ORDINARY MAINTENANCE - 37

COROB™ D600 - D700 - D800 EXTRA

7 ORDINARY MAINTENANCE

7.1 General warnings

DANGER

Before carrying out any maintenance operations, you must turn off the machine and unplug the power supply

cable from the mains socket outlet.

During machine maintenance operations there is a high risk of contact with the coloring product; strictly

follow the indications of chapter 2.2.

7.2 Maintenance table

WARNING

The frequencies indicated are approximate, since they depend on the type of colorants, environment conditions

and frequency of use of the machine.

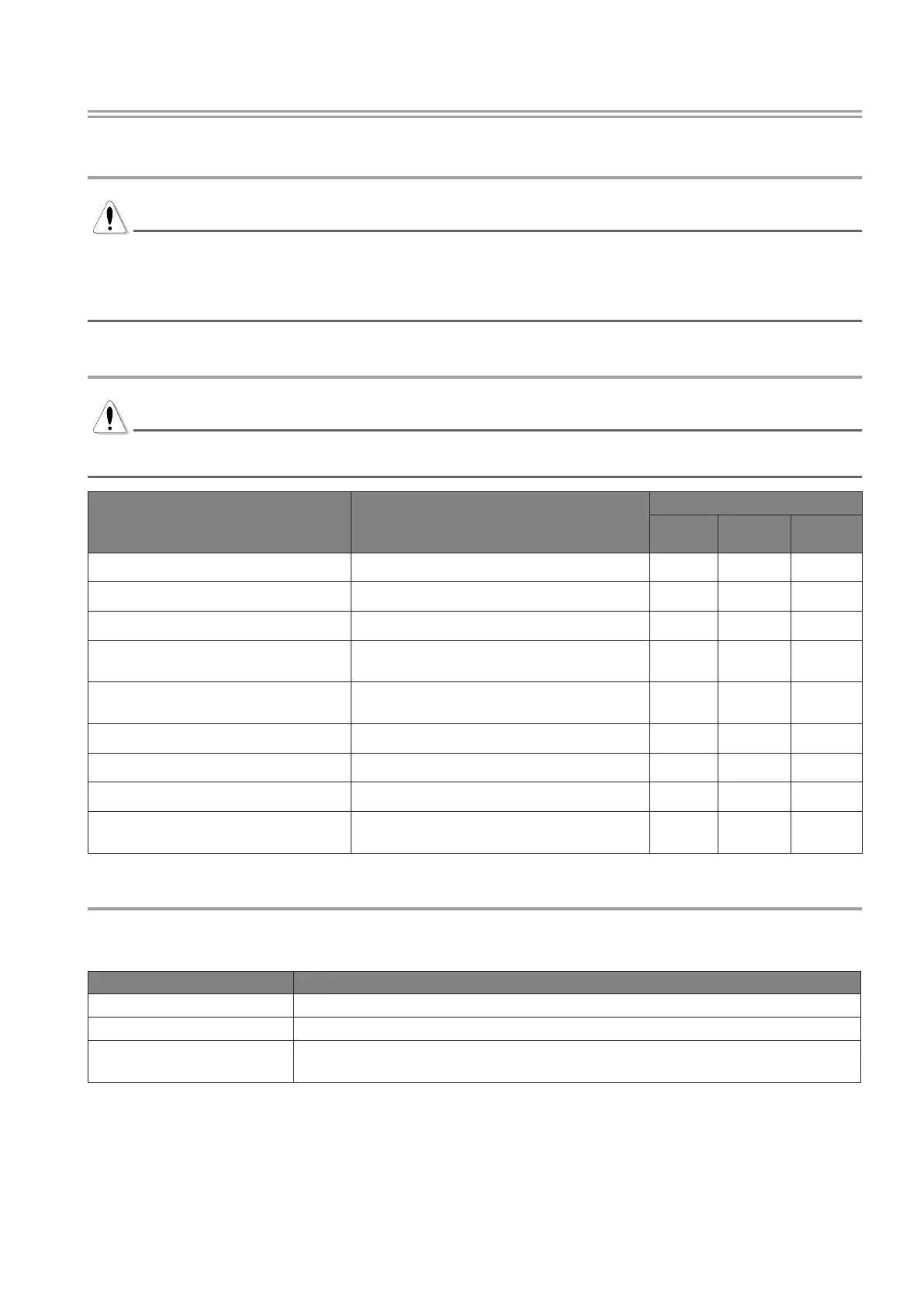

Operations Accessories

Frequency

beginning

of shift

twice a

week

when

necessary

Initialize and purge machine

Clean the nozzle center

Check the sponge is clean

Check the sponge is saturated

with humidier system for solvent-based

colorants or without humidier system

Moisten the sponge

with humidier system for solvent-based

colorants or without humidier system

Clean the sponge

Check condition of puncher with punching device

Clean the dispenser externally

Fill up the humidier system bottle

with humidier system for water-based

colorants

7.3 Products to be used

We recommend to use products compatible with the type of colorants in the machine when cleaning the nozzle

center and moistening the humidier cap sponge.

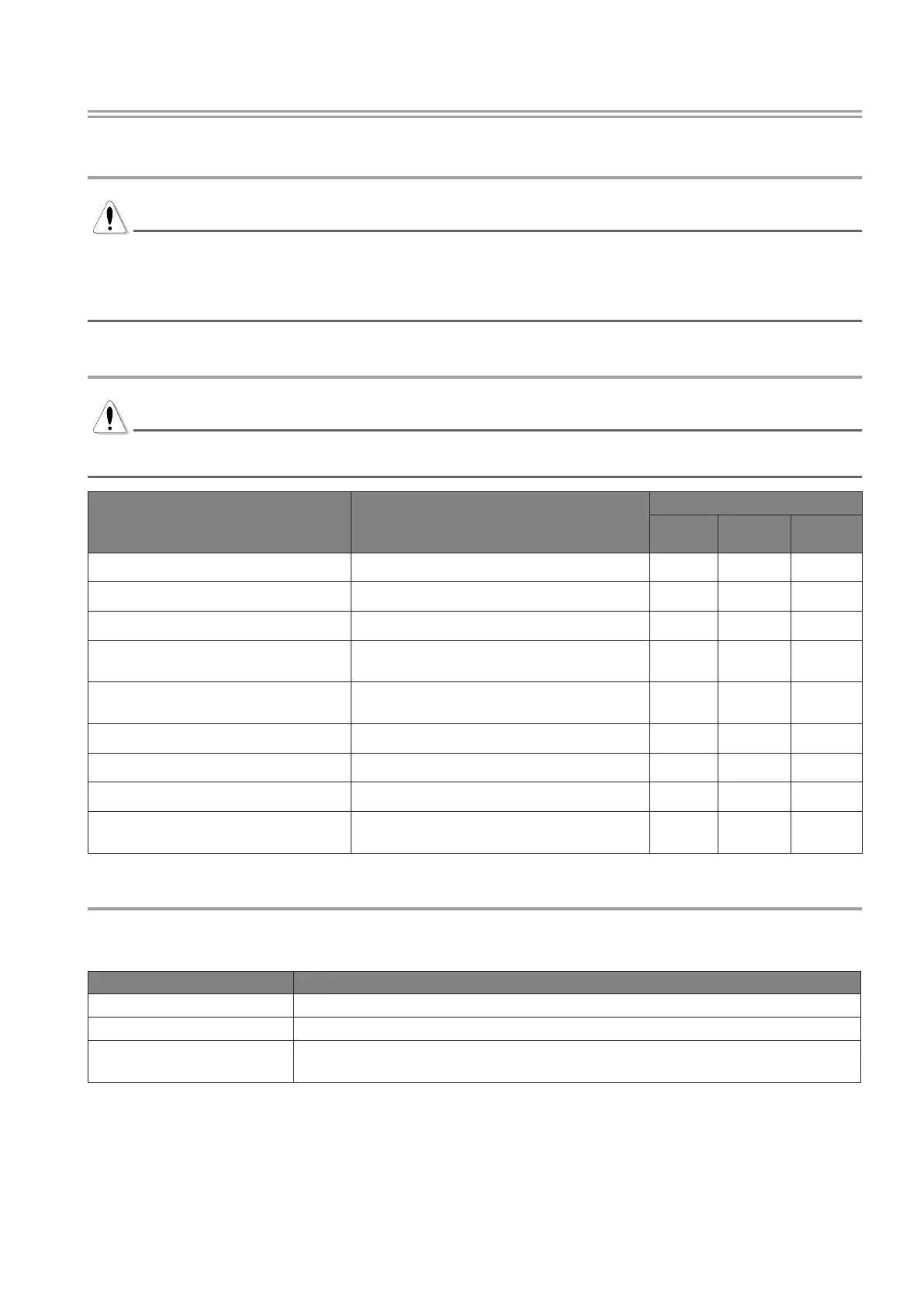

Type of colorant Suggested product

Solvent-based colorants slow-evaporating solvent, compatible with the colorants used

Water-based colorants water

Mixed systems

the choice depends on the type of vehicles used to produce the colorants; for

more information, contact the dealer or colorant manufacturer.

Should growths form in the Autocap, in the sponges or in the humidier system water bottle, it is advisable to

use the following uids:

• Propylene glycol solution, 50% by volume, in water;

• AgCl solution in water;

• Bleach (dilution 1%).

Loading...

Loading...