Safety

Information

Product

Information

Mechanical

Installation

Electrical

Installation

Getting

Started

Menu 0

Running

the motor

Optimisation Macros

Advanced

Parameters

Technical

Data

Diagnostics

UL Listing

Information

Unidrive User Guide 43

Issue Number: 9 www.controltechniques.com

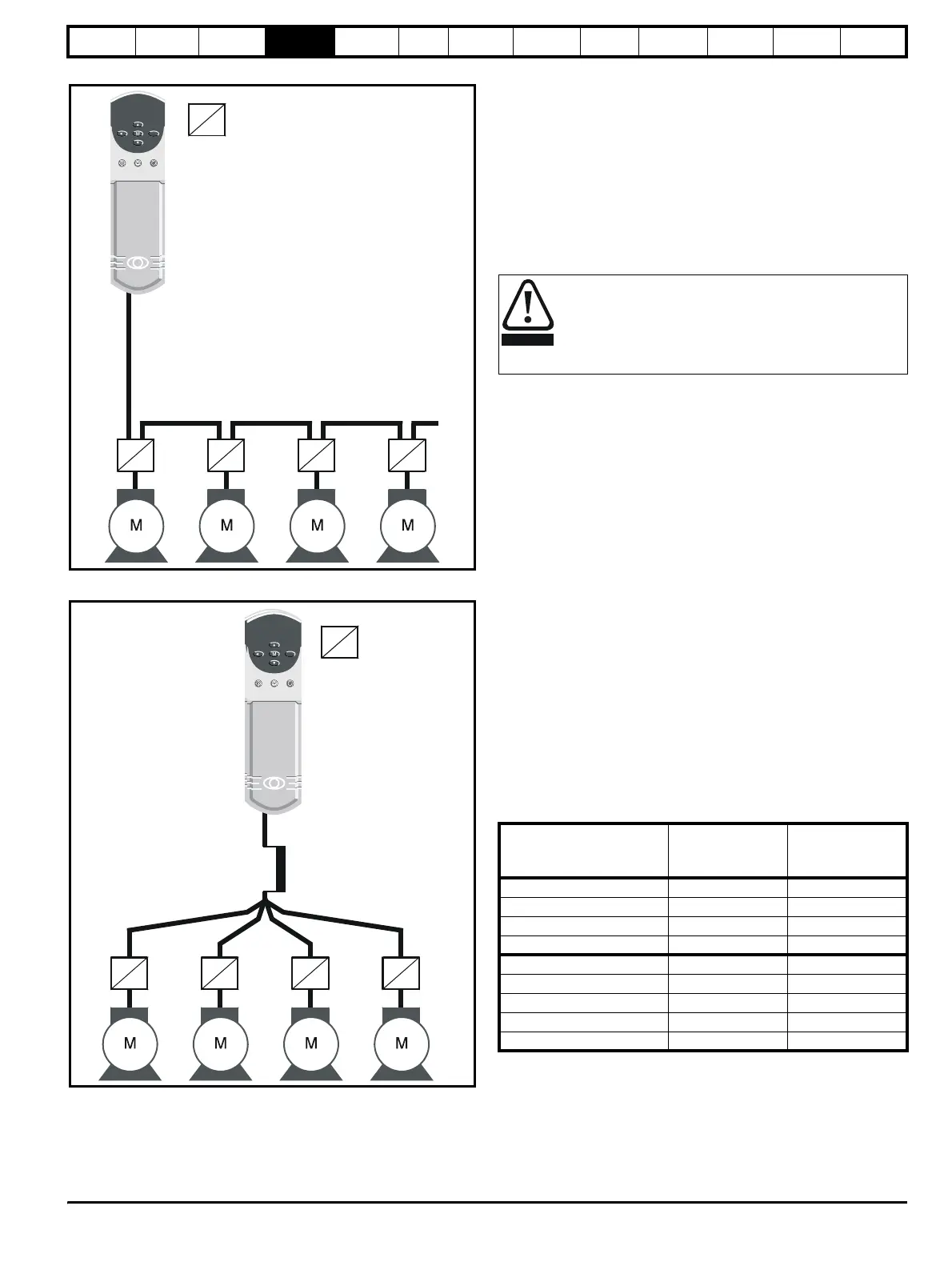

Figure 4-5 Preferred chain connection for multiple motors

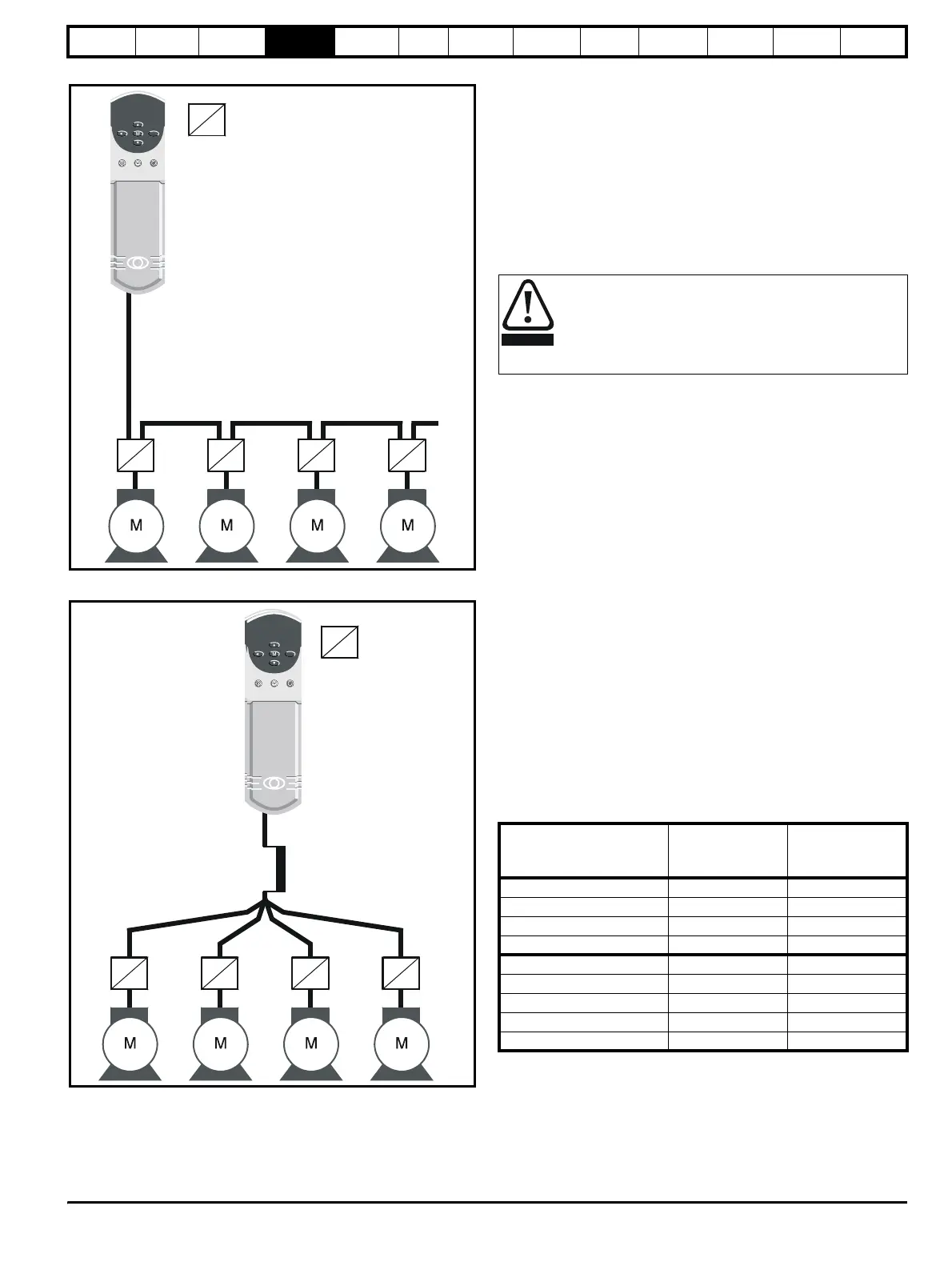

Figure 4-6 Alternative connection for multiple motors

4.5.3 Star / delta motor operation

The voltage rating for star and delta connections of the motor should

always be checked before attempting to run the motor.

The default setting of the motor rated voltage parameter is the same as

the drive rated voltage

i.e. 400V drive 400V rated voltage

200V drive 200V rated voltage

A typical 3 phase motor would be connected in star for 400V operation

or delta for 200V operation however variations on this are common

i.e. star 690V delta 400V

Incorrect connection of the windings will lead to severe under or over

fluxing of the motor, leading to a very poor output torque or motor

saturation and over-heating respectively.

4.5.4 Output contactor

A contactor is sometimes required to be fitted between the drive and

motor for safety isolation purposes.

The recommended motor contactor is the AC3 type.

Switching of an output contactor should only occur when the output of

the drive is disabled.

Opening or closing of the contactor with the drive enabled will lead to:

1. OI.AC trips (which cannot be reset for 10 seconds)

2. High levels of RFI noise emission

3. Increased contactor wear and tear

For more information please contact the supplier of the drive.

4.6 Braking

Internal connection does not require the cable to be armoured or

shielded.

In-built in the Unidrive software is overload protection for the brake

resistor. In order to enable and set-up this function, it is necessary to

enter two values into the drive:

• Resistor short-time overload time (Pr 10.30)

• Resistor minimum time between repeated short-time overloads (Pr

10.31)

This data is available from the manufacturer of the braking resistors.

4.6.1 Minimum resistances and power ratings

Table 4-4 Minimum resistance values and peak power rating for

the braking resistor at 40°C (104°F)

The minimum resistance allows the braking resistor to dissipate up to

approximately 150% of the power rating of the drive for up to 60

seconds.

For high-inertia loads or under continuous braking, the continuous power

dissipated in the braking resistor may be as high as the power rating of

the drive. The total energy dissipated in the braking resistor is dependent

on the amount of energy to be extracted from the load.

Motor protection

relay

Chain connection (preferred)

Star connection

Inductor

Motor protection

relay

If the cable between the drive and the motor is to be

interrupted by a contactor or circuit breaker, ensure that the

drive is disabled before the contactor or circuit breaker is

opened or closed. Severe arcing may occur if this circuit is

interrupted with the motor running at high current and low

speed.

Model

Minimum

resistance

Ω

Instantaneous

power rating

kW

UNI1201 to UNI1205 20 15

UNI2201 20 15

UNI2202 to UNI2203 15 20

UNI3201 to UNI3205 5 60

UNI1401 to UNI1405 40 15

UNI2401 40 15

UNI2402 to UNI2403 30 20

UNI3401 to UNI3405 10 60

UNI4401 to UNI4405 5 120

WARNING

Loading...

Loading...