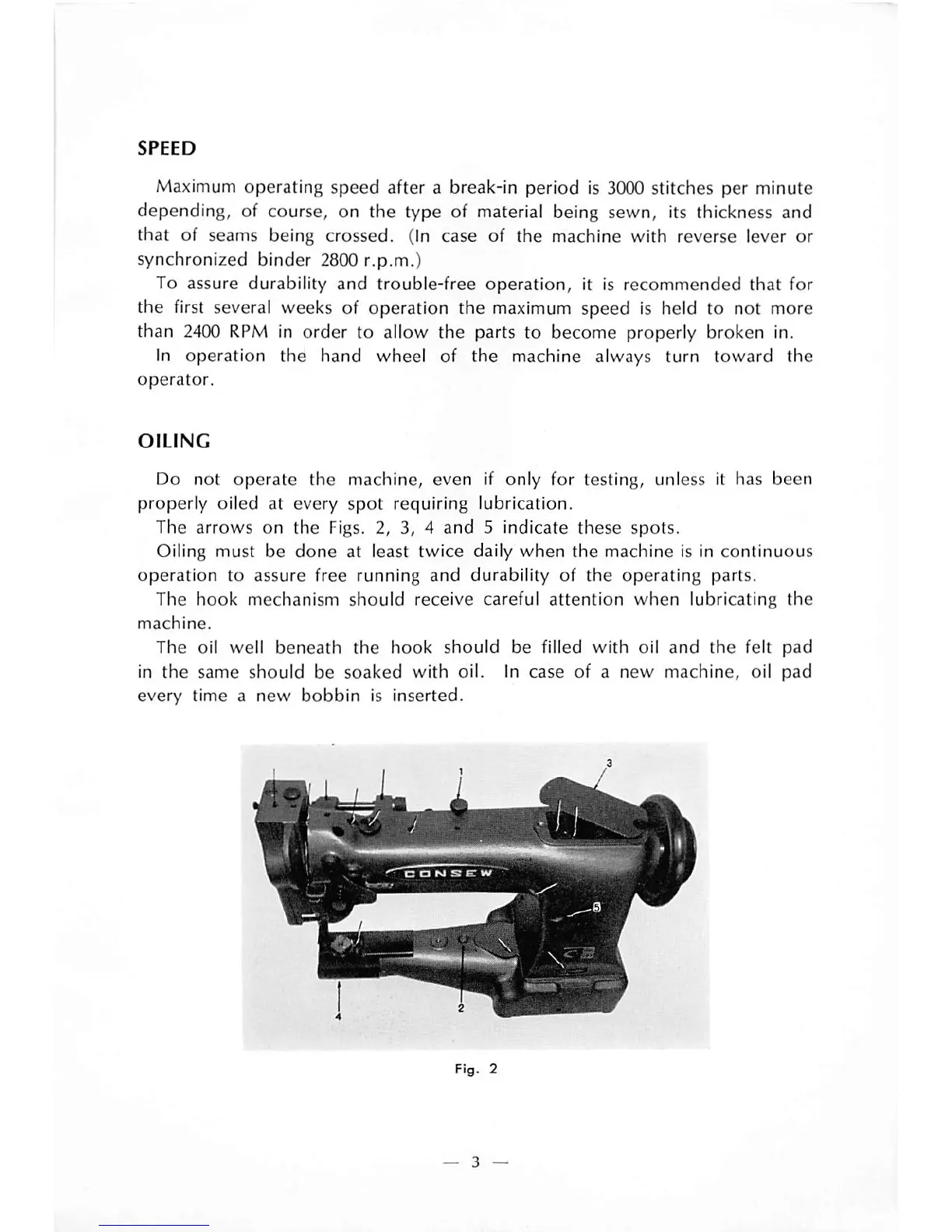

The

arrows

on the Figs. 2, 3, 4

and

5 indicate

these

spots.

Oiling must be

done

at least

twice

daily

when

the

machine is in

continuous

operation

to assure free running

and

durability of

the

operating

parts.

The

hook

mechanism should receive careful

attention

when

lubricating

the

machine.

The oil well

beneath

the

hook

should

be filled with oil

and

the

felt

pad

in

the

same

should

be

soaked

with oil. in case of a

new

machine, oil

pad

every

time a

new

bobbin

is inserted.

Loading...

Loading...