26

L510023-07

ENGINE COMPARTMENT VENTILATION

USCG & ABYC Standards

United States Coast Guard regulations (33 CFR Section

183, subpart J & K) must be adhered to in any fuel and

ventilation system installation. In addition, we strongly

suggest that ABYC’s recommendations regarding fuel

systems and engine room ventilation be followed.

Care must be exercised in the design and construction

of the engine compartment. Hatch openings must be

located so that any rain water, which may leak through

the seams, is directed away from the engine. If water

enters the fl ame arrestor, it can enter the engine and

cause serious damage to internal engine parts.

IMPORTANT: Crusader Engines will not honor any

warranty claim for engine damage as a result of

water entry.

Over the past several years, engine compartments have

been made smaller and insulated to be quieter. This

trend, while resulting in quieter boats, has resulted in

higher engine compartment temperatures. It is important

that attention be given to the air temperatures inside

the engine compartment while running and for a period

of time after the engine is shut off. This period of time

after shutting off the engines is critical as temperatures

normally rise (heat soak) and can lead to fuel vapor lock

causing the engine startability problems.

Engine compartment must be designed to provide a

suffi cient volume of air for engine breathing, and must

vent off any fumes in engine compartment. It should

also be designed to allow heated air to escape and

maintain low temperatures during engine operation.

Cool air should enter the engine compartment as low as

possible and heated air should be vented from as high a

point as possible.

IMPORTANT: The size of ventilation opening must

be increased if any auxiliary equipment, such as

generators, is located in the engine compartment.

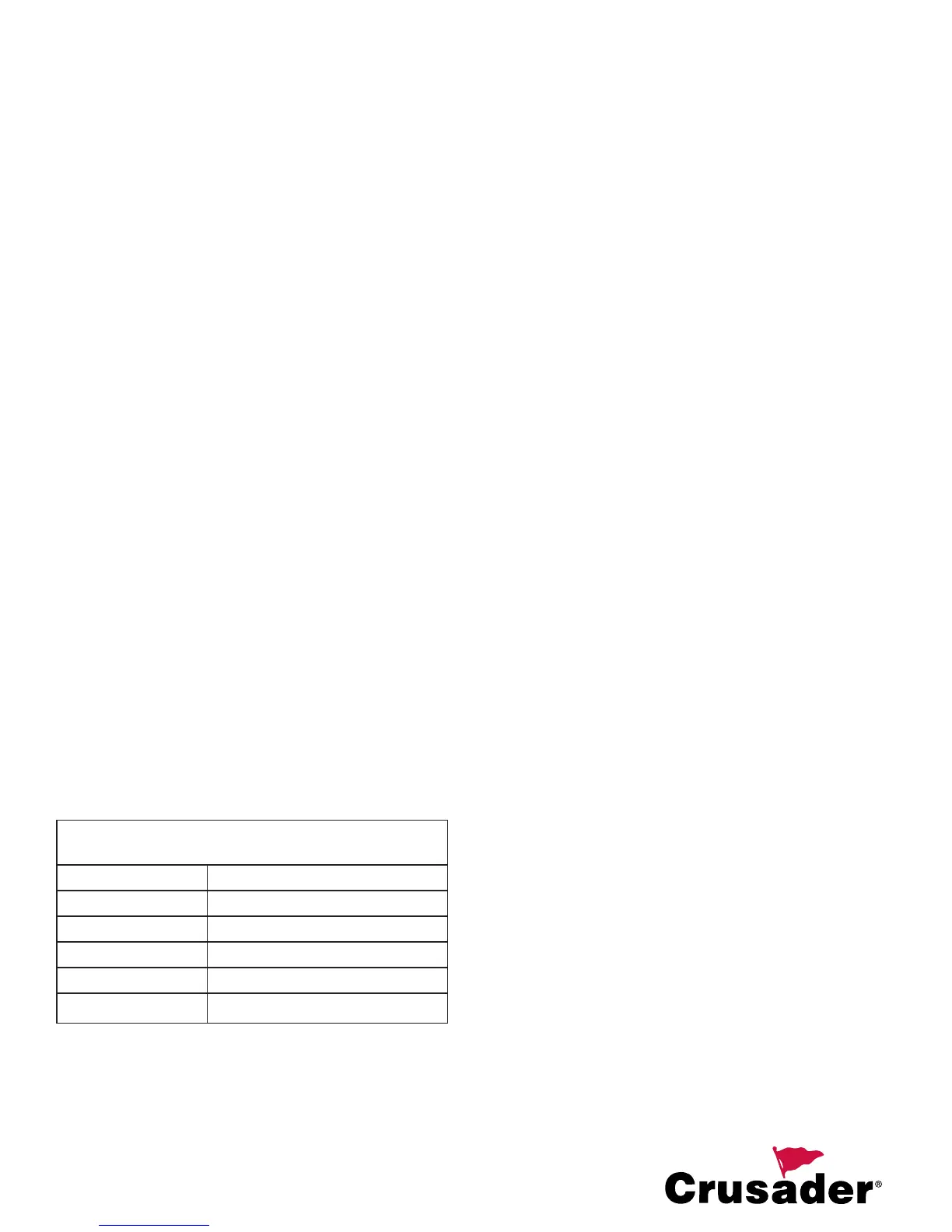

ENGINE AIR REQUIREMENTS

AT WIDE-OPEN-THROTTLE

Model Volume

MP 5.0L 670 ft

3

/min (0.320 m

3

/sec)

MP 5.7L 670 ft

3

/min (0.320 m

3

/sec)

MP 6.0L 670 ft

3

/min (0.320 m

3

/sec)

MP 8.1L STD 697 ft

3

/min (0.329 m

3

/sec)

MP 8.1L HO 697 ft

3

/min (0.329 m

3

/sec)

Air requirements listed are for single engine and

must be doubled for dual engine installations.

The pressure differential (outside engine compartment

versus inside engine compartment) should not exceed

2 in. (51 mm) of water (measured with a manometer) at

wide open throttle.

Engine Compartment & Fuel Temperature Testing

capable of operation throughout an ambient (air

temperature) range from 20° to 150°F (-7° to 65°C)

without failure. Crusader EFI and associated

components meet this standard.

Because electronic fuel injection systems require

higher fuel delivery pressures and higher volumes, fuel

temperatures become an issue. Engine compartment

temperatures have been measured in excess of 200°F

(82°C). High fuel temperatures may lead to excessive

vapor in the fuel line, particularly when gasoline

containing alcohol and the newer “reformulated” blends

are used. A maximum fuel temperature at the fuel

pump inlet of 105°F (40°C) and an ambient engine room

temperature of 150°F (65°C) must be adhered to.

To test for ambient air and fuel inlet temperature

compliance, proceed as follows:

The boat being tested should be a standard production

boat. The temperature meter used must be of a type

which can be read with the engine compartment closed.

The engine compartment is to remain closed and no air

is to be forced into the engine compartment during the

test. The bilge blower should not be running.

A. Install thermal couples 1 in. (25 mm) above each

fl ame arrestor for air temperature measurement.

B. Tee another thermal couple into the fuel line(s)

at the fuel pump inlet for measuring fuel

temperature.

C. Operate the engine(s) until engine and bilge

temperatures are stabilized. This usually

occurs when operating the engine under cruise

conditions for a minimum of one hour.

D. Shut engine(s) off and monitor temperatures

for an additional hour. Air temperature should

not exceed 150°F (65°C) and fuel temperature

should not exceed 105°F (40°C) at any time,

either during engine operation or engine off (hot

soak).

E. After the one hour hot soak test, start the

engine and let it idle (in neutral) for 20 minutes.

Continue to record temperatures for another 20

minutes.

If temperature limits are exceeded at any time during

this test, it is necessary to reevaluate the fuel system

and/or bilge ventilation and take appropriate measures

to maintain temperatures at or below the specifi ed limits

at all times.

Loading...

Loading...