ADJUSTING

THE HEIGHT

OF

THE NEEDLE BAR

1.

When

the

needle

bar

Is

at

its

highest

point,

normally

the

measurement

between

the

surface

of the

needle

plate

and

the

upper

end

of the

needle

eye is

21.1

mm

(in case of the

machine

with the synchronized binder, it is

19.3

mm).

To

adjust

this,

loosen

the

screw

(2,

Fig.

3),

move

the

setting

position

of

the

needle

bar

and

needle

bar

connecting

stud

(3,

Fig.

3)

to get the

correct

position. Then tighten

the

screw.

2.

There

is

another

method

for this

adjustment

by

setting

the

needle

bar

to its lowest point.

The

normal

position,

in

this

case,

is 4

mm

approximately

from

the

hook

point to the upper end of the needle eye.

NOTE:

These

measurements

are

approximate

standard,

accordingly,

following

final

adjustments

are

recommended.

TIMING

BETWEEN THE

HOOK

AND

NEEDLE

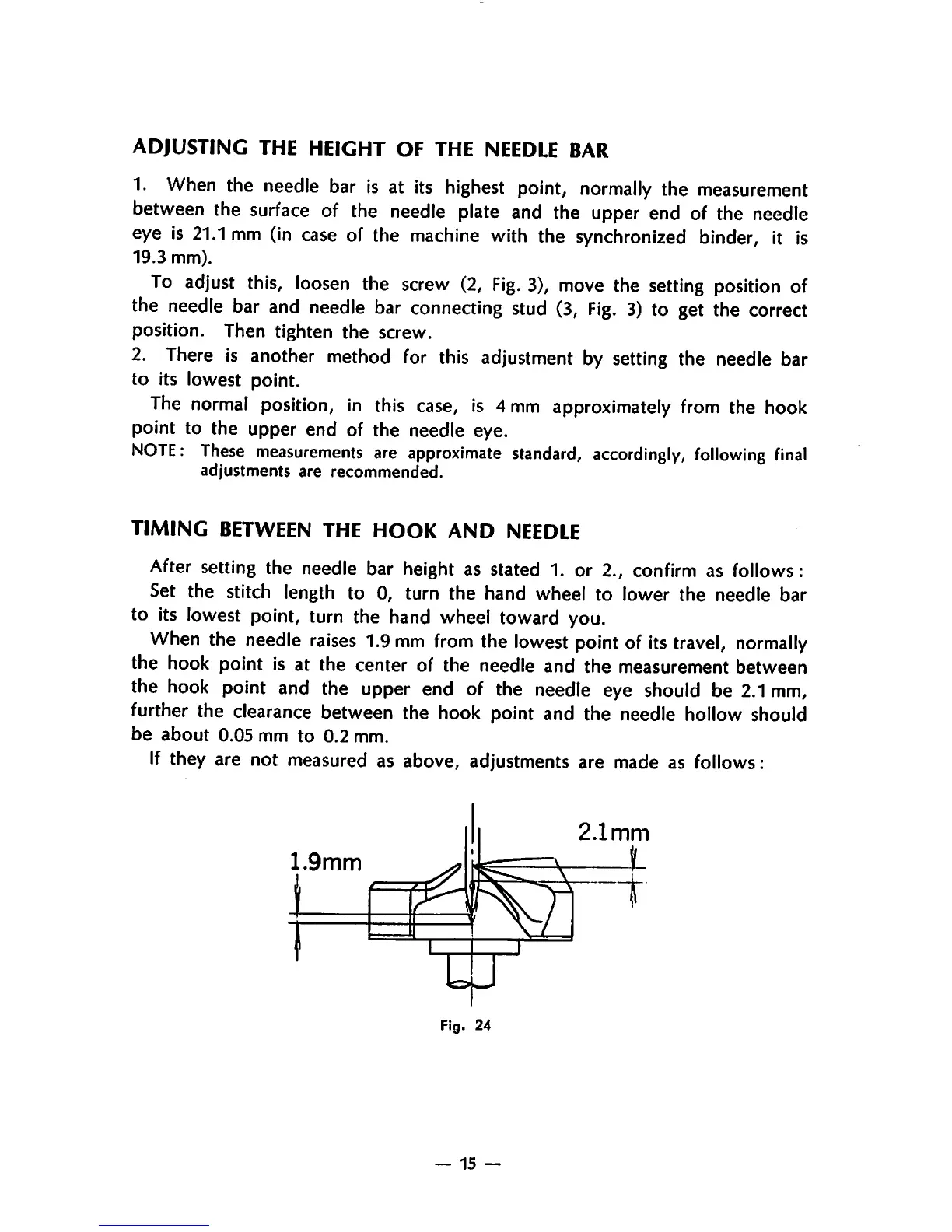

After setting the needle bar height as stated 1. or 2., confirm as follows:

Set the stitch length to 0, turn the hand wheel to lower the needle bar

to its

lowest

point, turn the hand wheel toward you.

When

the

needle

raises

1.9

mm

from

the

lowest

point

of

its

travel,

normally

the hook point is at the center of the needle and the measurement between

the hook point and the upper end of the

needle

eye

should

be

2.1

mm,

further the clearance between the hook point and the needle hollow should

be

about

0.05

mm

to

0.2

mm.

If they are not measured as above, adjustments are made as follows:

2.1mm

1.9mm

Fig. 24

—

15

—

Loading...

Loading...