28 - USING THE DISPENSER

COROB™ FIRST 70

8. Update the colorant level value for the topped up canisters in the machine management software (refer to

the software user’s manual).

WARNING

In case of improper actions, which caused canister overlling with colorant:

• In case the colorant has poured inside the machine, do not try to clean; turn the machine off at once and

contact an authorized service center.

• If, on the contrary, the product has already poured out of the canister, it is necessary to shut off the

machine immediately and clean with paper or a moistened cloth. Whenever possible, leave the colorant to

dry itself and remove with a spatula.

• If the product has not yet come out of the canister borders, it is necessary to avoid closing the canister

with its lid and provide immediately to dispense the exceeding colorant until the correct level is reached.

Clean carefully the upper border of the canister with paper or a moistened cloth before closing it with the

lid.

NEVER USE WATER OR SOLVENT-BASED CLEANING PRODUCTS TO CLEAN THE MACHINE.

DANGER

When using colorants containing volatile solvents the canister top up must be carried out opening one

canister at the time.

WARNING

Failure to update the colorant levels in the canisters may compromise the accuracy of the hue produced or,

worse yet, lead to emptying the machine canisters and circuits.

If “SOLVENT FREE” colorants are used, or those that dry out quickly, we recommend that you keep the

canisters full at all times by topping up frequently.

After topping up the colorant, it is advisable to carry out the stirring process using the functions provided in the

management software, to eliminate any air that may be emulsied and incorporated into the colorant.

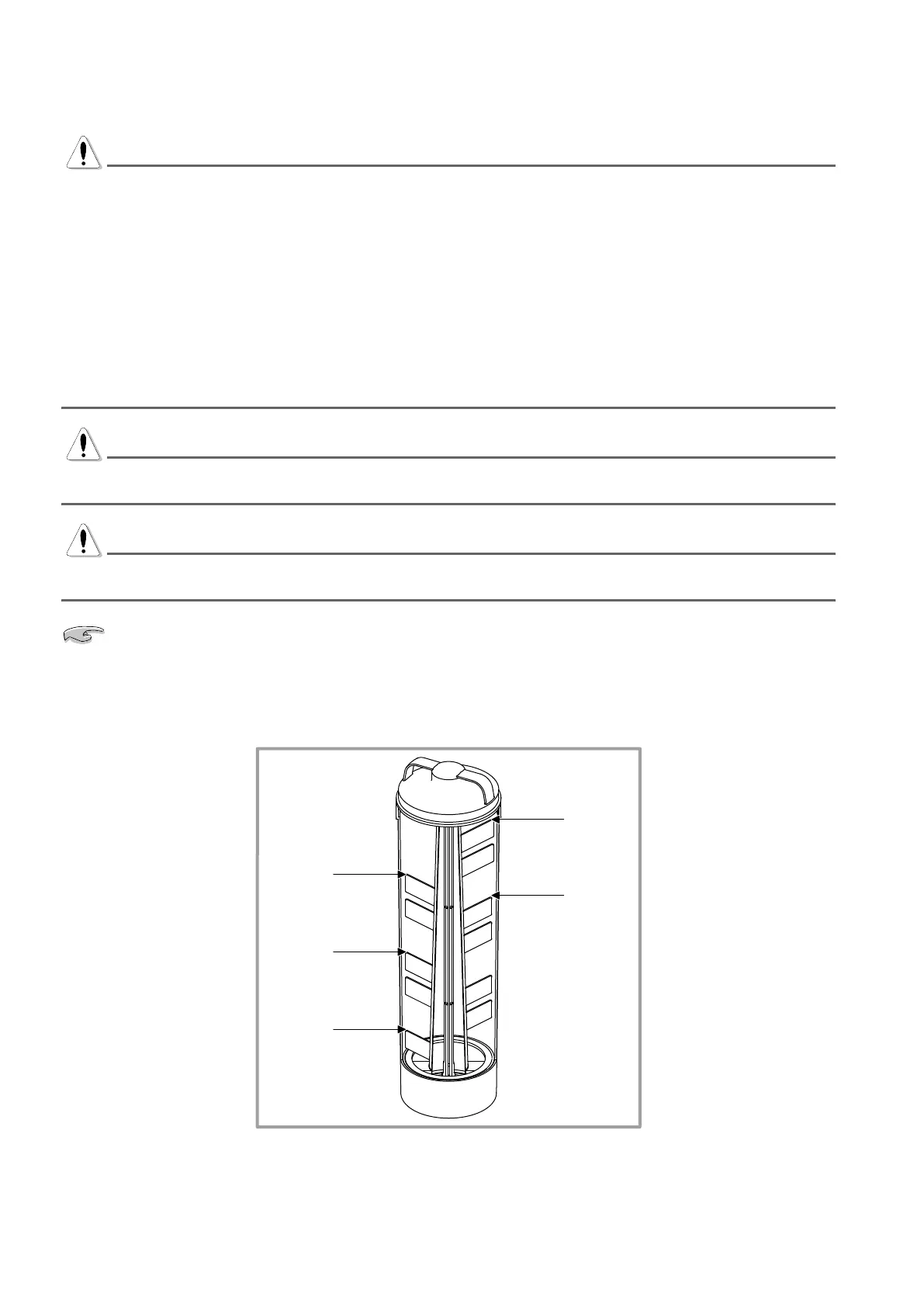

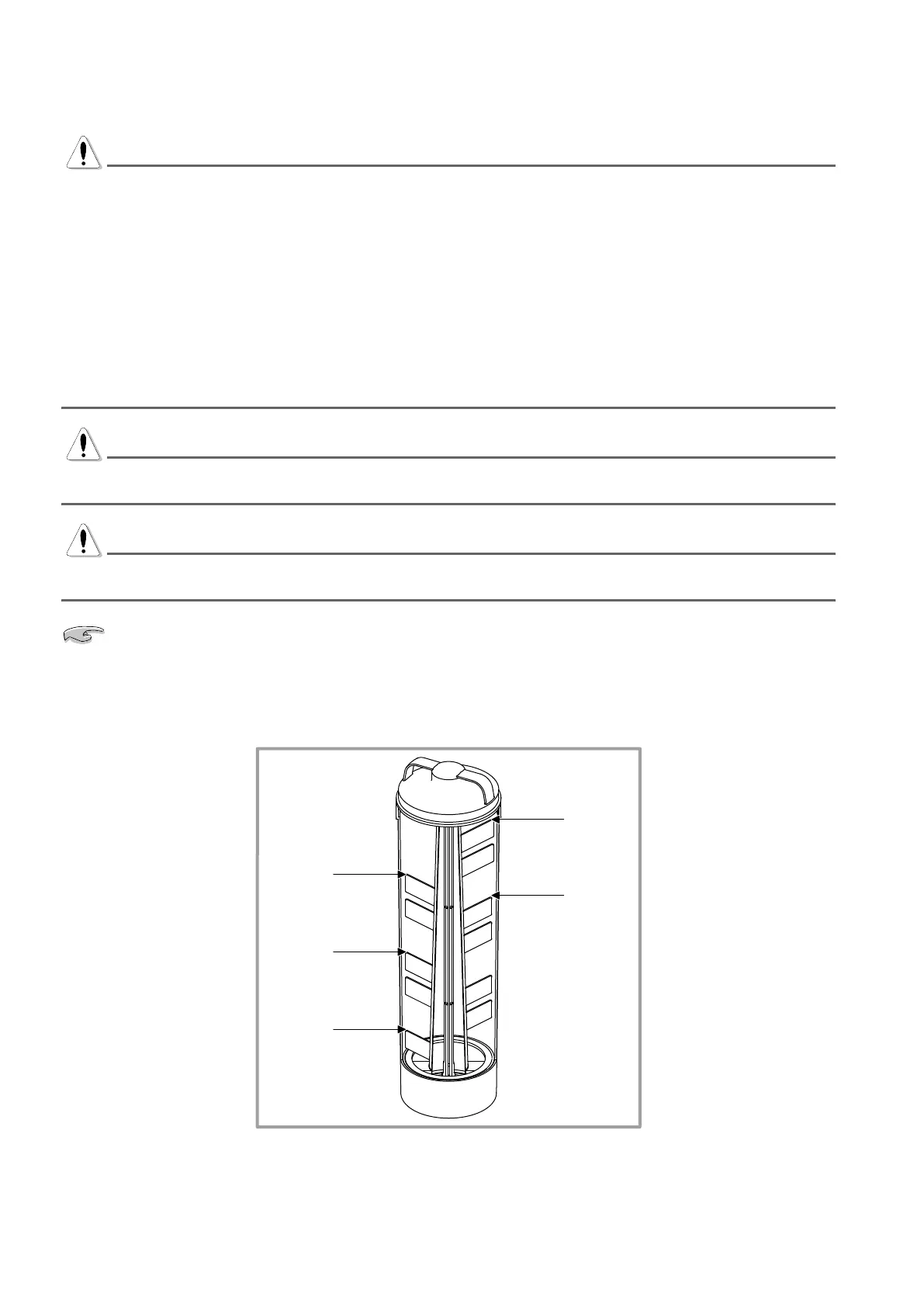

Here below you will nd a reference diagram to perform canister lling.

MAX

2.5 l

2.6 qt

1.8 l

1.9 qt

2 l

2.1 qt

1.2 l

1.3 qt

0.5 l

0.5 qt

Figure 13

Loading...

Loading...